System and method for inspecting a wafer

A detection system and wafer technology, which is applied to TV system parts, measurement devices, optical test flaws/defects, etc., can solve the problem that the semiconductor wafer detection system cannot use bright field and dark field imaging at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 400

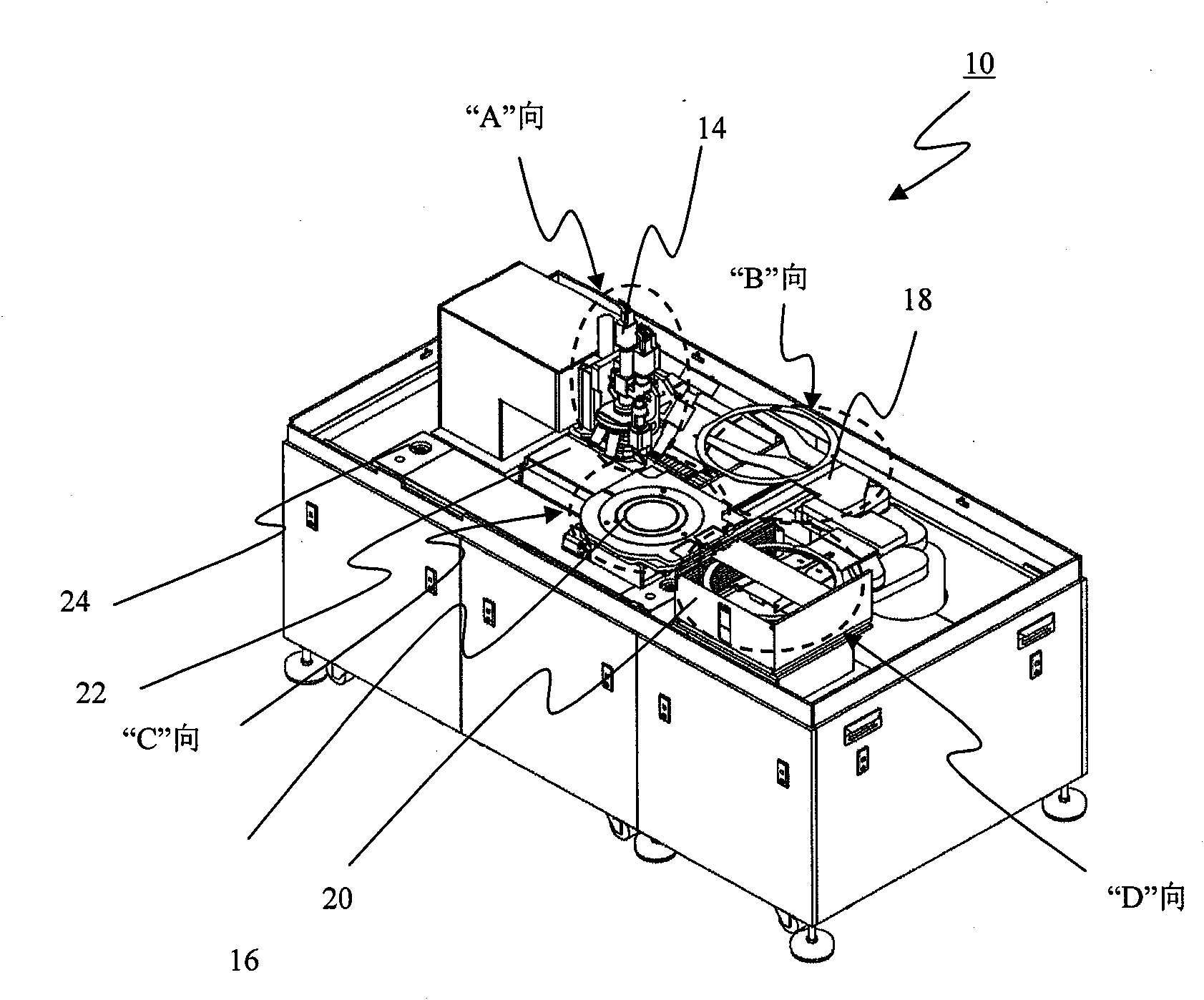

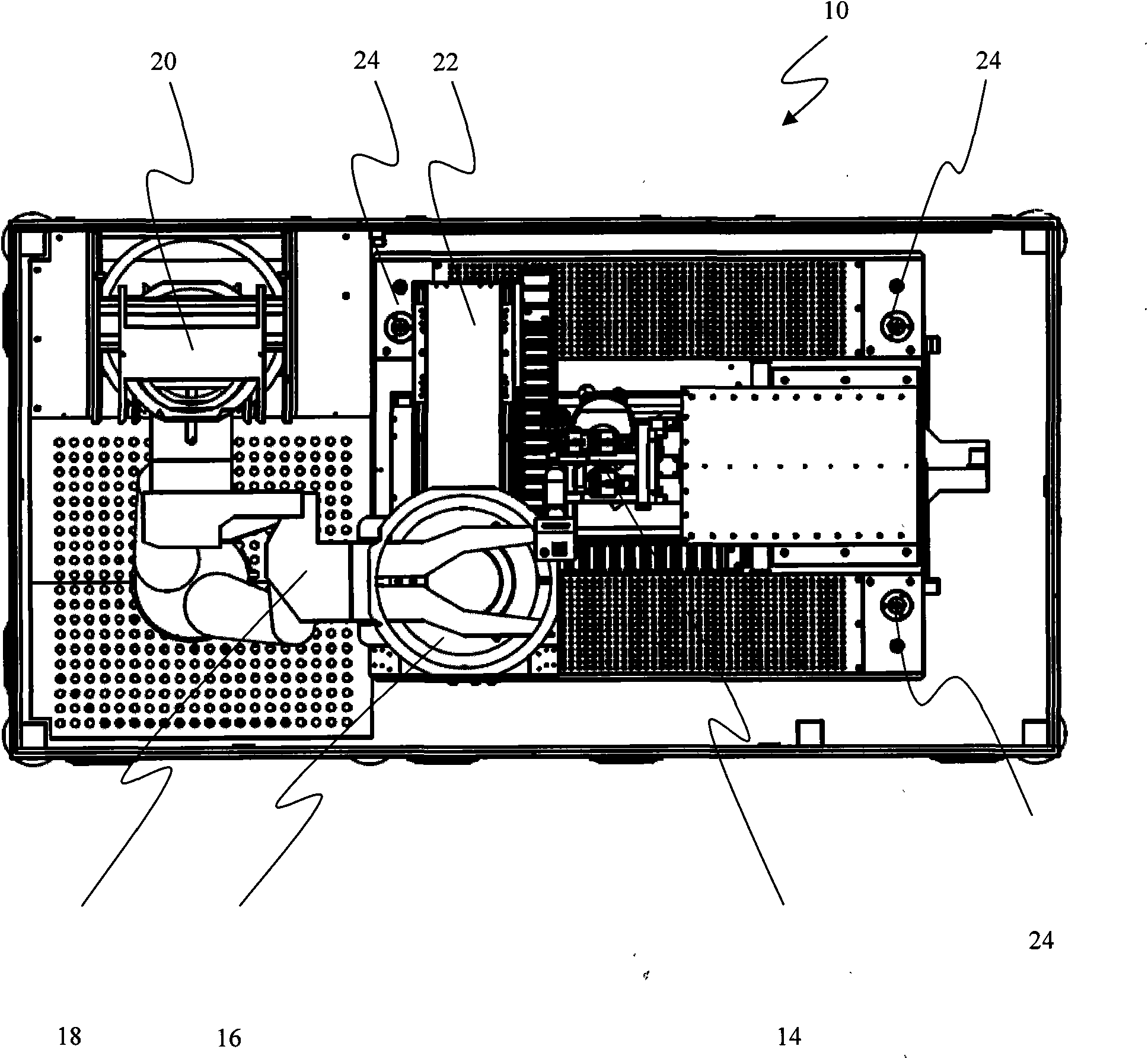

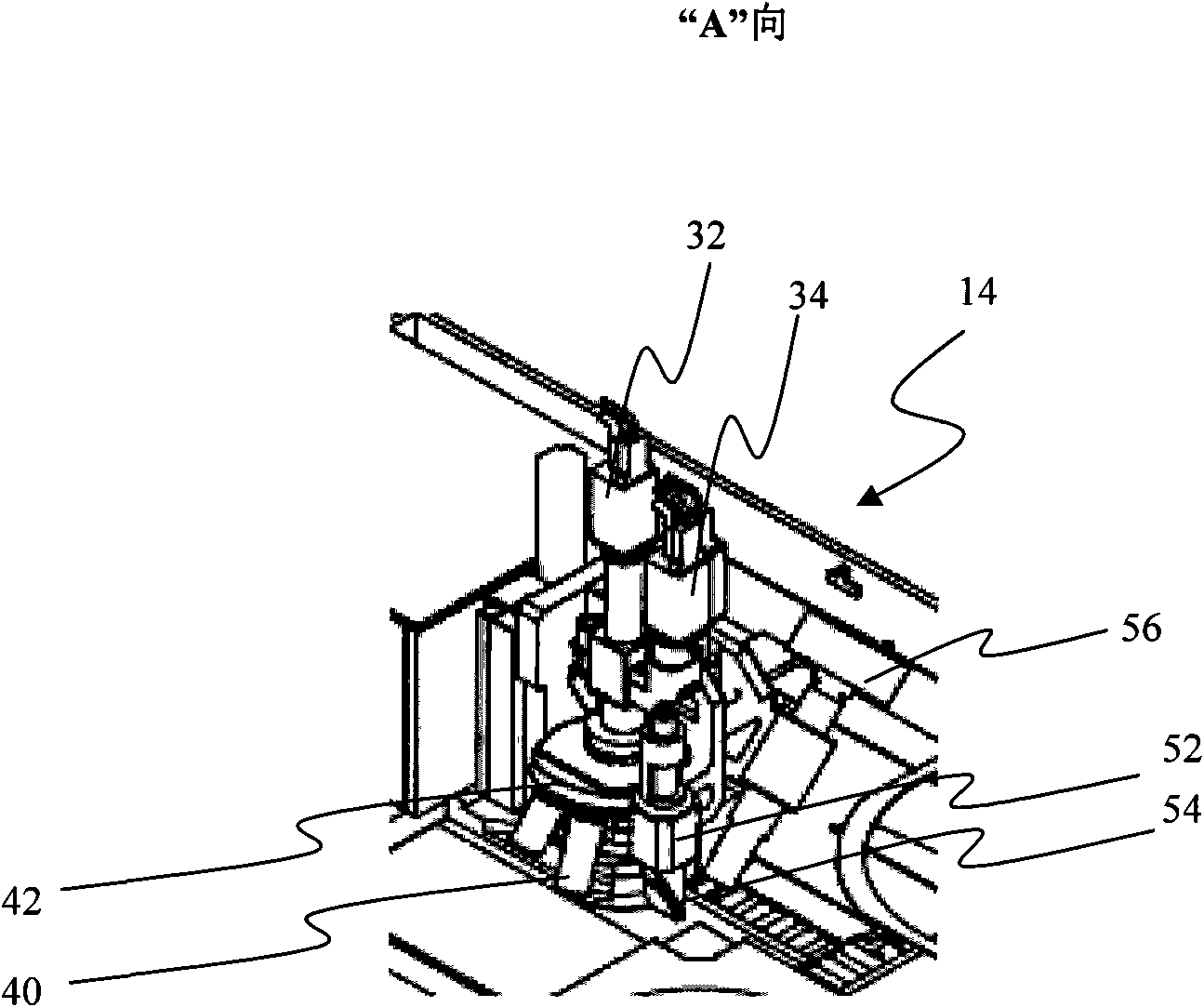

[0181] As mentioned above, the present invention provides an implementation method 400 for inspecting the semiconductor wafer 12, thereby performing at least one of defect detection, classification and review on the semiconductor wafer.

[0182] In step 402 of method 400, semiconductor wafer 12 is loaded onto wafer table 16 by system 10 for inspection, and semiconductor wafer 12 is removed from semiconductor stack 20 and transferred to wafer table 16, preferably by robotic wafer handler 18. . Suction or vacuum is applied to the wafer table 16 to secure the semiconductor wafer on the wafer 12 table.

[0183] Semiconductor wafer 12 preferably contains a wafer identification number or barcode. The above-mentioned wafer identification number or barcode is written or marked on the surface of the semiconductor wafer 12 , specifically at the edge of the surface of the semiconductor wafer 12 . The wafer identification number or barcode is used to identify the semiconductor wafer 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com