Food cutting machine capable of cutting food into uniform particles

A technology of particle uniformity and pelletizer, applied in metal processing and other directions, can solve the problems of manual knife cutting, such as high labor intensity and uniform particle thickness, and achieve the effect of simple and reasonable structure and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

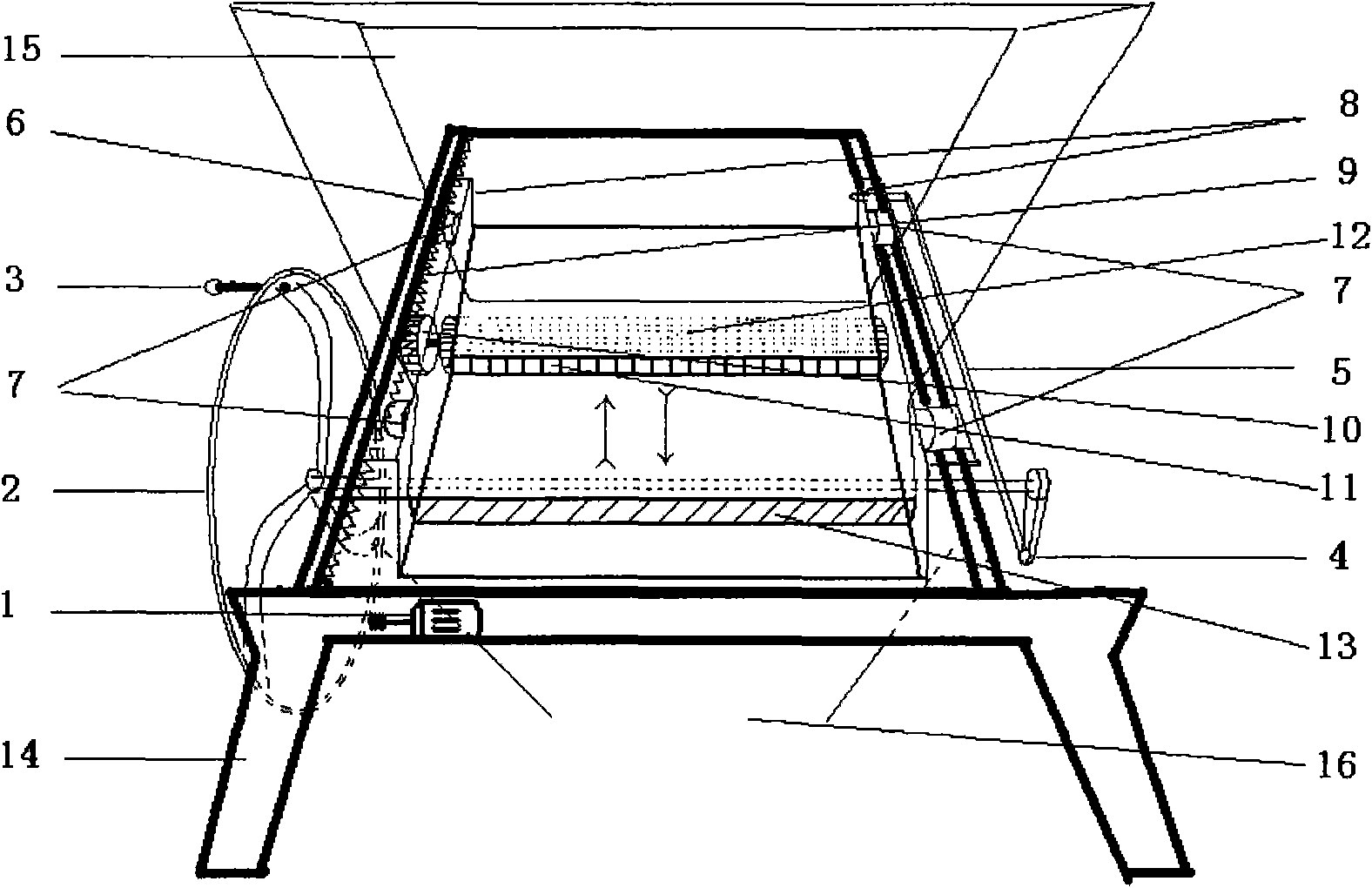

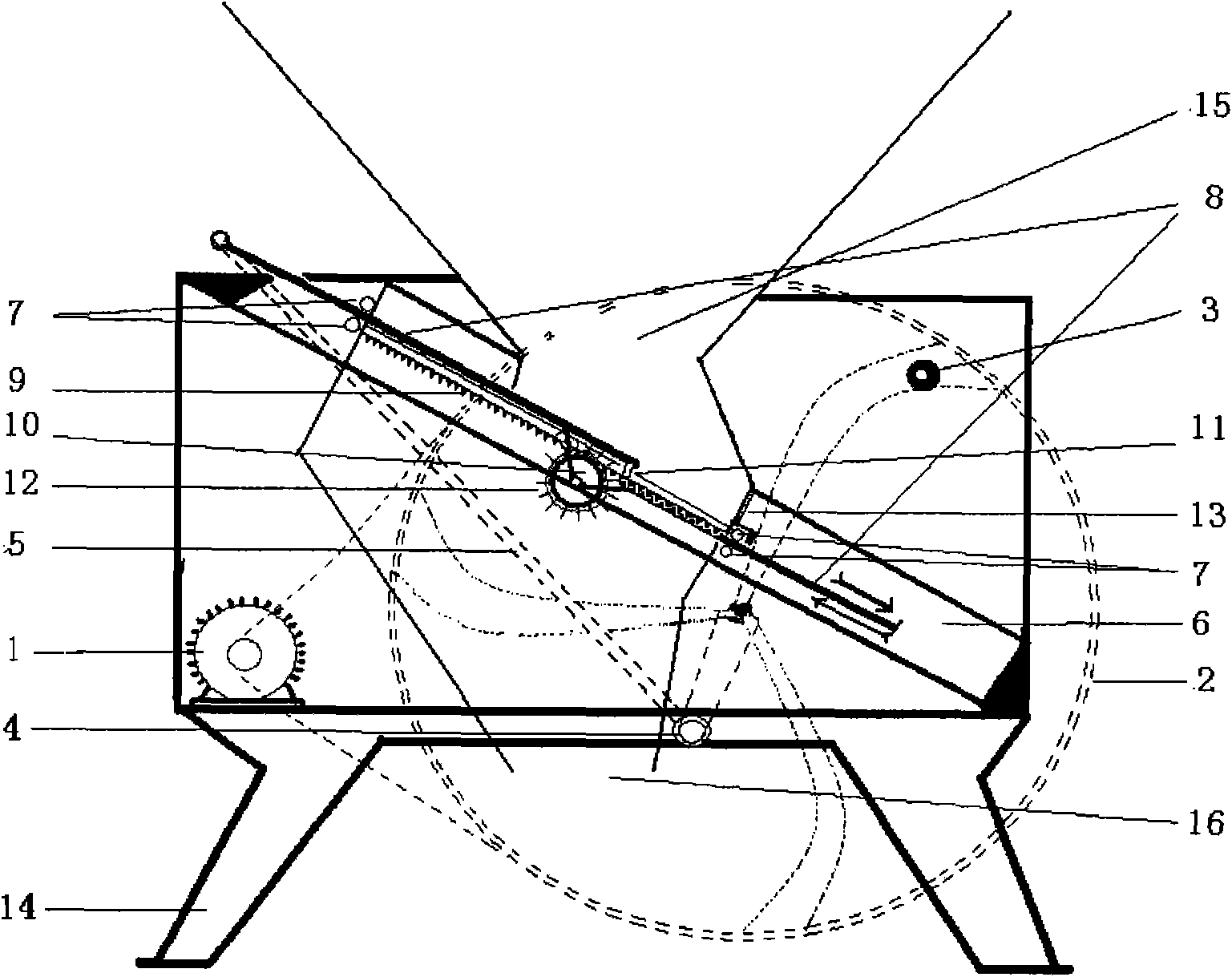

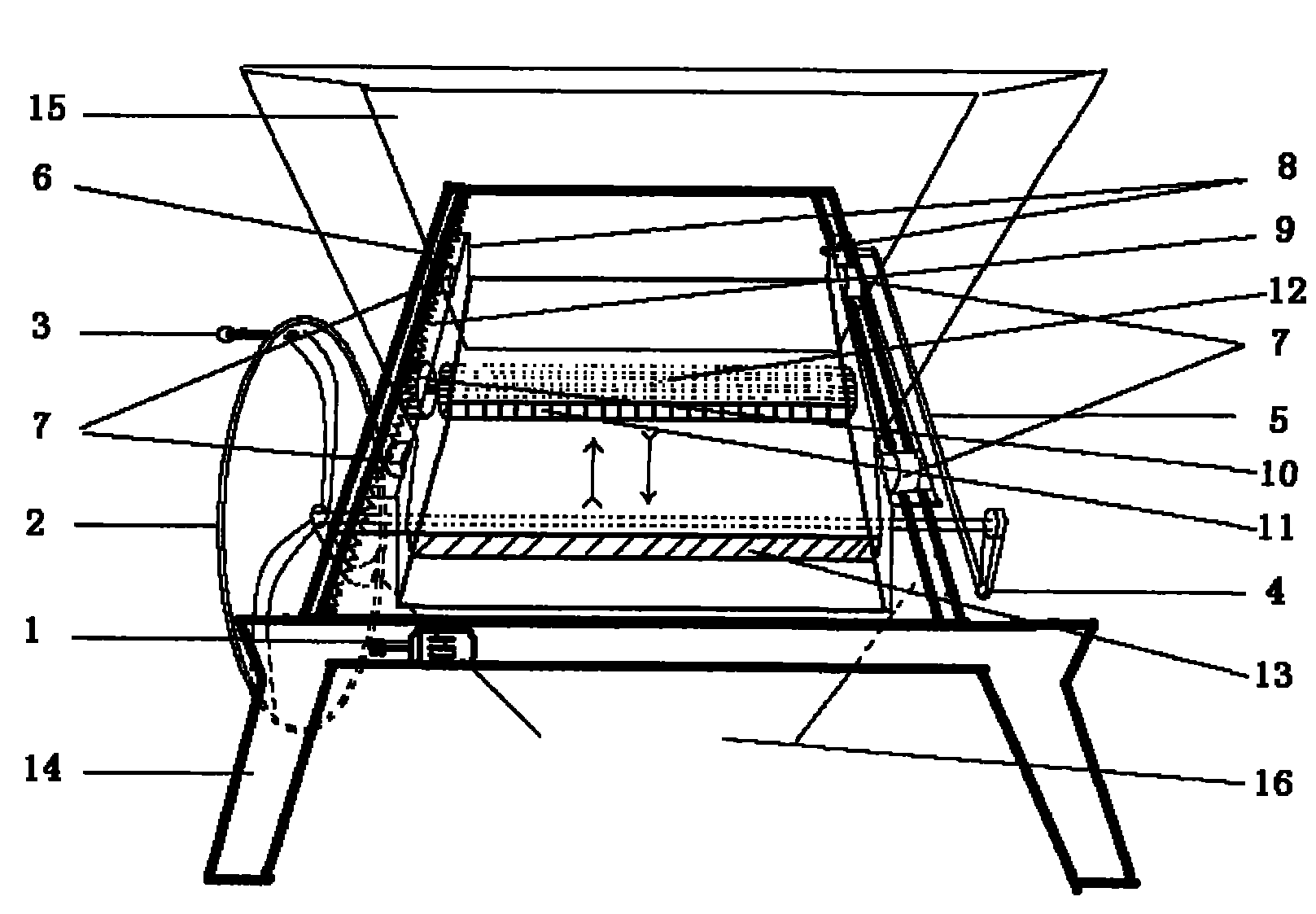

[0009] See figure 1 , figure 2 , food granulator, has a base 14, on the base 14 there is a motor 1, a belt flywheel 2, a hand handle 3, a rocker arm 4, a connecting rod 5, a fixed frame 6, a movable knife rest bearing 7, a movable knife rest 8, teeth Bar 9, gear 10, vertical combination knife 11, horizontal rotating wheel steel sheet combination knife (or steel wire combination knife 12), vertical combination knife terminates cutting board 13, feed port 15, discharge port 16, when the motor 1 rotates, it is driven by the belt Or hand handle 3 shakes flywheel 2, shakes 4 rotations by flywheel shaft, drives the live knife rest 8 in the movable knife rest bearing 7 above the fixed mount 6 through connecting rod 5. Reciprocate back and forth diagonally forward and downward. The food of feeding port 15 is under the effect of own weight, and under the more narrower extruding of forward inclined lower feeding port, forces food to be close to the vertical combination knife 11 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com