Heat treating equipment for rocker arm shaft of automobile engine

A technology for heat treatment equipment and automobile engines, applied in heat treatment equipment, heat treatment furnaces, furnace types, etc., can solve the problems of difficult implementation of mass production, lack of mature technology, and difficult heat treatment process, etc., and achieve high degree of automation and fast feeding , The effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

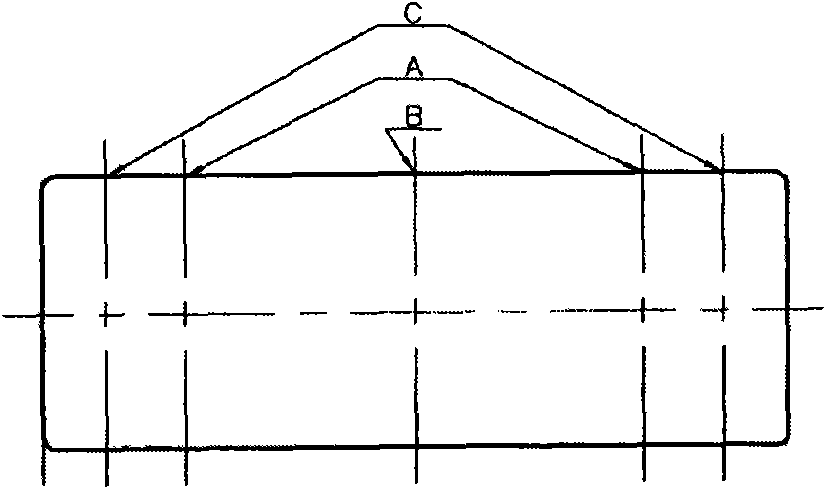

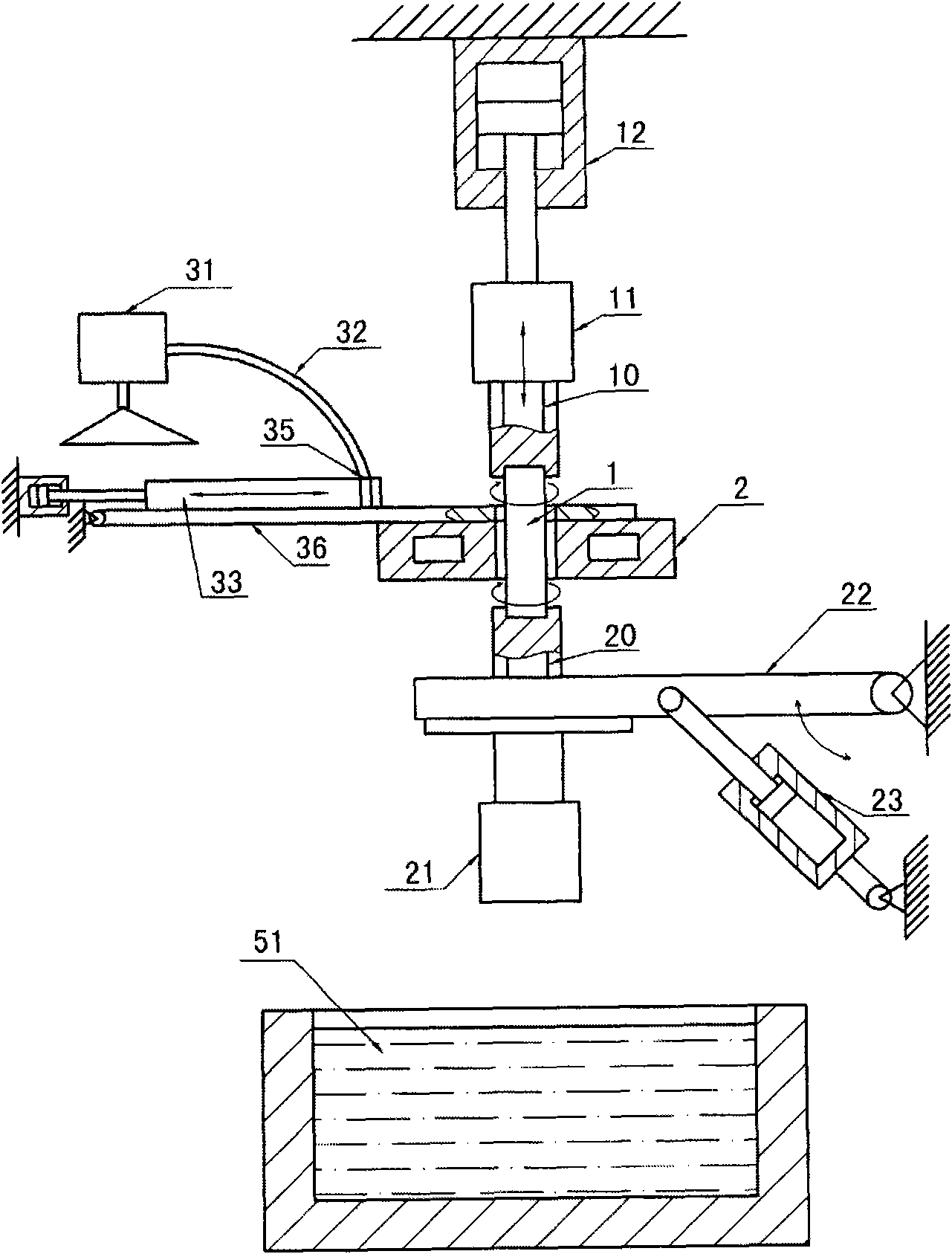

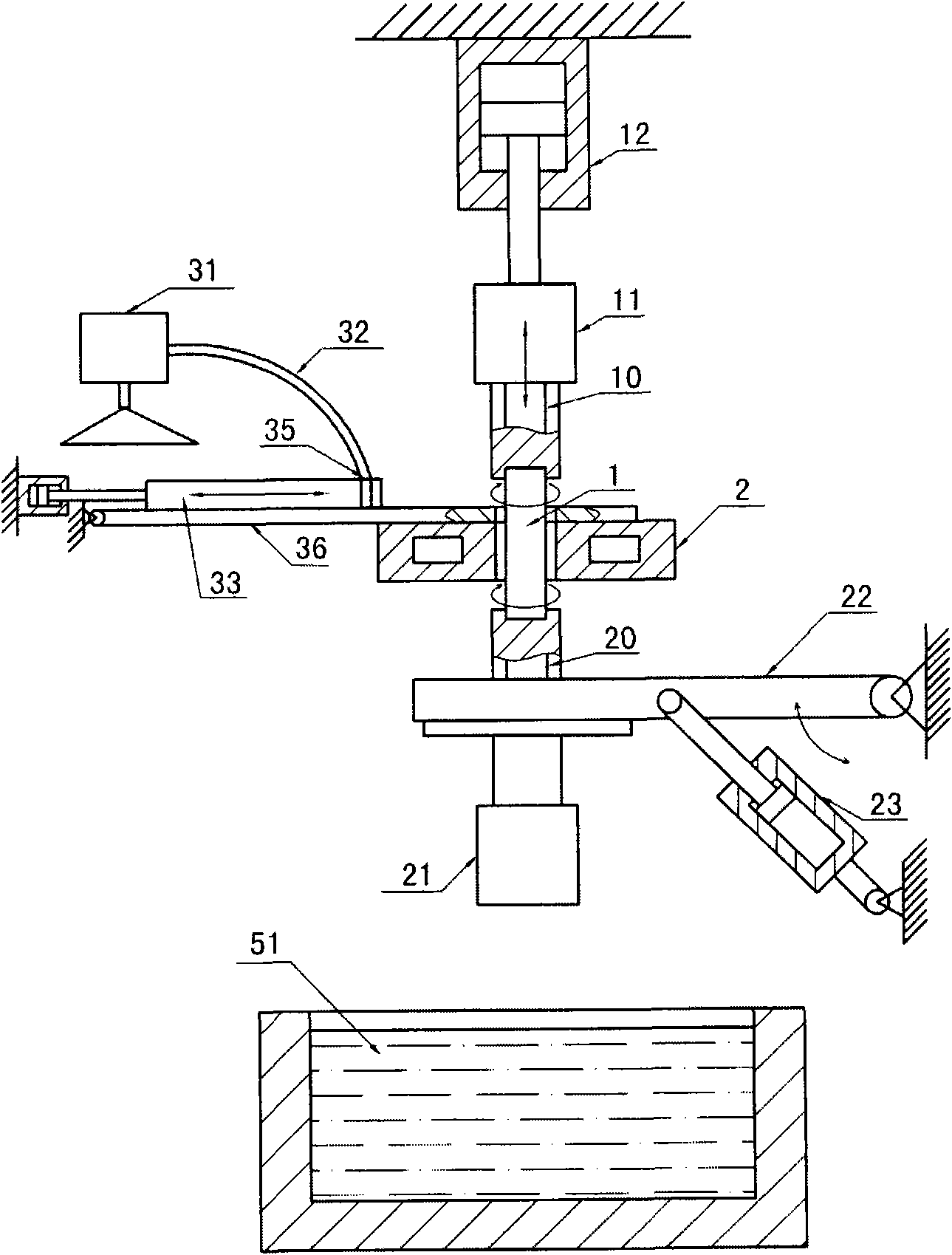

[0024] Example: such as figure 2 As shown, a heat treatment equipment for an automobile engine rocker shaft includes: a workpiece feeding device, a high-frequency heating induction coil 2 for high-frequency heating of a workpiece 1 to be processed, and a positioning mechanism for clamping and positioning the workpiece 1 to be processed.

[0025] The positioning mechanism includes an upper positioning shaft 10 arranged directly above the high-frequency heating induction coil 2 for clamping the workpiece 1 to be processed, and a lower shaft 10 arranged directly below the high-frequency heating induction coil 2 for clamping the workpiece 1 to be processed. Position axis 20. The upper positioning shaft 10 and the lower positioning shaft 20 clamp and limit the workpiece 1 to be processed in the center of the high-frequency heating induction coil 2 by two upper and lower positions.

[0026] The upper positioning shaft 10 is provided with an upper rotating motor 11 which can make t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com