All-in-one machine capable of simultaneously producing high quality distilled water and pure steam

A pure steam and distilled water technology, applied in the field of all-in-one machines that simultaneously produce high-quality distilled water and pure steam, can solve the problems of occupying the area and space of the plant, increasing equipment purchase costs, and reducing the output of distilled water, so as to save plant space and occupy less , The effect of reducing material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

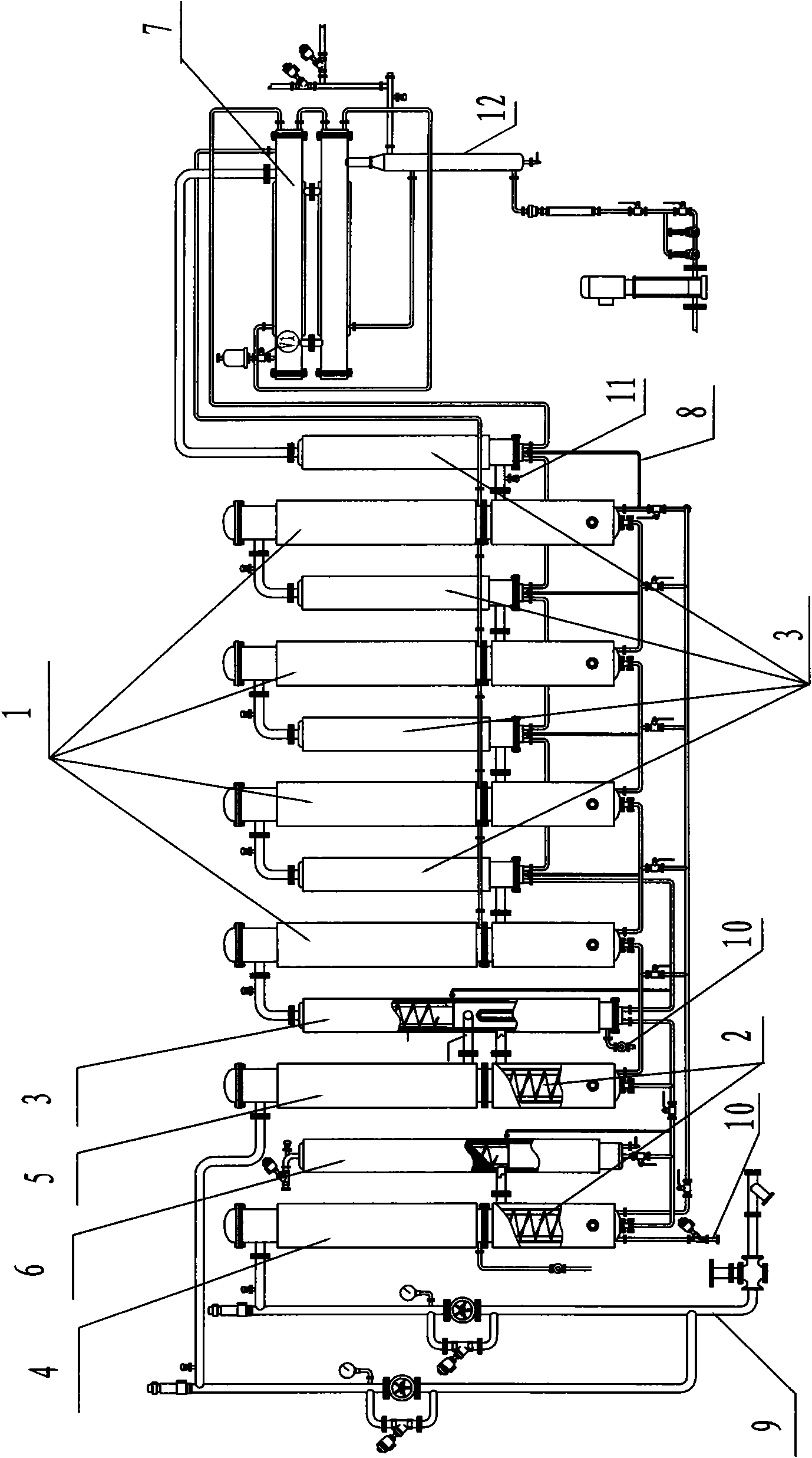

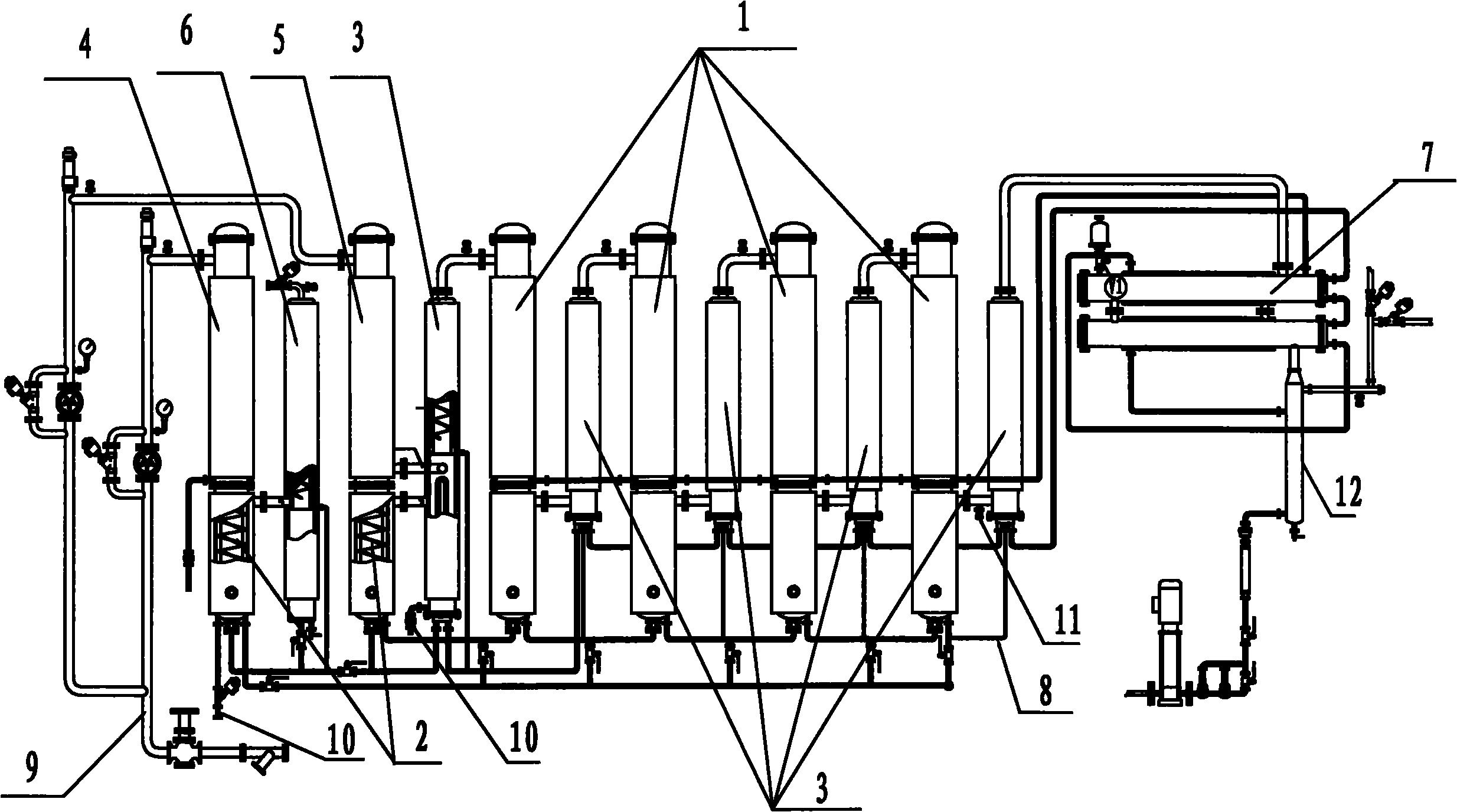

[0014] As shown in the attached figure, an integrated machine that simultaneously produces high-quality distilled water and pure steam includes multiple shell-and-tube falling film evaporators 1, multiple double external spiral separators 2, and multiple U-shaped external spiral separators for preheating 3, at least one condenser 7, two secondary steam generators 4, 5, pure steam outer spiral separation steam storage cylinder 6, raw water pipeline 8 and raw steam pipeline 9, the tube-and-tube falling film evaporator The lower part of 1 and the lower part of the secondary steam generators 4 and 5 are all in communication with the double external spiral separator 2, and the first tube falling film evaporator 1 is provided with a boiler raw steam inlet and a secondary steam outlet, The rest of the falling film evaporators 1 are provided with a secondary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com