Aeration nozzle for sewage treatment

A sewage treatment and nozzle technology, applied in water aeration, water/sludge/sewage treatment, aerobic process treatment, etc., can solve problems such as high back pressure, large gas loss, gas reactive power waste, etc., to prevent sedimentation The effects of sedimentation, gas-liquid contact area increase, and dissolved oxygen increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

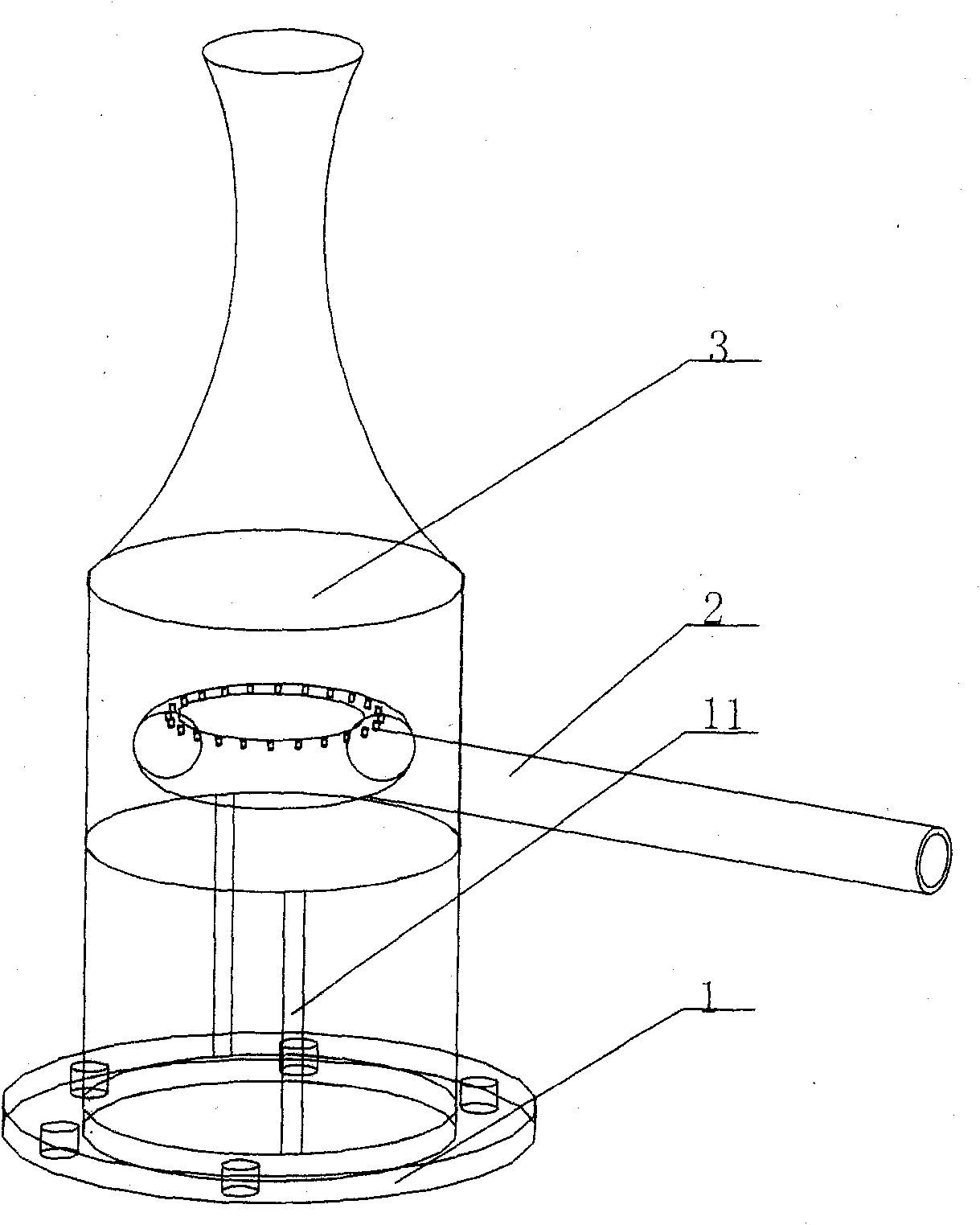

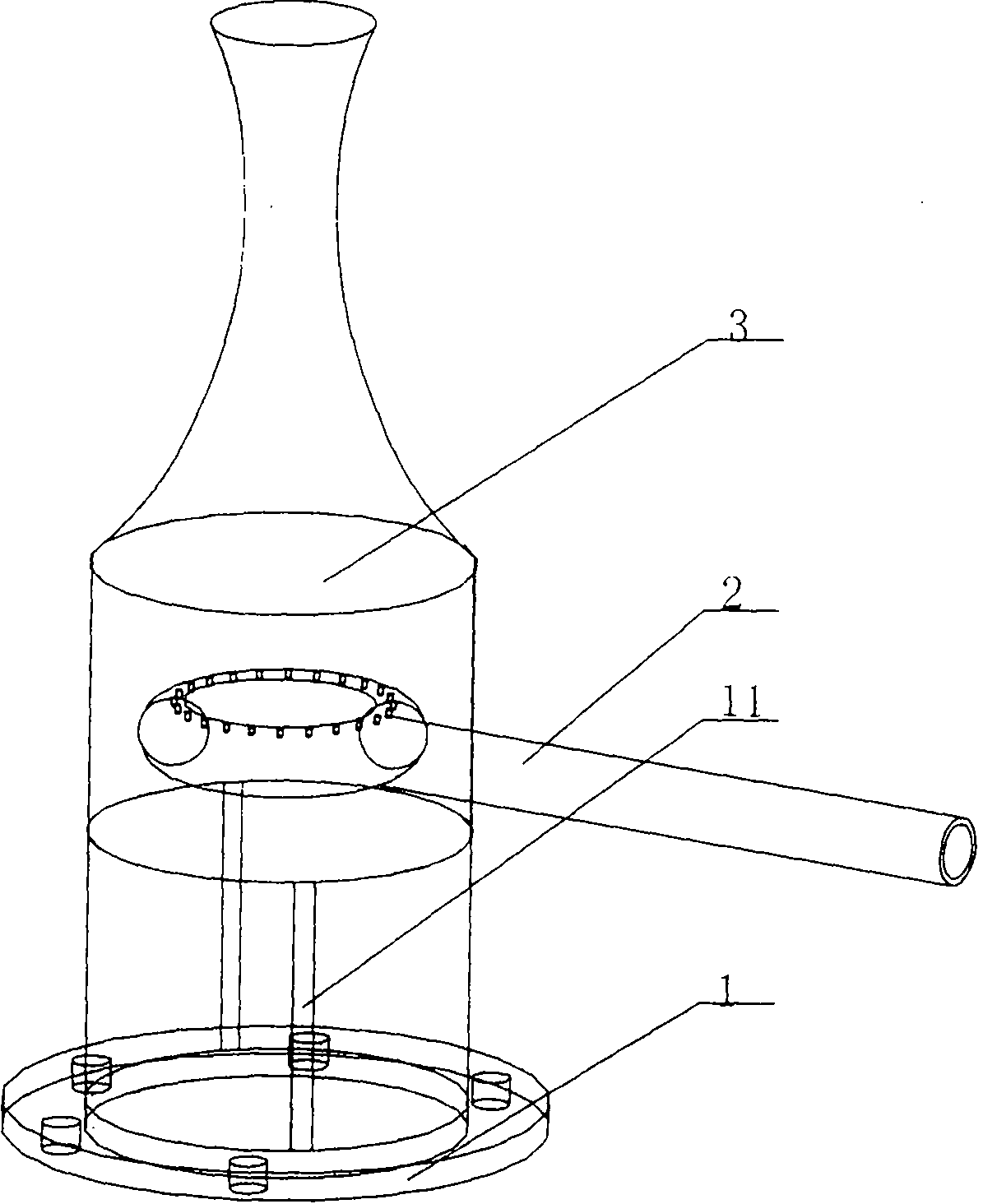

[0012] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0013] like figure 1 The sewage treatment aeration nozzle shown in the best mode has an annular flange-shaped base 1, an air supply nozzle 2 and a gas-liquid mixing guide tube 3, and the base 1 is provided with a support frame 11, and the support frame 11 is four And the diameter is 12mm, the gas-liquid mixing guide tube 3 is fixed on the support frame 11, the air supply nozzle 2 is arranged in the guide tube and the nozzle of the air supply nozzle 2 extends radially out of the guide tube.

[0014] The gas-liquid mixing guide tube 3 is an inverted waist drum type, which gradually shrinks from bottom to top and then expands. The ratio of the lower opening to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com