Device for simulation of coal spontaneous combustion on basis of programmed temperature control

A simulation device, coal spontaneous combustion technology, applied in the direction of fuel oil testing, material inspection products, etc., can solve problems such as difficulty in researching heating characteristics, large coal sample volume, and difficulty in spontaneous combustion of coal, and achieve high-precision results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

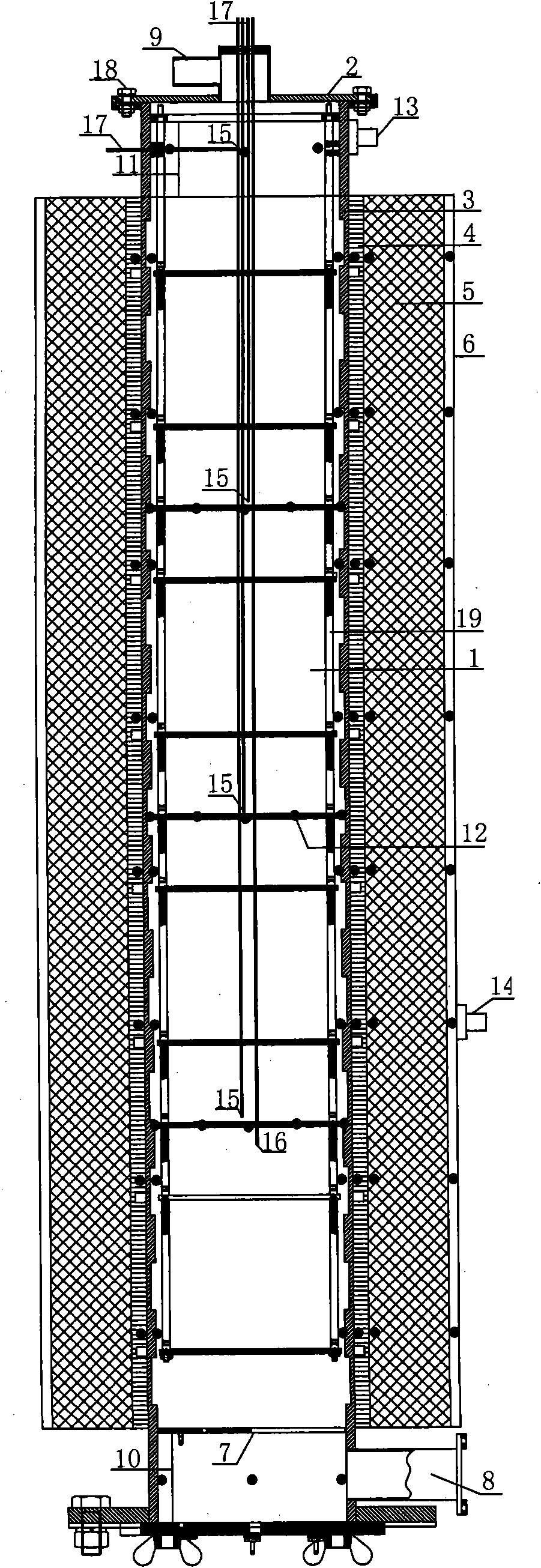

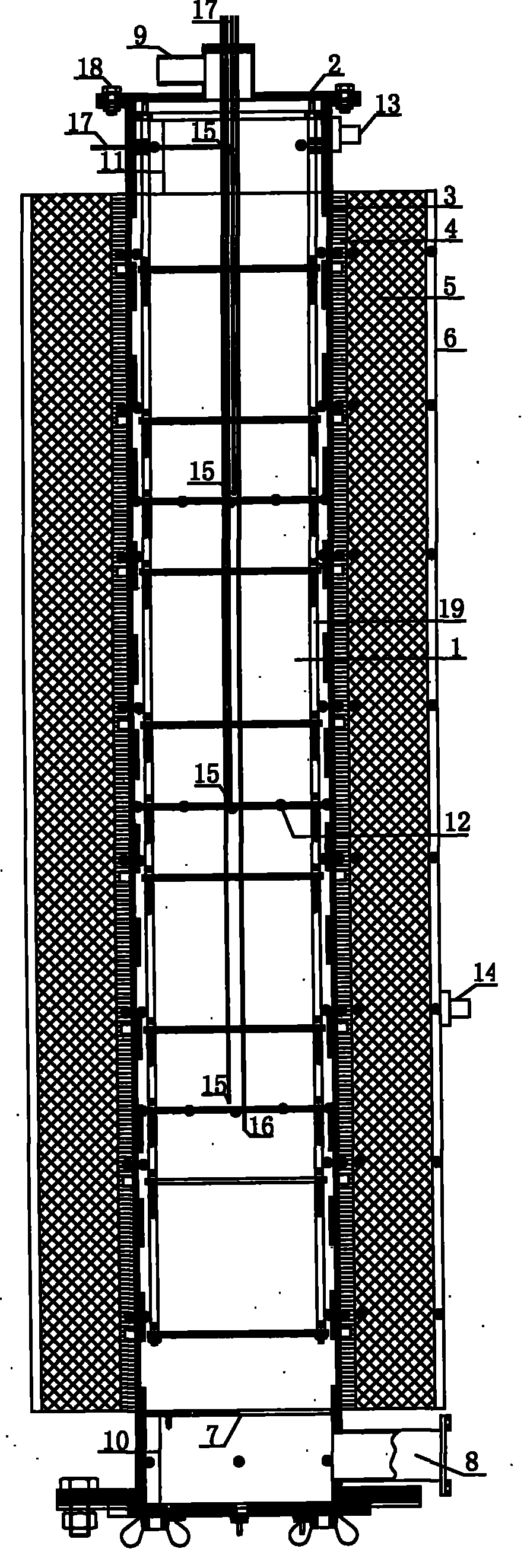

[0016] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

[0017] The invention builds a coal spontaneous combustion process with a moderate coal loading capacity that can approximately simulate the actual coal yard's air leakage intensity, floating coal thickness and heat storage conditions, and can reflect the distribution of the temperature field and index gas concentration field during the coal spontaneous combustion process, and realize the test The cycle is short and the test cost is low.

[0018] In the coal spontaneous combustion simulation device based on program temperature control of the present invention, the inner and outer walls of the reaction cylinder are successively composed of stainless steel plates, electric heating belts, thermal insulation material layers and packaging iron sheets, and the stainless steel plates on the inner wall of the reaction cylinder are made of threaded shapes. , There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com