Tension-driving automatic wire-arranging mechanism

An automatic wiring and wire technology, which is applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of high labor intensity of workers, increase in the number of equipment sets, and high cost of equipment, so as to achieve low labor intensity of workers , Stable cable quality and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment, the present invention will be described in further detail:

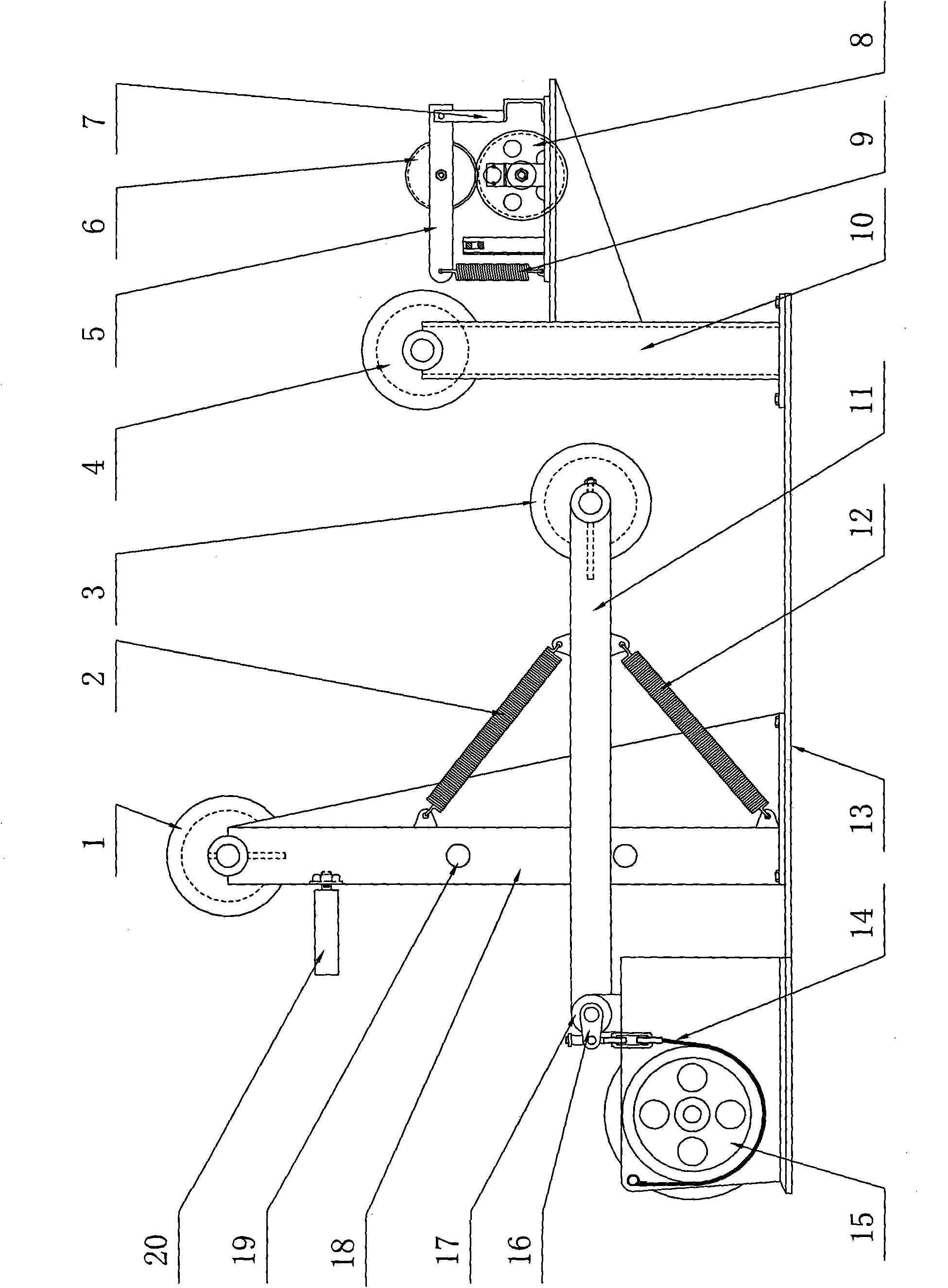

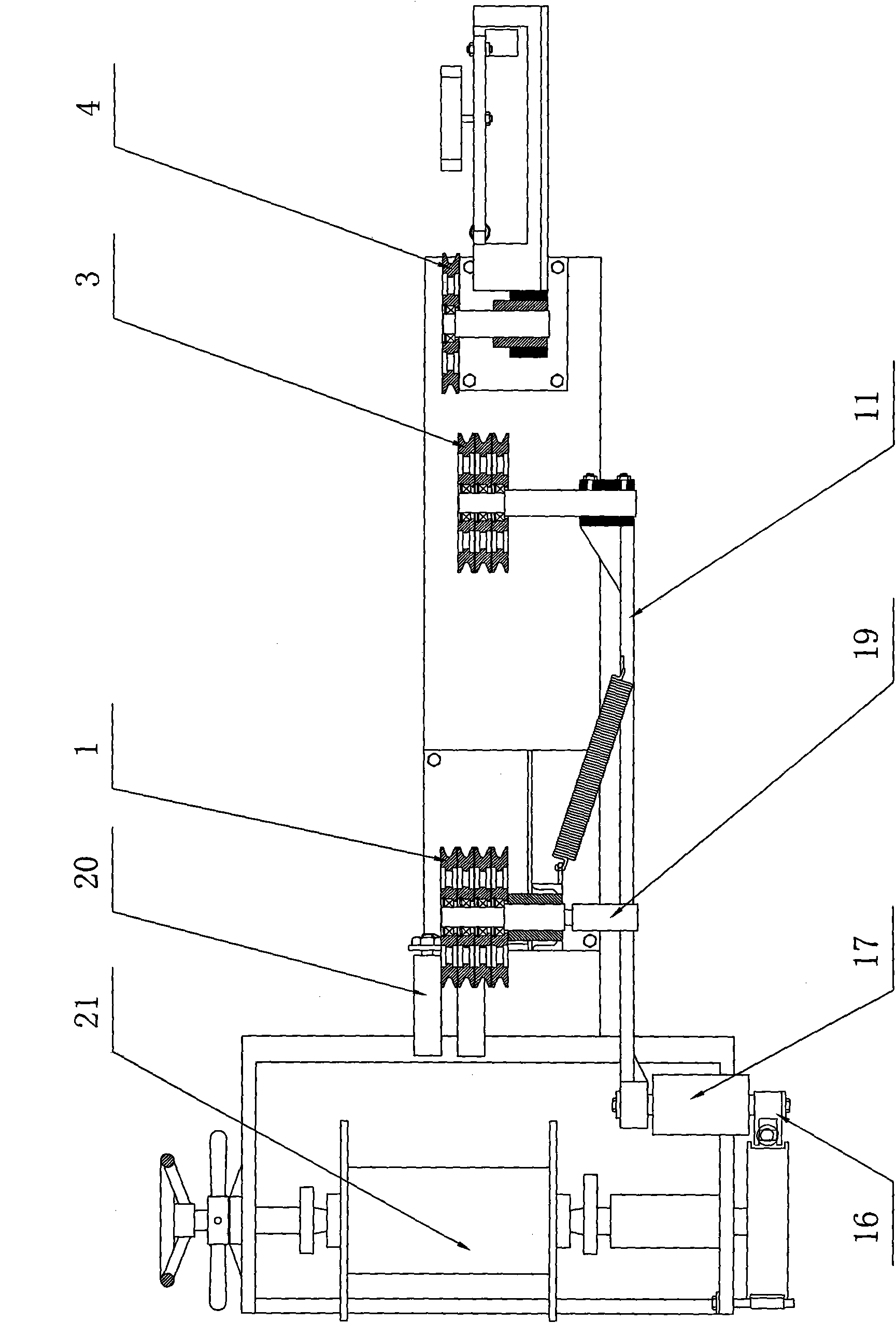

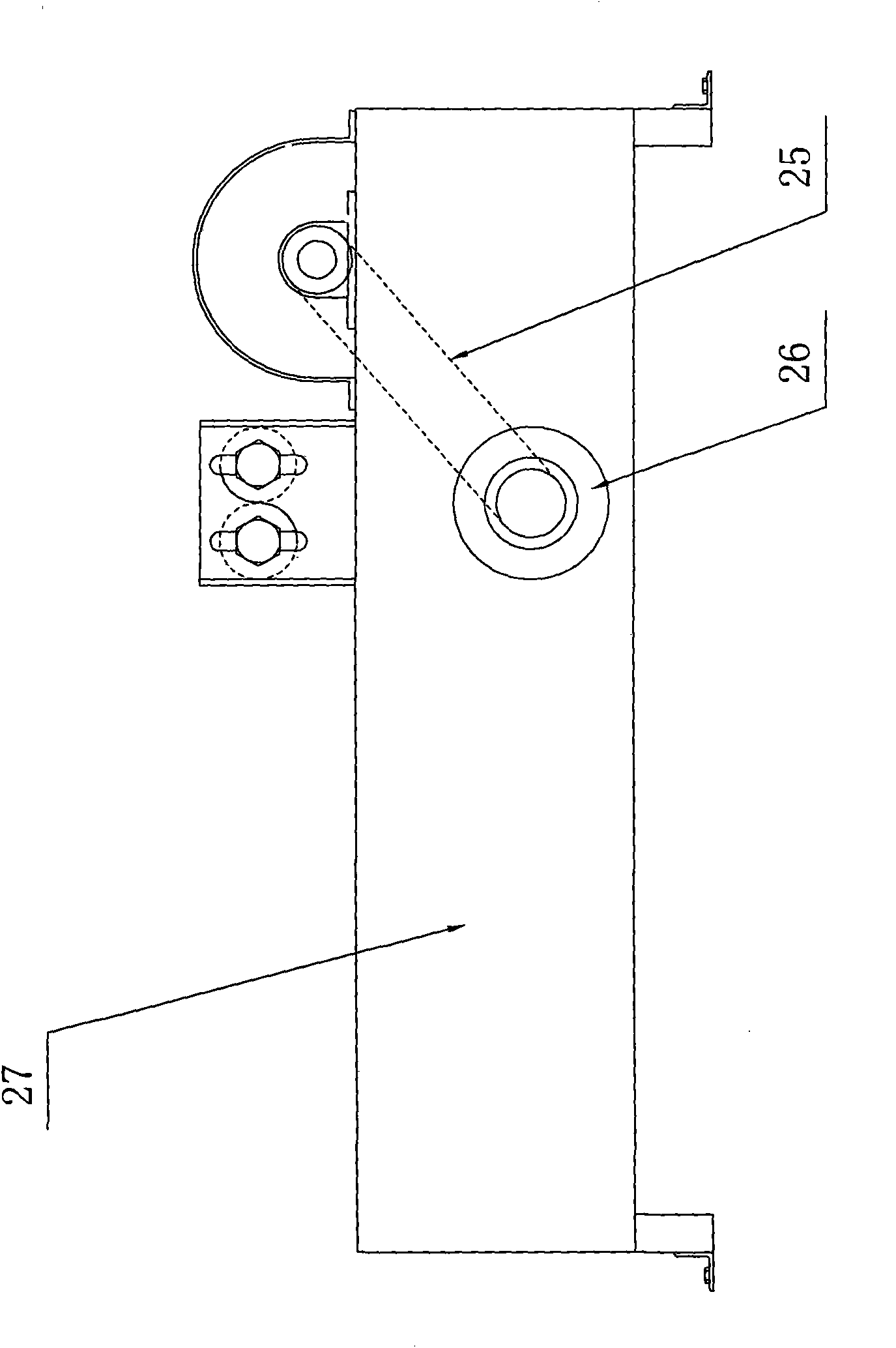

[0018] like Figures 1 to 4 As shown, it is a tension-driven wire automatic arranging mechanism, including a pay-off device and a loop-forming device, wherein the pay-off device includes a base 13, a floating guide wheel group 3, a pay-off frame 21, The fixed guide wheel group bracket 18 and the guide wheel bracket 10, the fixed guide wheel group 1 arranged on the fixed guide wheel group bracket, and the guide wheel 3 arranged on the guide wheel bracket; The motor 26 on the electric box, the ring-forming disc 24 driven by the motor; the fixed guide wheel group 1 is composed of four guide wheels connected in series coaxially, and the four guide wheels can rotate freely; the floating guide wheel group 3 is composed of the same The shaft is composed of three guide wheels connected in series, and the three guide wheels can rotate freely. The feature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com