Peristaltic hose pump

A technology of roller pumps and hoses, applied in the direction of pumps, pump control, pump parameters, etc., can solve the problems of less convenient user operation, no timely injury, pump failure, etc., to avoid the risk of injury, reliable operation, high reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

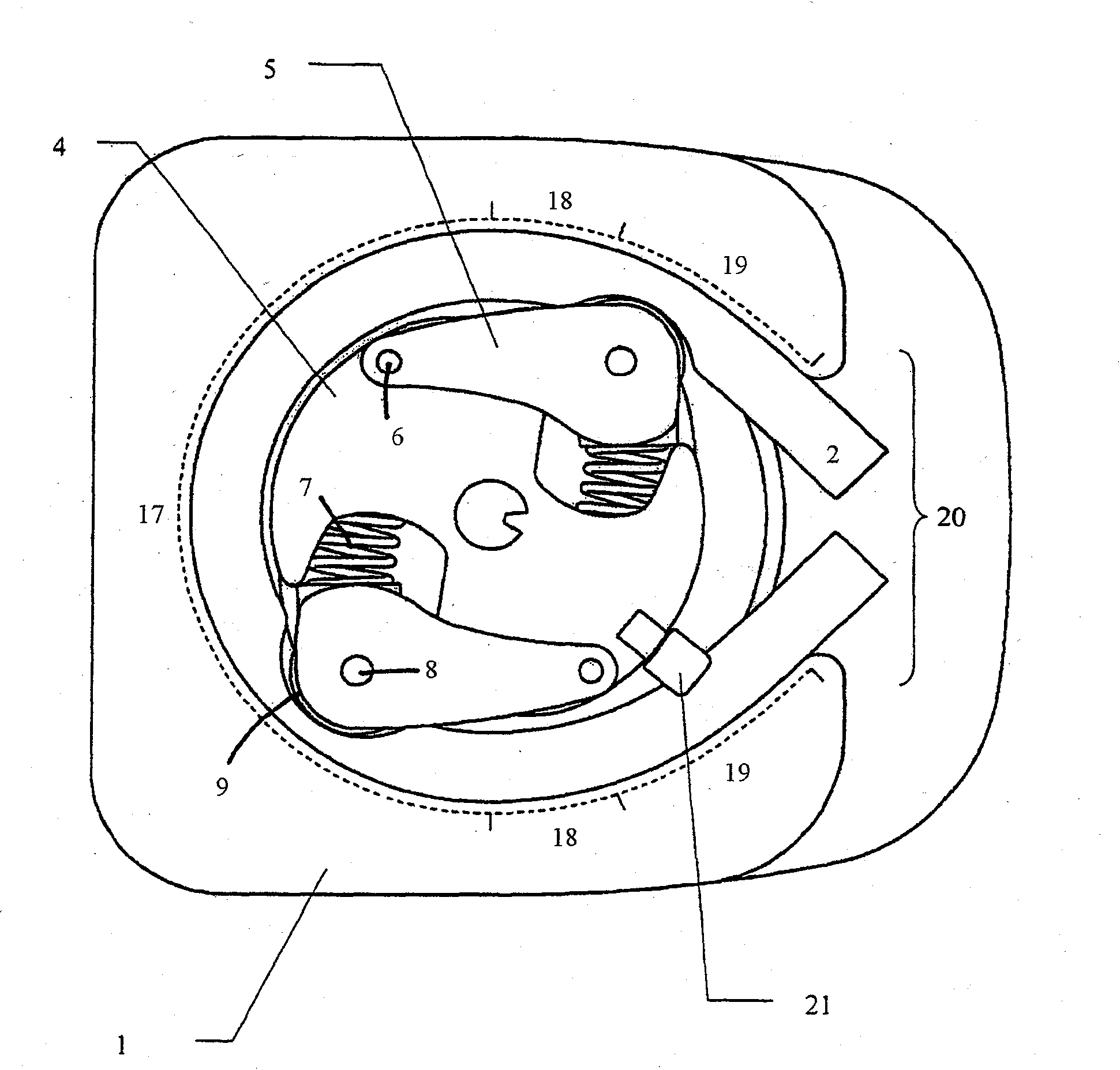

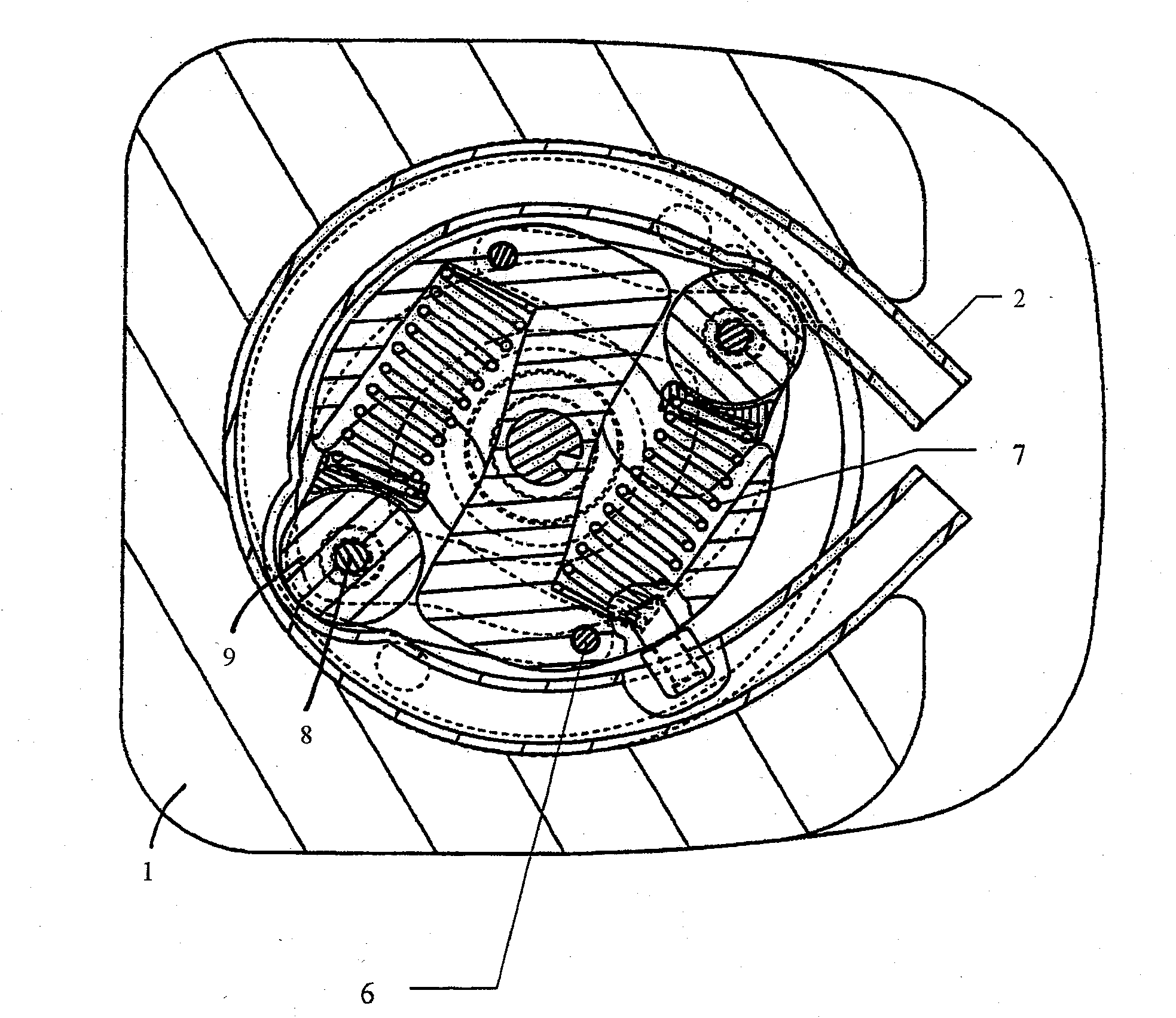

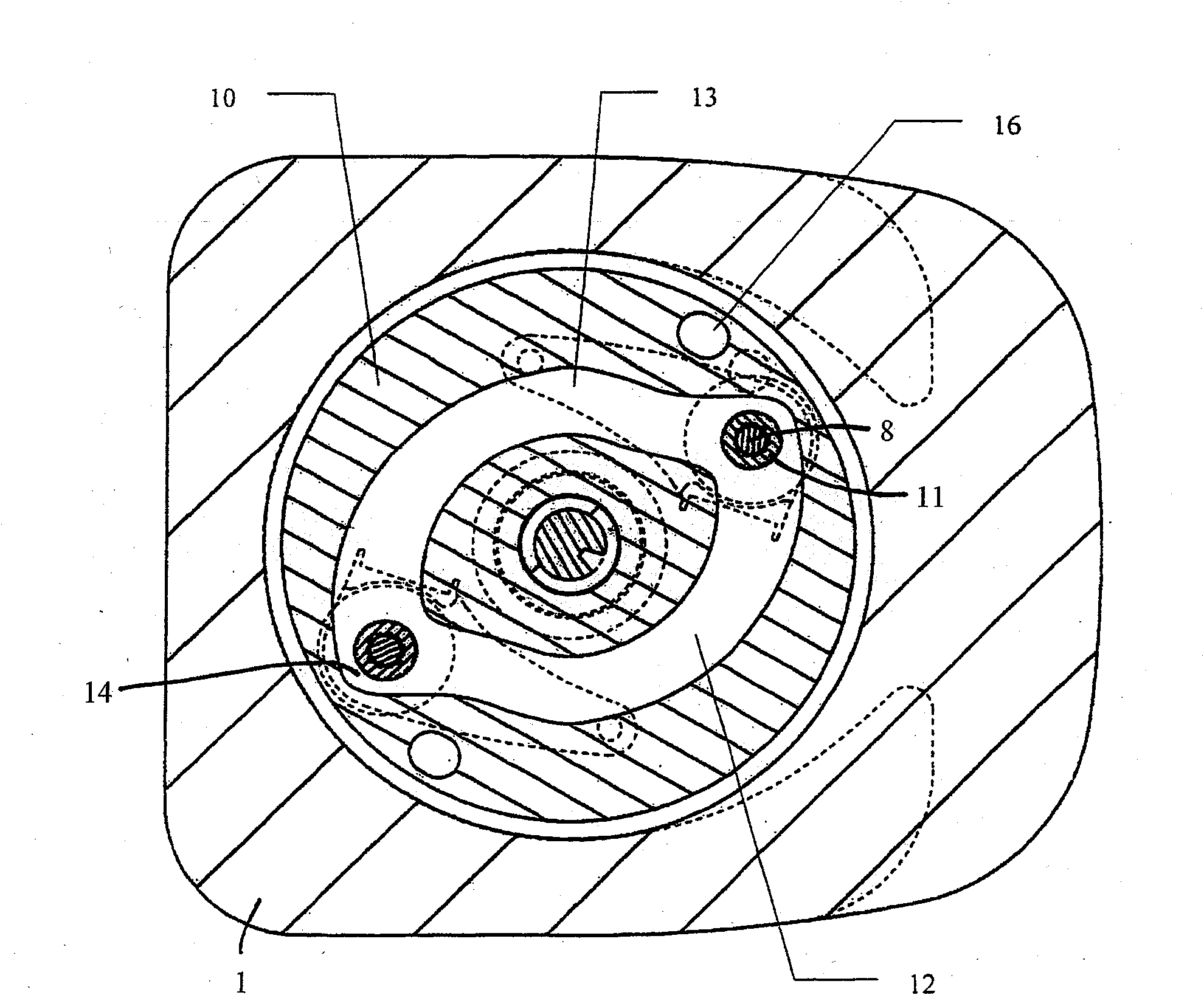

[0052] The general structure of the exemplary embodiments of the invention is based on the proven basic types already described at the outset, so that reference is made to the descriptions of the prior art with regard to the basic structure and pump function of the invention. about in figure 1 With respect to the elements that can be seen in , the invention differs from the prior art only by the shorter and more rounded hose guide wings 21 . In addition, however, the invention is identical to the hose roller pump according to the prior art with respect to the basic elements of the rotor and the stator. Therefore, the embodiments of the invention also have the same advantageous features of the hose roller pump which have been proven for a long time when the pump is running, but it is now possible to significantly improve the Simplifies hose insertion and removal.

[0053] Here, the rotor of the exemplary embodiment of the hose roller pump according to the invention is based ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com