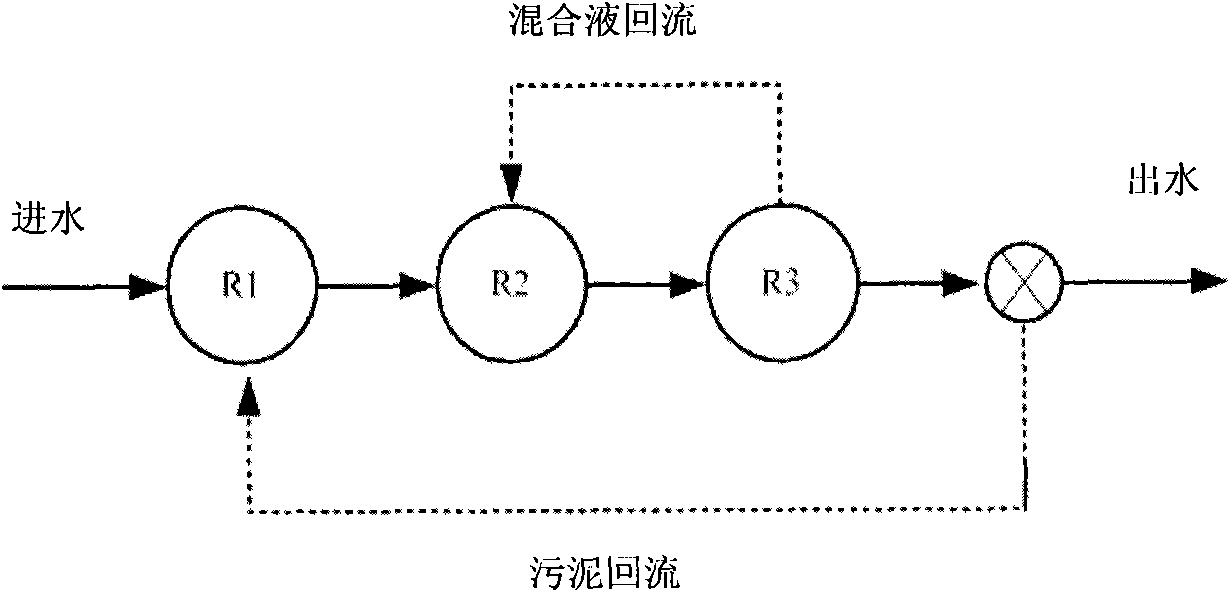

Optimization design method of sewage treatment plant A2/O process

A technology of sewage treatment plant, optimized design, applied in general water supply saving, electrical digital data processing, special data processing applications, etc., can solve problems such as not being optimized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

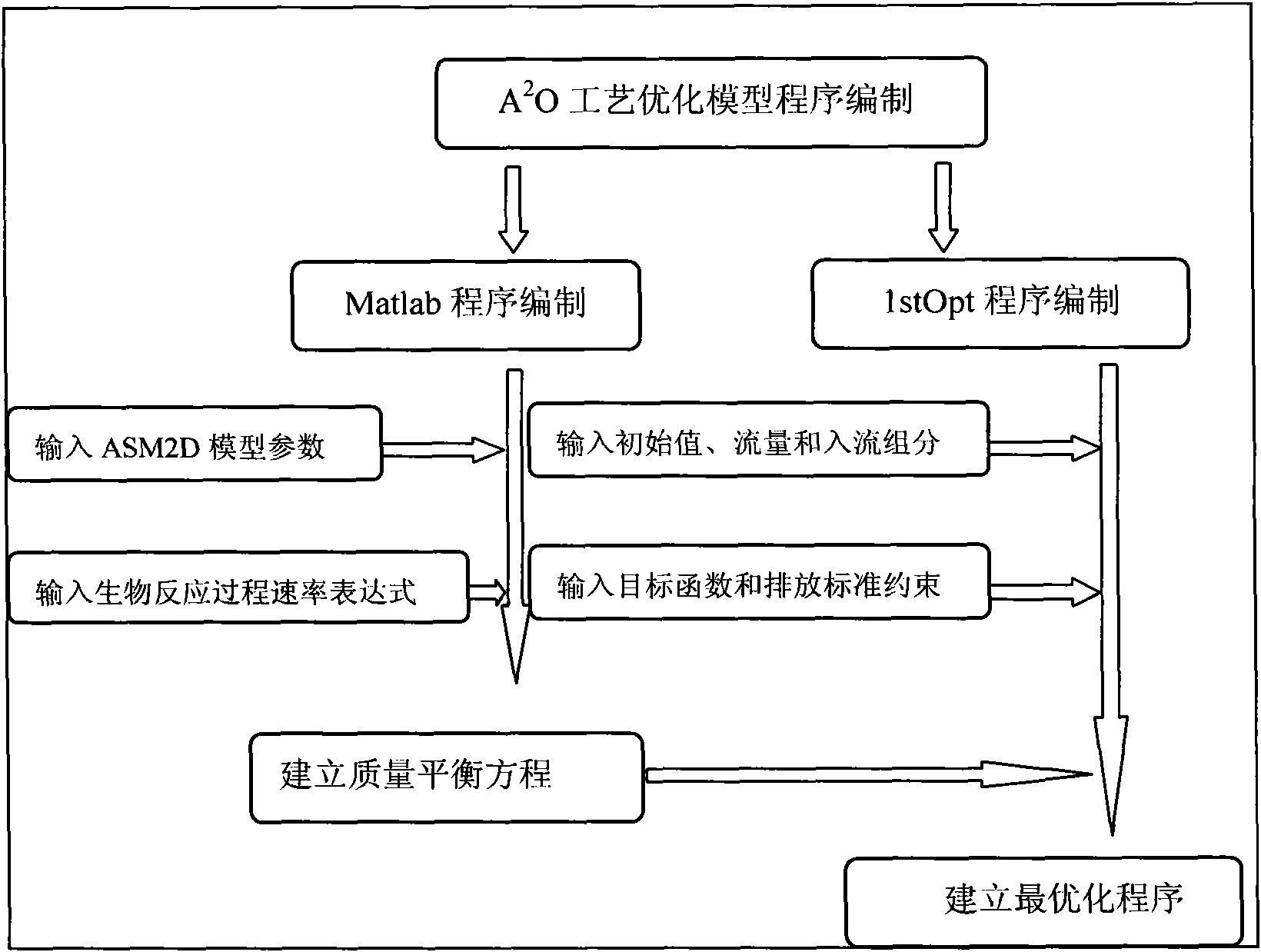

Method used

Image

Examples

Embodiment 1

[0075] Example 1: Design a sewage plant in East China with a flow rate of 570,000 m 3 / d, use A 2 / O process. It covers an area of about 29.66ha, and the working water temperature is 15°C; the influent and effluent water quality requirements are shown in Table 2, and the first-class B standard in the comprehensive sewage discharge standard (GB18918-2002) is used as the design effluent standard, and the model components are converted to conventional influent indicators The typical classification standard of the International Water Quality Association is adopted.

[0076] Table 2A Conventional Influent Index of Sewage Plant (mg / l)

[0077]

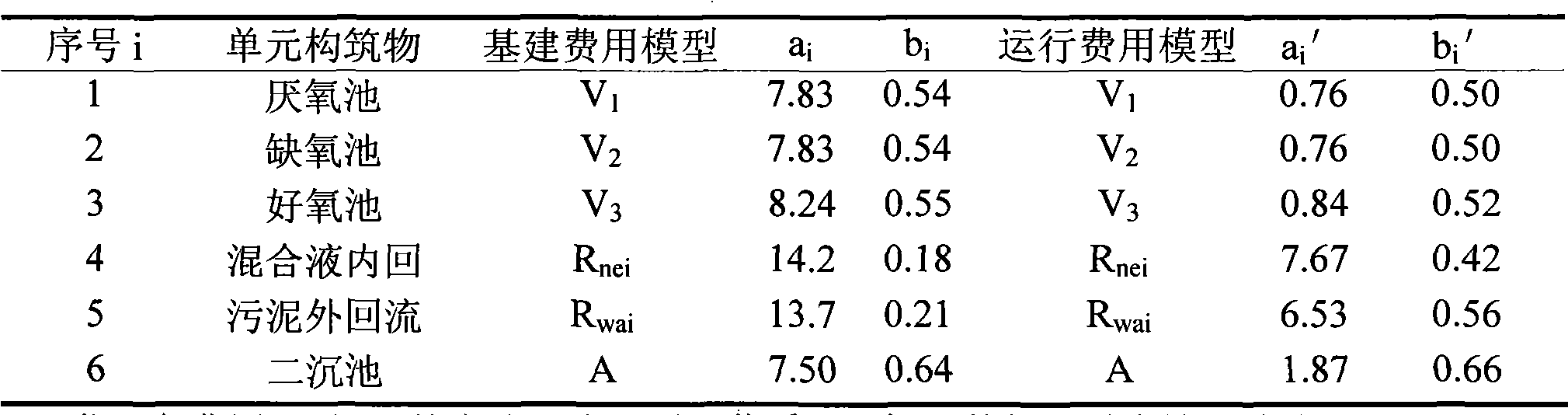

[0078] Firstly, establish the cost objective function of A sewage plant, namely:

[0079] f = ω 1 ( a 1 V 1 b 1 + ...

Embodiment 2

[0101] Example 2: Design a sewage plant in South China, covering an area of 11.6ha, which was completed and put into operation in 1996. It mainly treats the urban sewage intercepted by the urban drainage system in this area. The treatment process is typical A 2 / O method, the treated sewage is discharged into the nearby natural water body. The project processing scale is 150,000 m 3 / d, the design hour average flow rate is 4167m 3 / h. The design total variation coefficient is K=1.1, the working water temperature of the sewage plant is 20°C, and the requirements for influent and effluent water quality indicators are shown in Table 4, and the first-class B standard in the comprehensive sewage discharge standard (GB18918-2002) is used as the design effluent standard.

[0102] Table 4 Conventional water inflow index of B sewage plant (mg / l)

[0103]

[0104] First, establish the cost objective function of B sewage plant, namely:

[0105] f = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com