Labor-saving flue-cured tobacco cultivation method

A cultivation method and flue-cured tobacco technology are applied in the fields of botanical equipment and methods, equipment for eliminating weeds, gardening, etc., which can solve problems such as insignificant effects, achieve the effects of not reducing the yield and quality of tobacco leaves, reducing production costs, and being easy to popularize.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

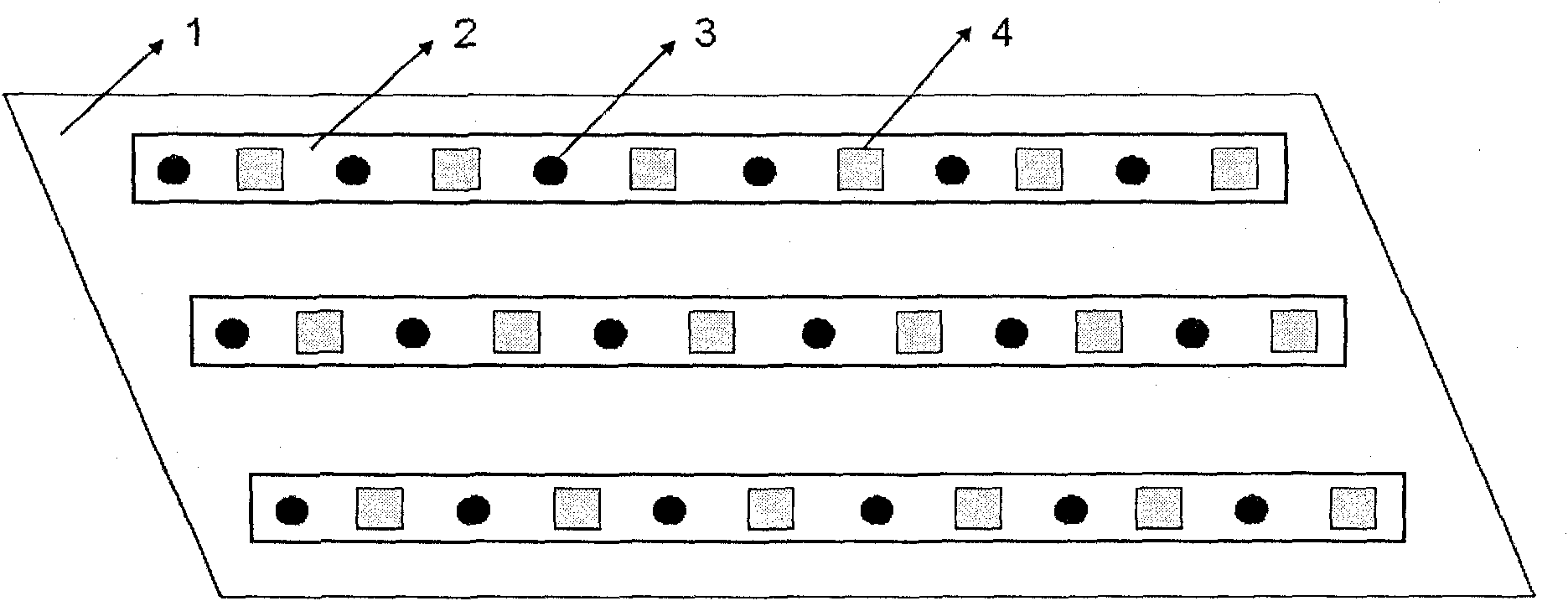

[0017] As shown in the figure, in the tobacco field after the flue-cured tobacco is harvested, cut the tobacco stem from the rhizome close to the ridge body and clean the tobacco field, leaving the tobacco stubble in the ridge body to protect the ridge body; From the beginning of the spring to the tobacco planting in the following year, apply a 50% napropamide WP herbicide, every 667m 2 Apply 150g to control the growth of weeds. When planting tobacco, place a large nest in the middle of the two tobacco stubble residues in the ridge, and apply the nitrogen, phosphorus and potassium ratio of 1:1.5:2.5 tobacco special compound fertilizer, every 667m 2 Apply 6.5kg of pure nitrogen, apply fertilizer to the large nest at one time, and then select strong seedlings to deep plant at the same depth as the height of the tobacco seedling stalks, pour fixed root water after transplanting, pay attention to the prevention and control of underground pests, and check the seedlings in time Repleni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com