A Single Locomotive Fixed Rolling Test Bench

A rolling test bench and locomotive technology, applied in railway vehicle testing and other directions, can solve the problems of unstable locomotive operation, high requirements for test workshops, dynamic instability, etc., achieve simple, effective and reliable synchronization, shorten test preparation time, and work speed range. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

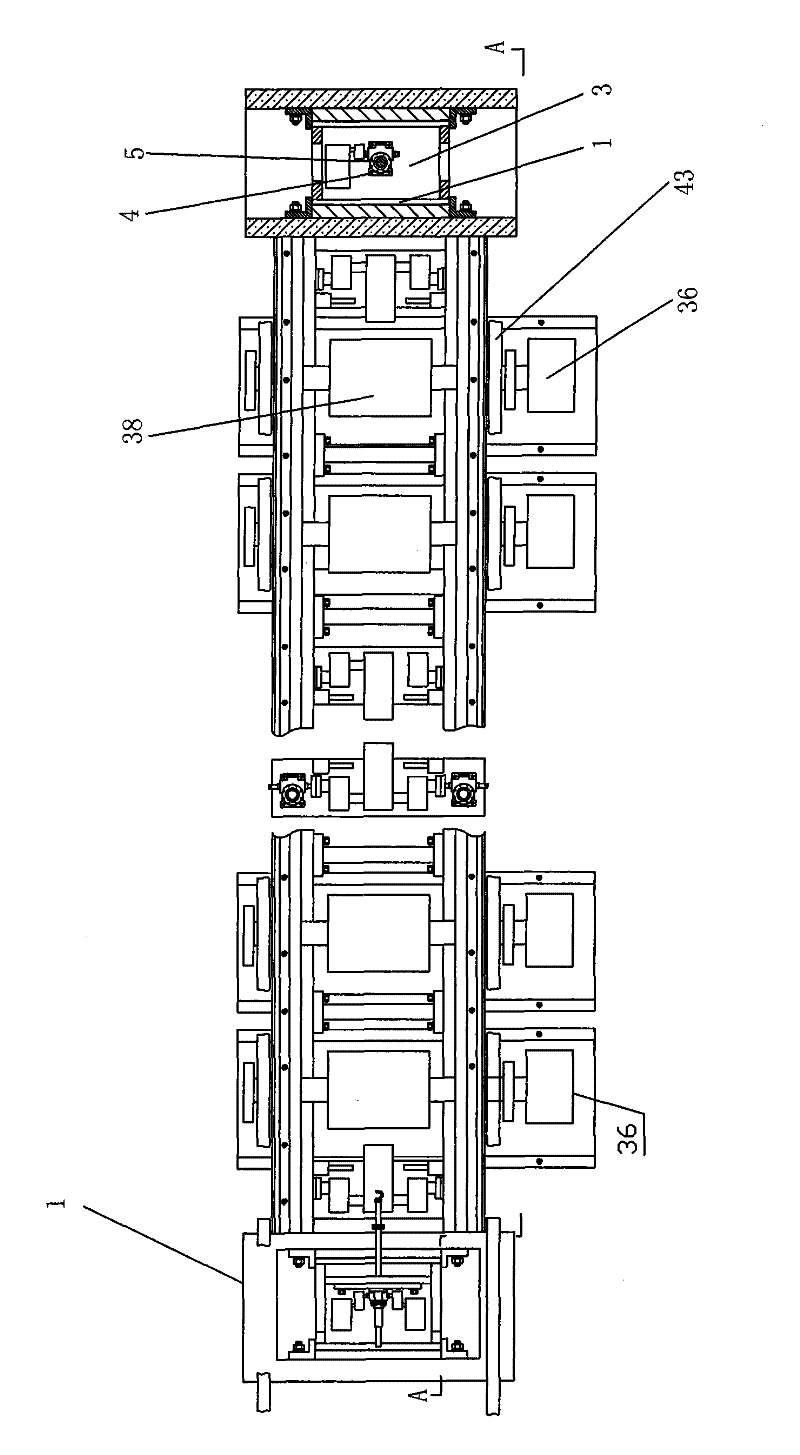

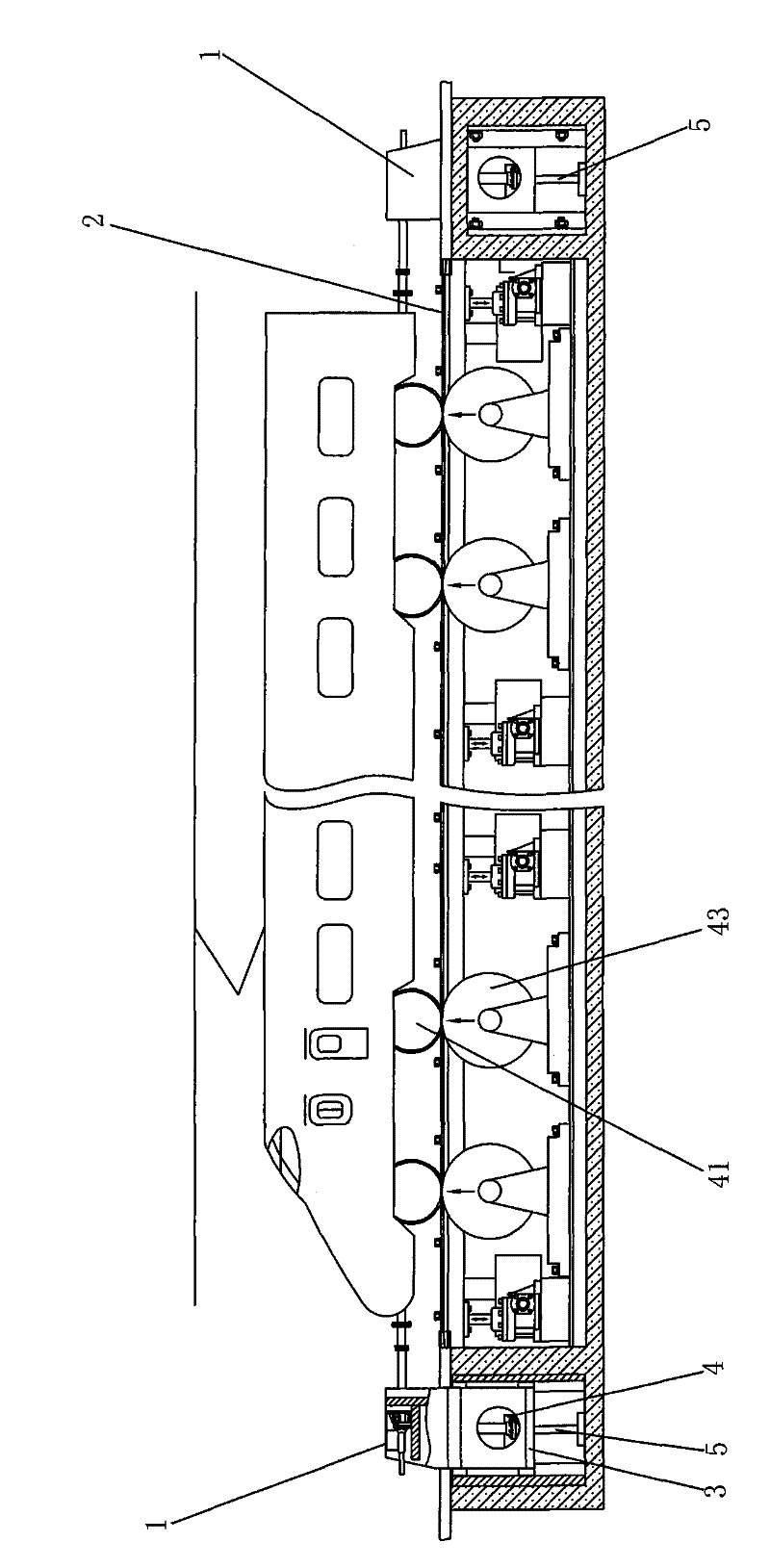

[0064] figure 1 , image 3 , Figure 7 As shown, a specific embodiment of the present invention is: a fixed rolling test bench for a single locomotive, including two reaction force frames 1 and an upper axle 2, and the same number of test units as the wheel pairs 41 of a single locomotive. The test unit group, wherein: the composition of the test unit is that the shaft of the rail wheel pair 43 supporting the locomotive wheel pair 41 is connected to the winding asynchronous motor 36 shafts; the diameter / length ratio of the winding asynchronous motor is greater than 1, and the rail wheel To the middle part of the axle of (43), flywheel (38) is also installed, and flywheel 38 shares bearing with track wheel pair 43.

[0065] Figure 7 It shows that the stator windings of the wound asynchronous motors 36 of each test unit in the test unit group are connected in parallel through the stator three-phase busbar 53, and the stator busbar 53 is connected with the power grid through ...

Embodiment 2

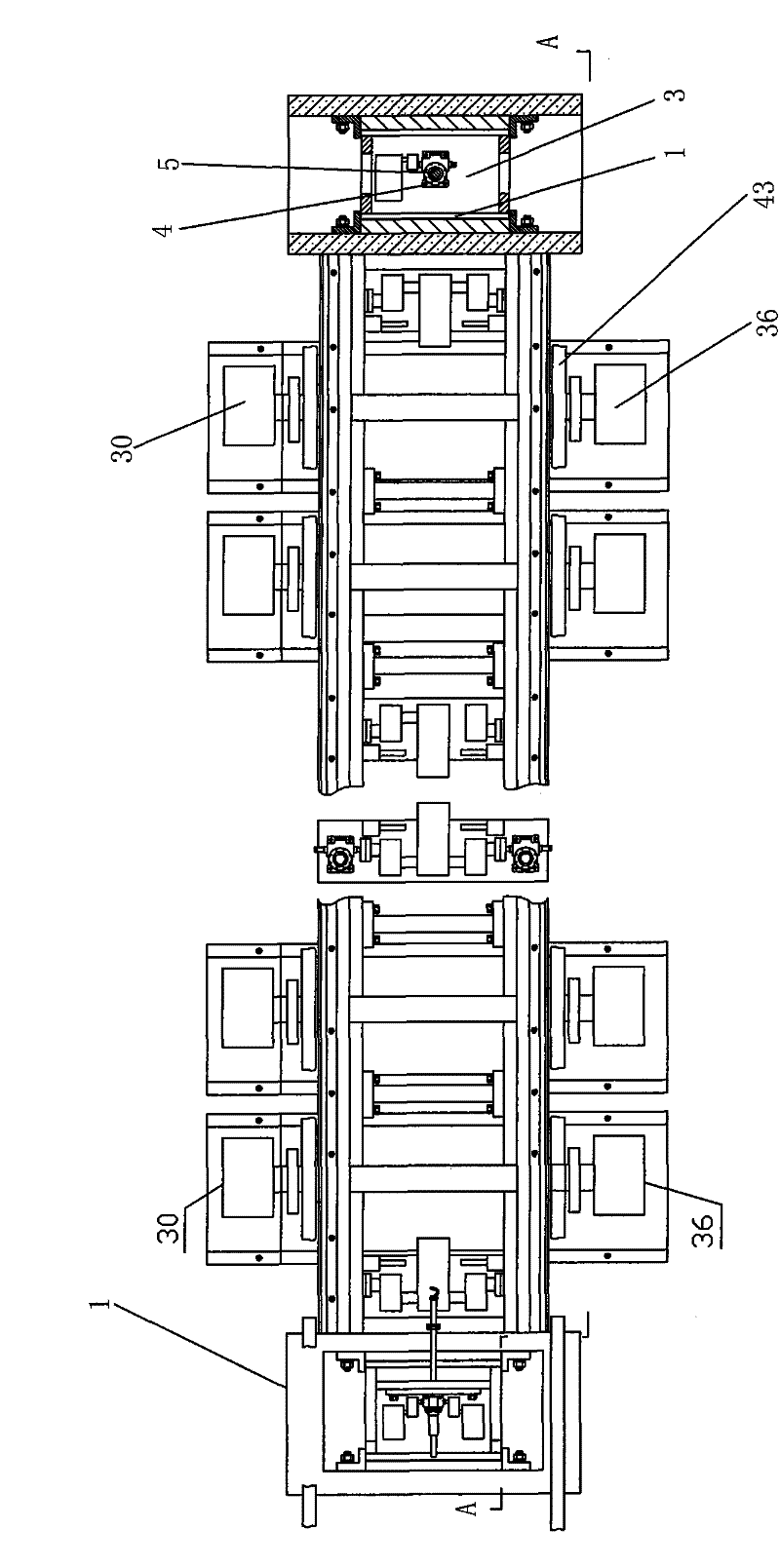

[0070] figure 2 , image 3 , Figure 5 , Image 6 , Figure 8 As shown, the structure of this example is basically the same as that of Embodiment 1, and the difference is that the shaft of the track wheel pair 43 is also connected with the shaft of the synchronous motor 30 at the same time, and the diameter / length ratio of the synchronous motor 30 is greater than 1; the track wheel pair 43 There is no flywheel installed.

[0071] In the test unit group, the electrical connection mode of the synchronous motor 30 of each test unit is: the stator winding of the synchronous motor 30 is connected to the synchronous motor stator three-phase busbar 61 in parallel; the synchronous motor stator three-phase busbar 61 is connected to the The three star-connected capacitors 2 77 are also connected to the three star-connected energy consumption resistors 2 75 through the switch 8 64 , and the rotor windings of the synchronous motor 30 are connected in series with each other, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com