Method for predicting atmospheric corrosion rate of metal material

A metal material and atmospheric corrosion technology, applied in the fields of weather resistance/light resistance/corrosion resistance, analytical materials, measuring devices, etc., can solve difficult corrosion prediction research and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

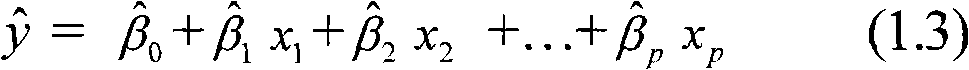

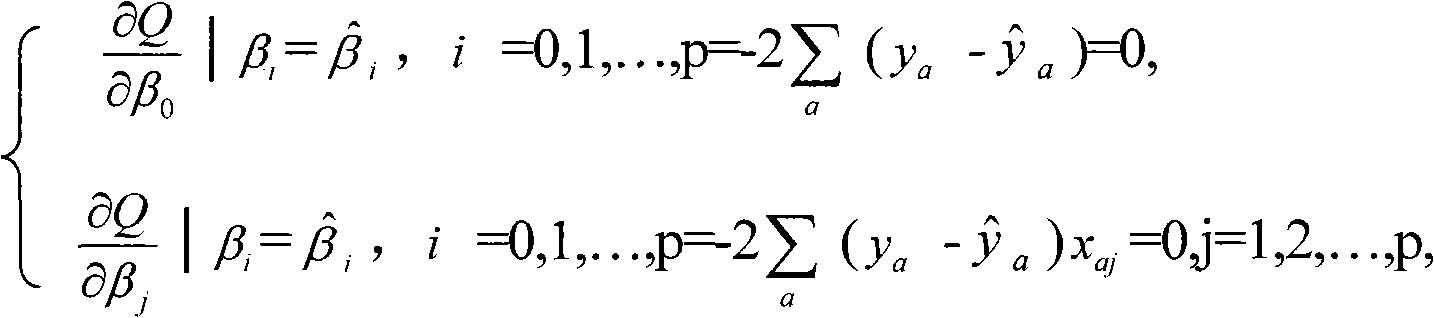

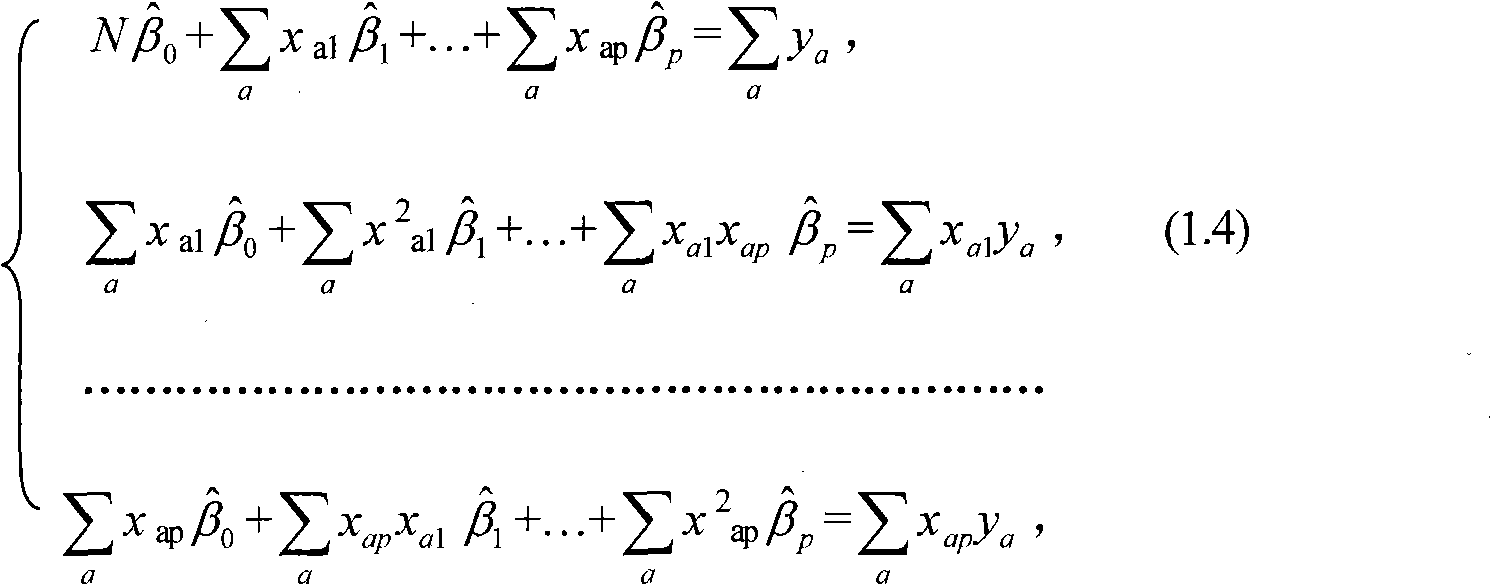

Method used

Image

Examples

Embodiment 1

[0055]From June 1990 to May 1992, a 2-year survey of atmospheric corrosion was carried out in Hainan. There are test points in 20 cities and counties, basically evenly distributed. The test material is Q235 steel, and the sample size is 100mm×50mm×3mm. The chemical composition of Q235 steel is shown in Table 1. The sample is processed to smoothness by milling machine and grinding machine or above, remove oil with acetone, dehydrate with ethanol, place in a desiccator for 24 hours, and weigh with an analytical balance with a sensitivity of 0.1 mg.

[0056] Table 1, A 3 Chemical composition of steel (wt%)

[0057] C

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com