Valve element and thermostatic control device for controlling a mass flow

A technology of constant temperature adjustment and quality adjustment, applied in the field of valve components, it can solve problems such as limitation, and achieve the effect of simple and fast matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

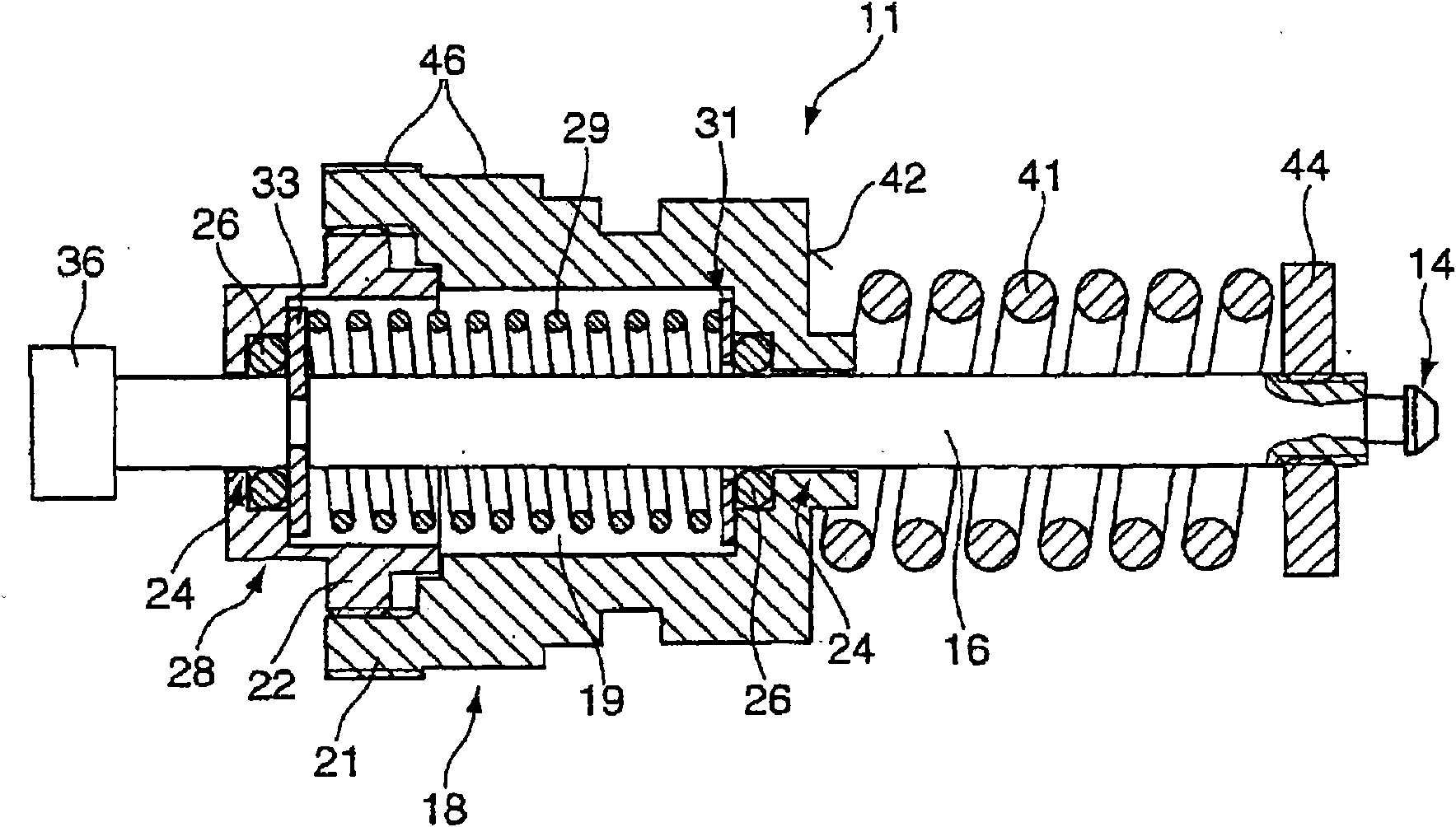

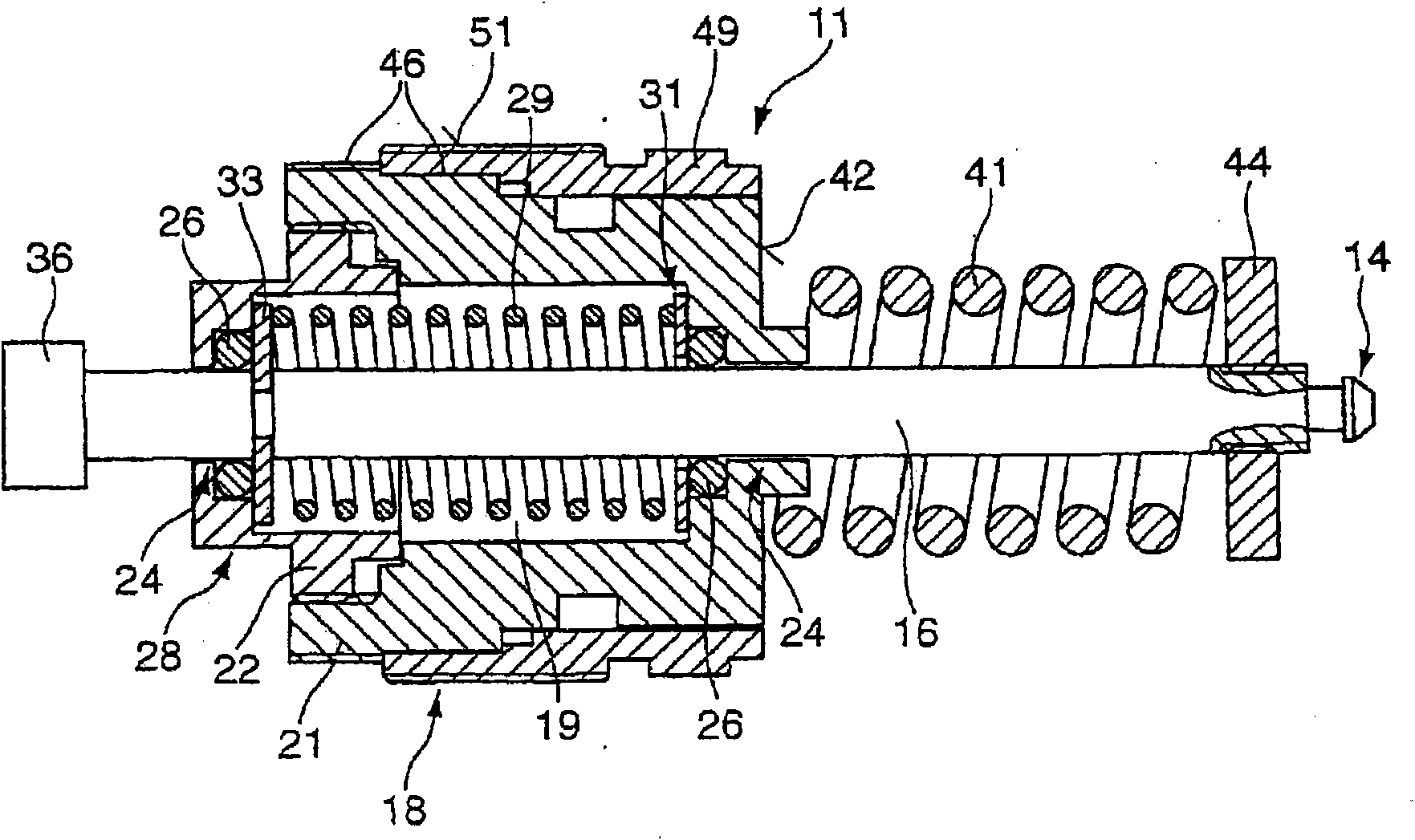

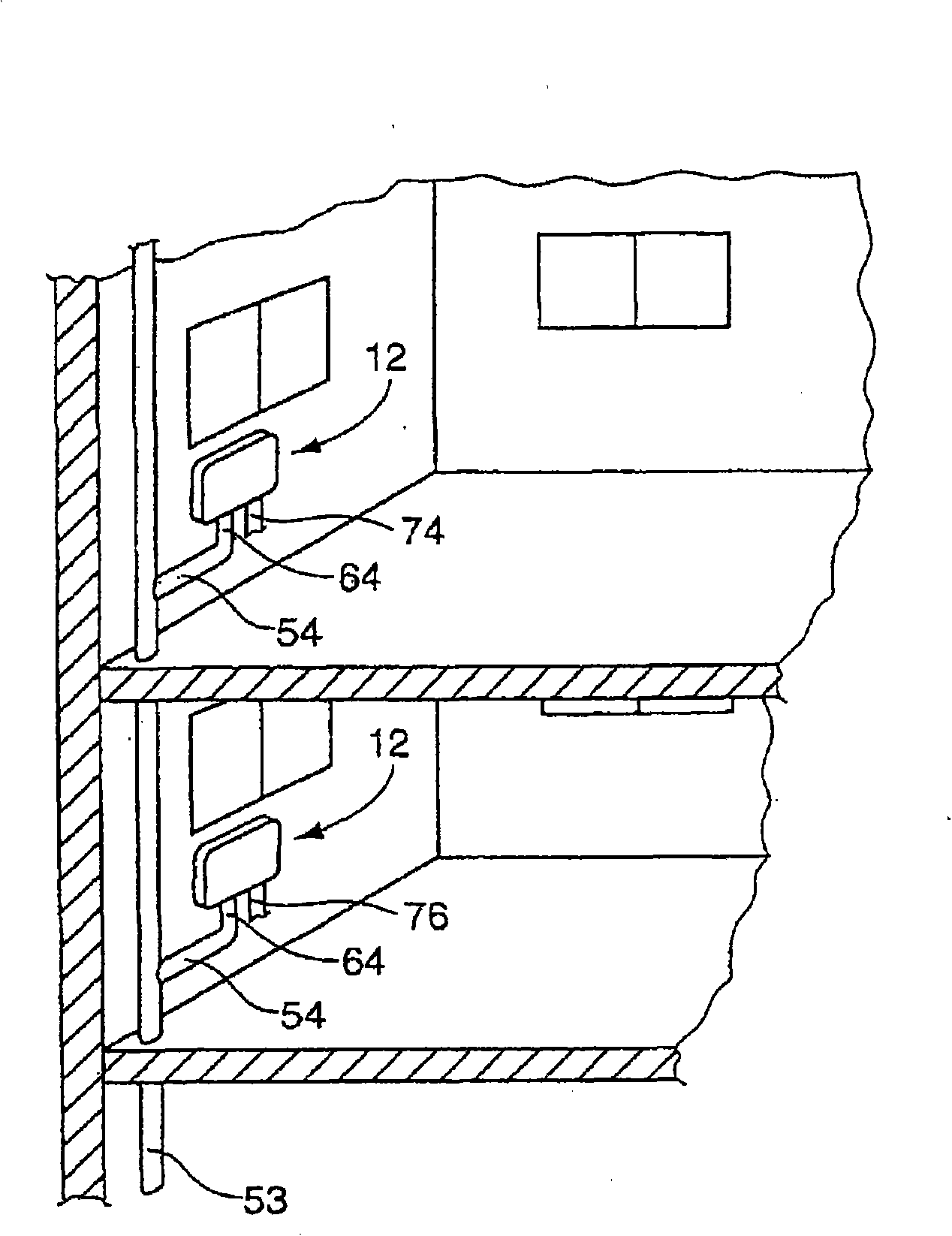

[0037] figure 1 A schematic cross-sectional view of the valve element 11 is shown in. This valve element 11 is preferably configured as a built-in cylinder and is set to be used in a thermostat 12, in image 3 The installation location of the thermostat 12 is shown and described in detail in Figure 4a to 4c The structure of the thermostat 12 is shown and described in detail.

[0038] The valve element 11 includes a valve closing member 14 which is movable relative to a valve seat in the thermostat 12 in order to adjust the mass flow. The valve closing member 14 includes, for example, a transfer pin 16 which is guided through the housing part 18 in an axially movable manner. Preferably, the transfer pin 16 passes through the cavity 19 in the housing part 18 and leads from the housing part 18 on the opposite side. The housing part 18 has a first part 21 preferably configured in a U-shape, and a second part 22, which are fixed to each other by a separable connection, in particula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com