Concrete maintenance material and preparation method thereof

A technology of concrete and gauze, which is applied in the manufacture of tools, ceramic molding machines, textiles and papermaking, etc., can solve the problems of poor early micro-crack effect, and achieve the effect of wide application range, convenient use, and control of micro-cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

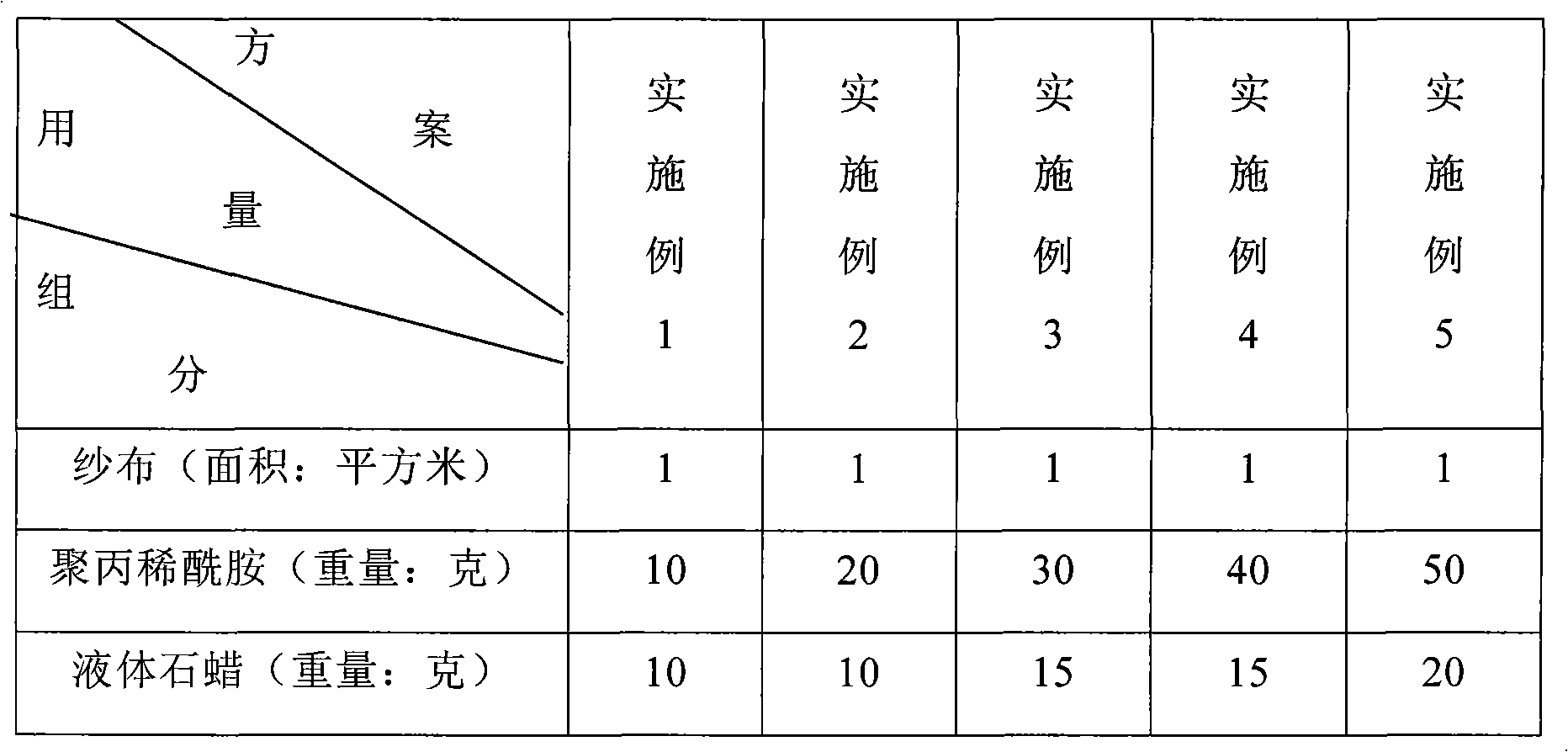

[0022] Prepare a series of concrete curing materials according to the ratio of raw materials in Table 1.

[0023] Table 1 The formula of the air-entrained concrete air-generating material

[0024]

[0025] According to Example 2 in Table 1, the material of the present invention was prepared according to the steps of the above-mentioned material preparation method, denoted as YH.

[0026] Beneficial effect

[0027] The beneficial effect of the material of the invention is tested by adopting the method of quickly testing the concrete curing effect under the environment of strong drying and blowing. The specific method is to prepare 2 parts of cement slurry according to the water-cement ratio of 0.5, and then fill the 2 parts of the slurry into 2 square trays of the same size. Roughed to a matte finish to provide greater restriction on volume changes of the cement paste. Cover the material YH of the present invention on the grout surface of one of the trays, and then use an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com