Full-automatic lifting hospital bed and control method

A medical bed, fully automatic technology, applied in the direction of hospital beds, medical science, hospital equipment, etc., can solve the problems of small angle space, affecting physical recovery, complex structure, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

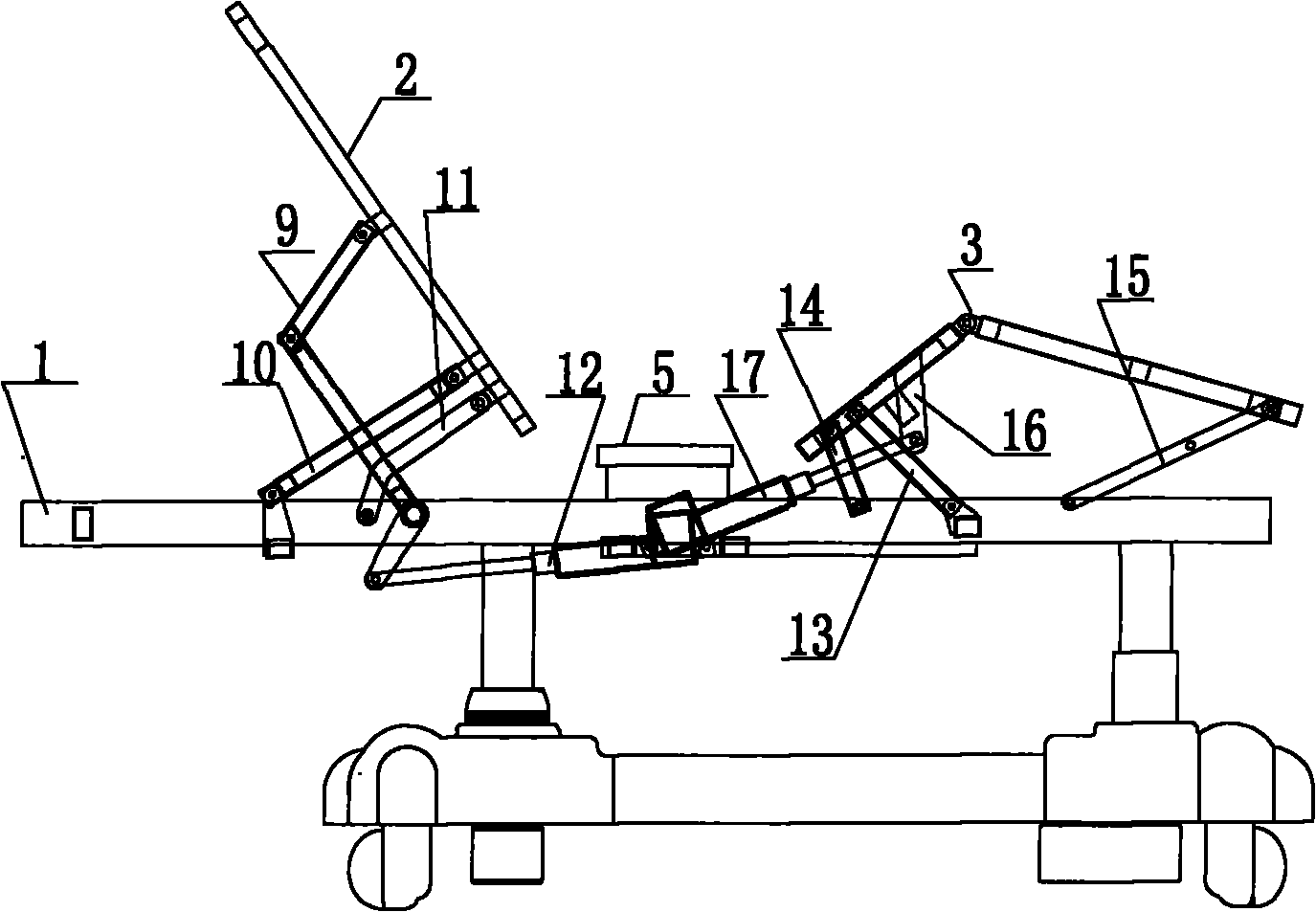

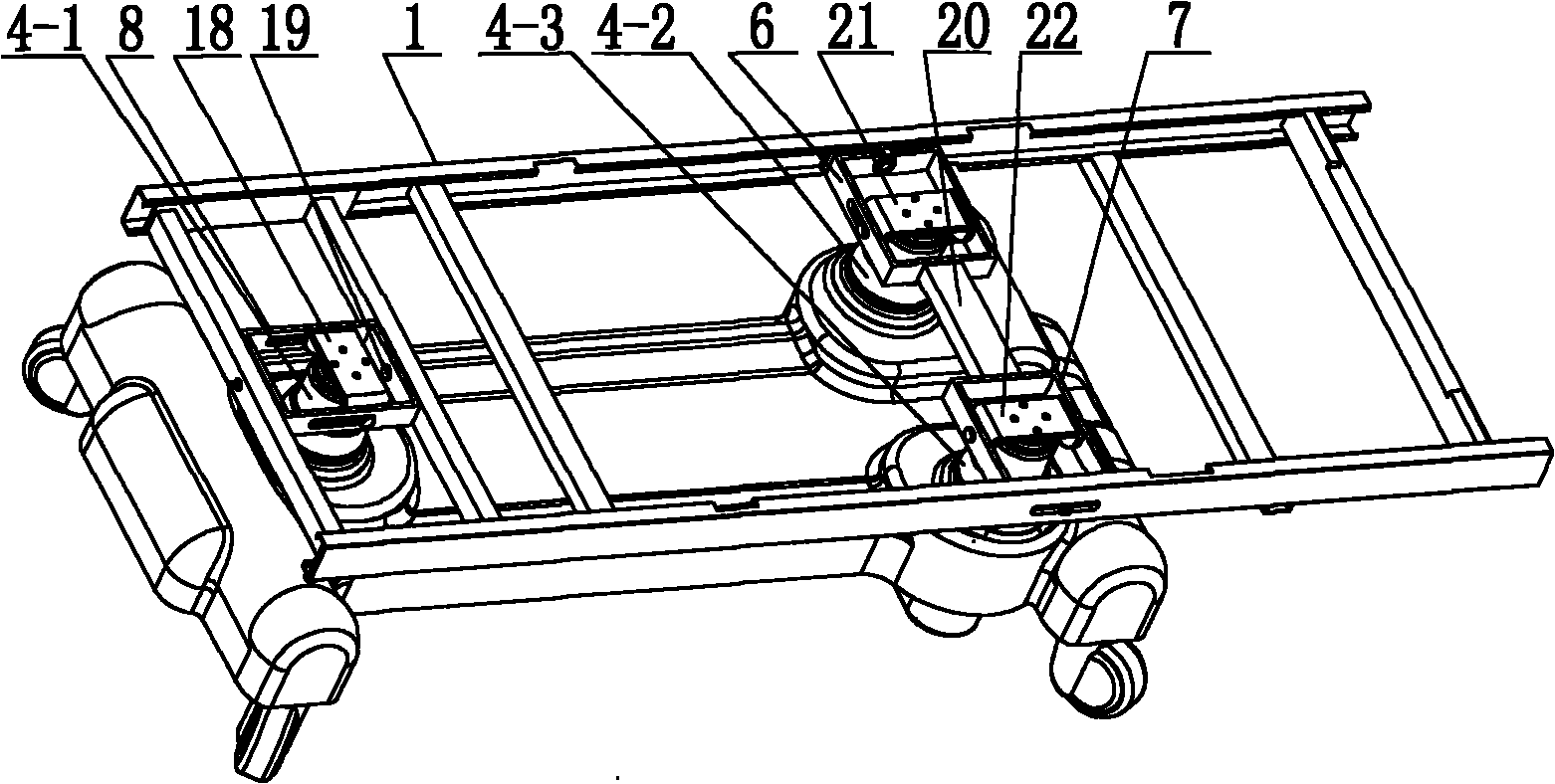

[0014] Embodiment 1: with reference to attached Figure 1~4 . A fully automatic lifting medical bed, which includes a bed frame 1, a back frame 2, a leg frame 3, a bed frame chassis 4 and a program controller. The bed frame chassis 4 is distributed with three cylindrical lifting motors 4 in an isosceles triangle -1 to 4-3 are respectively connected to the bed frame 1 located thereon through respective frame-shaped universal joints 8 and conjoined universal joints 6 and 7, the fixed frame plate 5 is fixed on the middle part of the bed frame 1, and the back frame 2. The leg frame 3 is respectively located on both sides of the fixed frame plate 5, and the back frame 2 and the bed frame 1 respectively pass through the multi-stage hinged power lifting arm 9, the hinged sliding arm 10 and the sliding frame located in the middle of the back frame 2. The arm 11 is hinged, and the leg board frame 3 and the bed frame 1 are respectively hinged by the leg board hinge arm 13, the short mo...

Embodiment 2

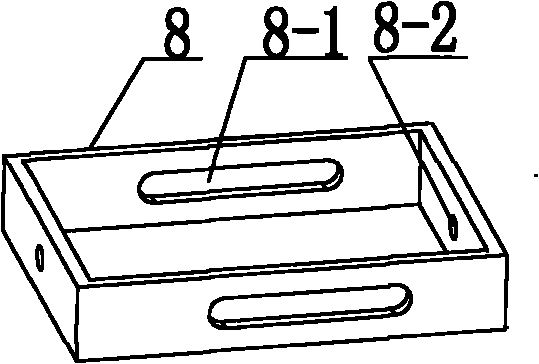

[0015] Embodiment 2: with reference to attached Figure 5 and 6 . On the basis of embodiment 1, the control method of the fully automatic lifting medical bed includes a program controller, (1) the front and rear inclination of the bed frame 1: ① the program controller instructs the front and rear cylindrical lifting motors that are hingedly connected with the bed frame 1 4-1 When stretching out, the conjoined universal joints 6 and 7, which are hingedly connected to the bed frame 1 at the rear, use their hinged pin shafts as the rotating shafts. When the front part of the bed frame 1 is raised or lowered, its The pin shaft slides in the long sliding holes 8-1 on both sides of the frame universal joint 8, which realizes the front and rear tilting of the bed frame 1; 3 When lifting and lowering at the same time, the front of the bed frame 1 takes the connecting pin shaft at the front of the bed frame 1 as the rotating shaft, and the cylindrical lifting motor 4-2 and the cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com