2*2 long period fiber bragg grating coupler

A fiber grating and coupler technology, applied in the coupling of optical waveguide, cladding fiber, optical waveguide light guide, etc., can solve the problem of non-reconfigurable and achieve the effect of easy writing and erasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

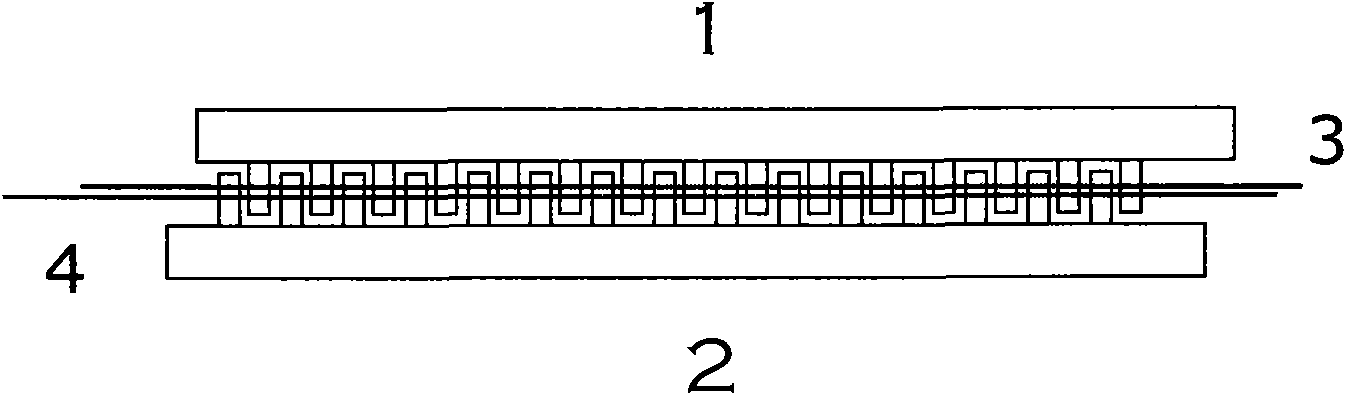

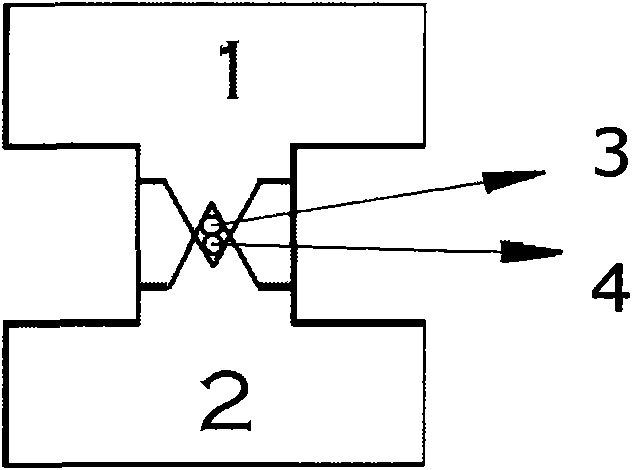

[0037] figure 1 It is a structural diagram of a specific embodiment of the 2×2 long-period fiber grating coupler of the present invention.

[0038] In this embodiment, the reconfigurable 2×2 long-period fiber grating coupler of the present invention can be implemented according to the following steps:

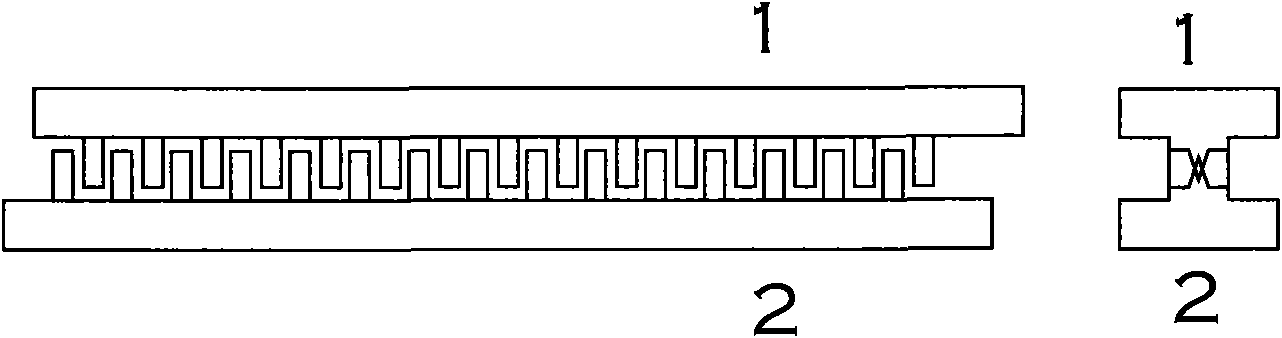

[0039] Step 1: Manufacture two toothed force applying units 1 and 2 with V-shaped grooves with the same specific period by machining, such as Figure 4 shown.

[0040] Step 2: Put two bare fibers 3 and 4 into Figure 4 In the V-shaped groove of the force application unit 2 shown, another force application unit 1 is placed above, that is, the V-shaped periodic grooves of the two force application units 1 and 2 are inserted into each other and simultaneously press the two bare optical fibers 3 and 4 ,Such as figure 1 and figure 2 shown. This structure ensures that the two bare optical fibers 3 and 4 clamped in the two V-shaped periodic grooves can be in close contact, and ...

Embodiment 2

[0043] Figure 5 It is a transmission coupling characteristic diagram under a specific implementation mode of the 2×2 long-period fiber grating coupler of the present invention.

[0044] In the present embodiment, the long-period grating period Λ=0.6mm produced by the periodic radial pressure, according to the test, the fundamental mode of the core and the third-order cladding mode in the common single-mode fiber near the wavelength of 1550nm satisfy (1) formula conditions. We used two toothed force applying units with V-shaped grooves, and clamped two bare optical fibers according to the steps in Embodiment 1. The parameters of the V-shaped periodic groove are: period 0.6mm, tooth width 0.2mm, and 100 pressing teeth. When the photoelastic effect and microbending effect under the pressure of 2.5Kg heavy objects cause the fiber to produce long-period fiber gratings, the grating couples the fundamental mode of the fiber core with the third-order cladding mode, and the evanesce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com