Method for processing and building overhauling working lining bricks of vertical type vacuum refining furnace hearth

A technology of vacuum refining furnace and working layer, applied in the field of metallurgical furnace, can solve the problems of large workload of processing bricks, affecting work efficiency, increasing labor intensity of workers, etc., so as to reduce labor volume, improve work efficiency, and simplify construction procedures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

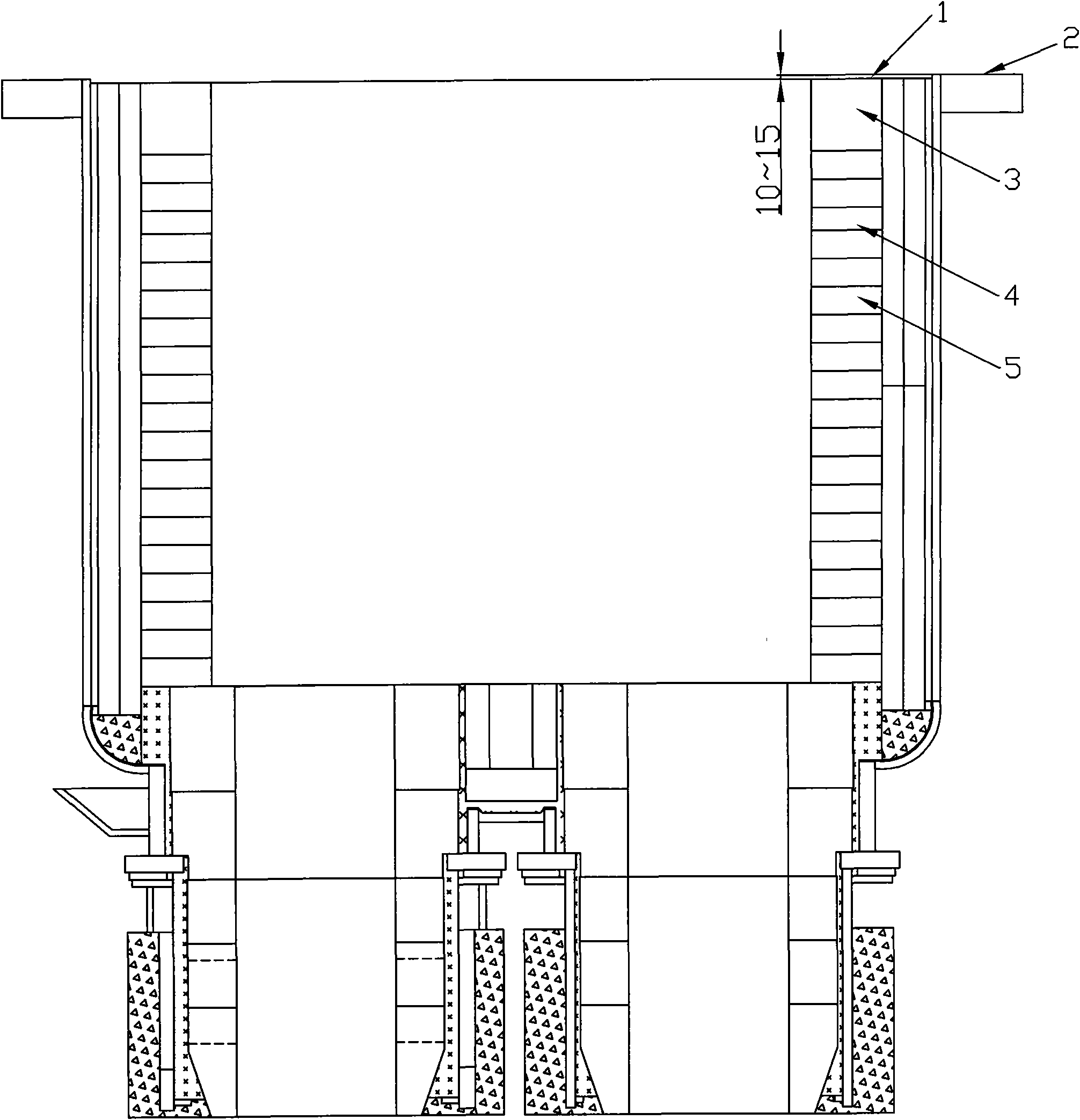

[0016] The method and related technical problems of the present invention will be described in further detail below in conjunction with the accompanying drawings. As attached figure 1 Shown is an embodiment of the applicant. In this example, the lock brick 3 is the 20th layer of the bottom lining, and the cut working layer brick 4 is the 17th layer. The lock brick 3 is the standard lock brick with the standard numbers 2GG16 and 2GG10, and the cut working layer brick 4 and the working layer brick 5 are the standard working layer bricks with the standard numbers 25 / 60 and 25 / 16. The aforementioned lock brick 3, cut working layer brick 4 and working layer brick 5 are all standard products in the prior art. When the method of the present invention is adopted, since the lock brick 3 is no longer cut, the working layer brick 5 of the third or fourth layer below the lock brick 3 is cut instead, so that the original lock brick 2GG10 and 2GG16 are processed as a ring 117 The block has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com