Double-layer flame electric fireplace

An electric fireplace and flame technology, which is applied in the field of double-layer flame electric fireplace, can solve the problems of less flame layers, small depth range, and poor three-dimensional effect, and achieve the effect of improving the simulation level, large depth range, and strong three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

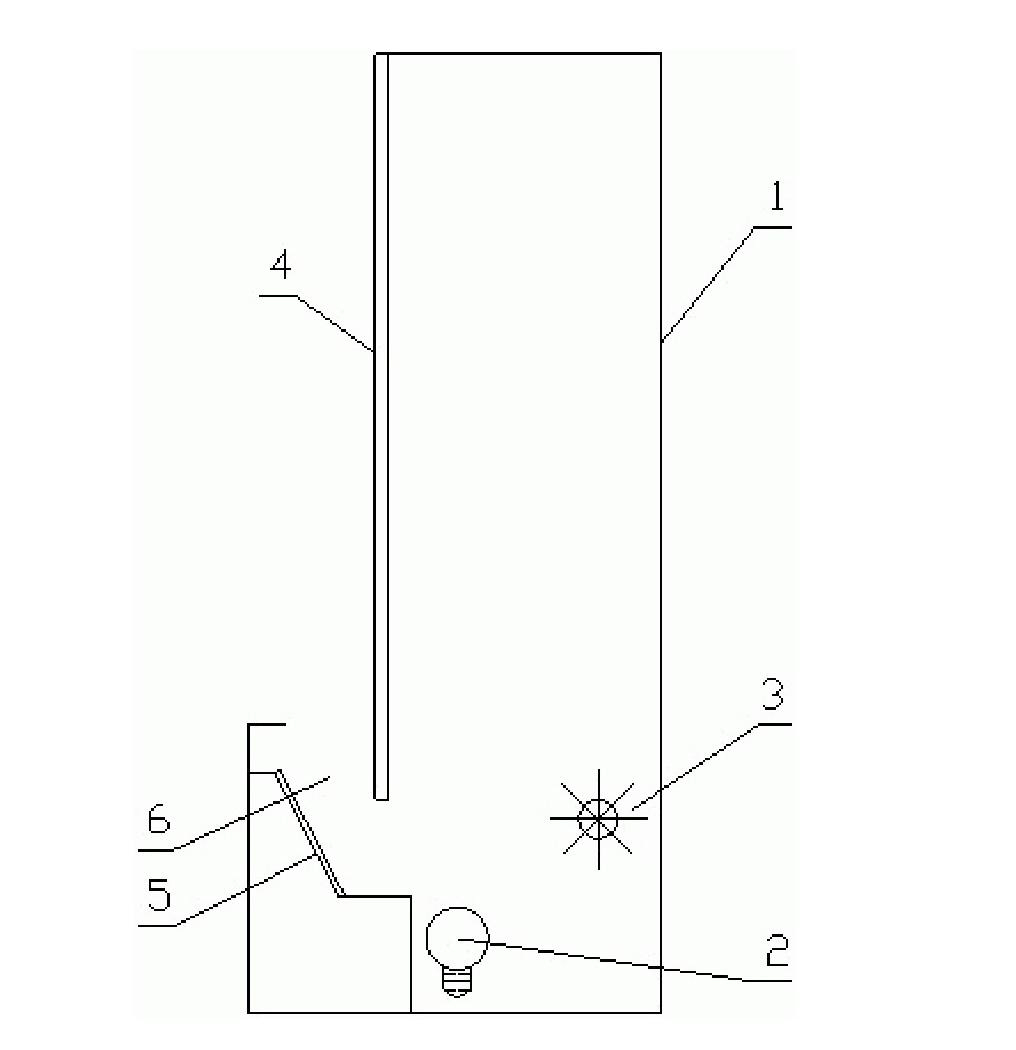

[0023] in such as figure 1 In the shown embodiment 1, a double-flame electric fireplace includes a housing 1, an imaging light source 2, a light processing device 3, and an imaging screen 4. The light from the imaging light source is irradiated to the back of the imaging screen of the electric fireplace through the light processing device On the surface, a reflective device 5 is also provided under the front side of the imaging screen. The reflective device is a reflective plate, and the reflective surface of the reflective plate is a fully reflective planar structure, forming an included angle with the height direction of the imaging screen as a whole. A light passage 6 is provided between the reflective device and the imaging screen, and the light from the imaging light source of the electric fireplace is irradiated onto the front surface of the imaging screen of the electric fireplace through the reflective device.

Embodiment 2

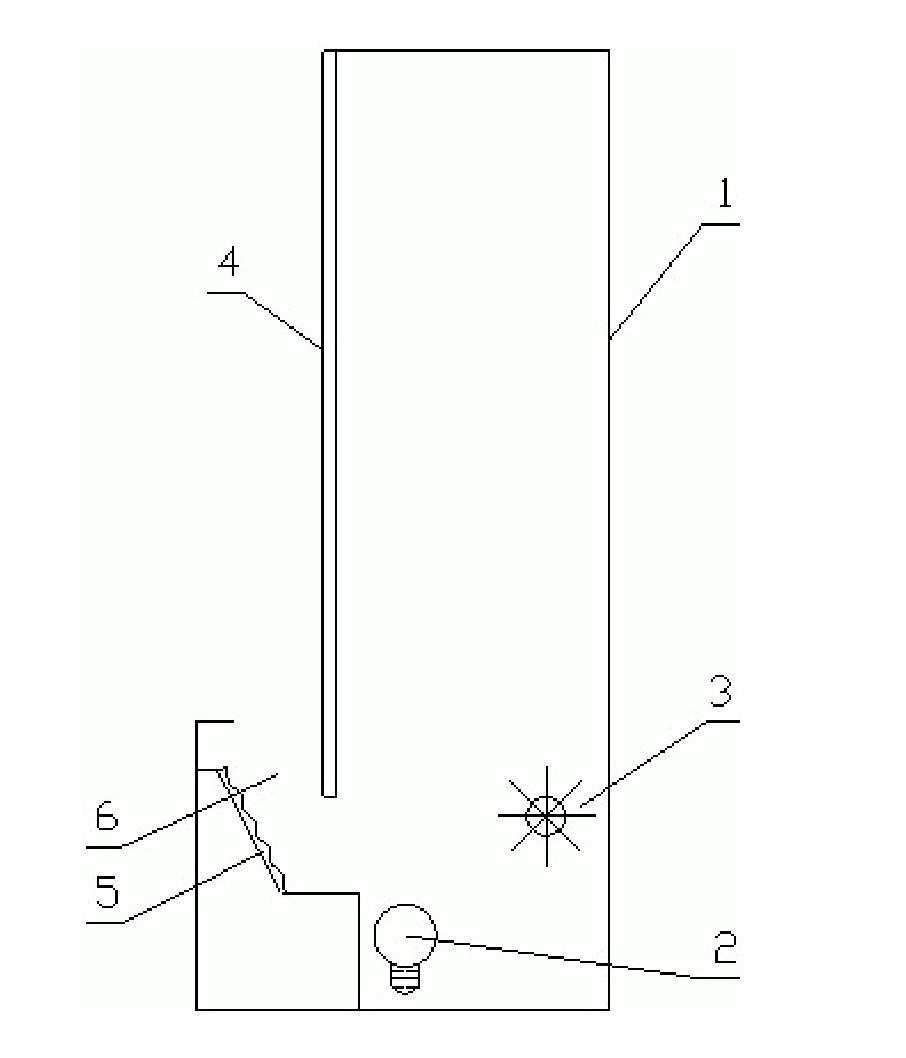

[0025] The reflective device of embodiment 2 is a reflector, and the reflective surface of the reflector is a curved surface structure with some concavo-convex surfaces (see figure 2 ), all the other are identical with embodiment 1.

Embodiment 3

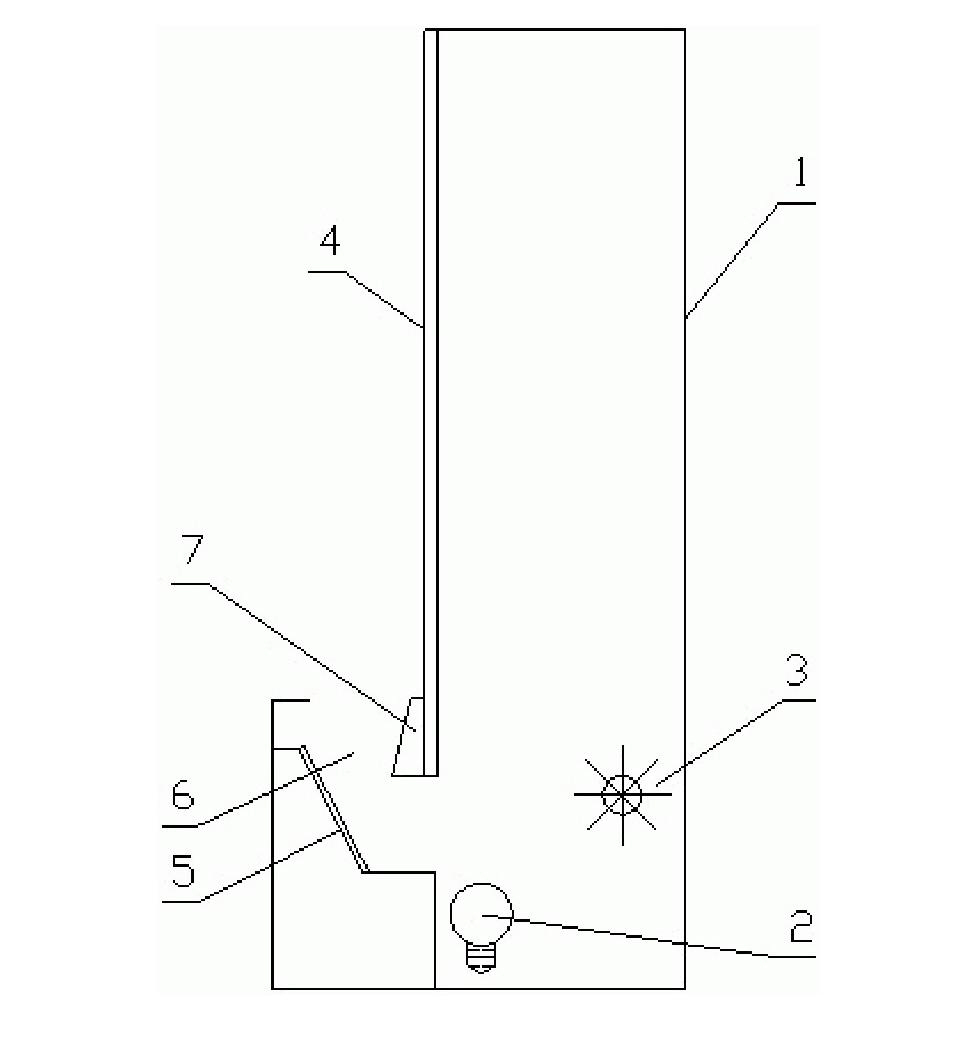

[0027] in such as image 3 In the shown embodiment 3, a simulated charcoal bed 7 is provided under the front side of the electric fireplace imaging screen, and a plurality of reflective structures 8 are provided on the front surface of the simulated charcoal bed, and the light channel 6 is arranged on the front side of the simulated charcoal bed , the light of the imaging light source of the electric fireplace is irradiated onto the reflective structure of the simulated carbon bed through the reflective device. The reflective structure is a reflective film, which is pasted on the surface of the simulated carbon bed (see Figure 8 ), the profile of the reflective film is polygonal, and the reflective area of the reflective structure varies in size, between 0.1 and 0.5 square centimeters, and the reflective device is a partially reflective plane reflector, and all the other are the same as in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com