Spliced anti-static PVC coiled material, method and equipment for manufacturing PVC coiled material

An anti-static, PVC resin technology, applied in applications, flat products, household appliances, etc., can solve the problems of difficult quality assurance, time-consuming construction, and many seams, and achieve the effect of low product cost, low cost, and small workshop area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the following, the PVC coiled material of the present invention; the process for manufacturing the coiled material; and the complete set of equipment for realizing the process will be described in detail.

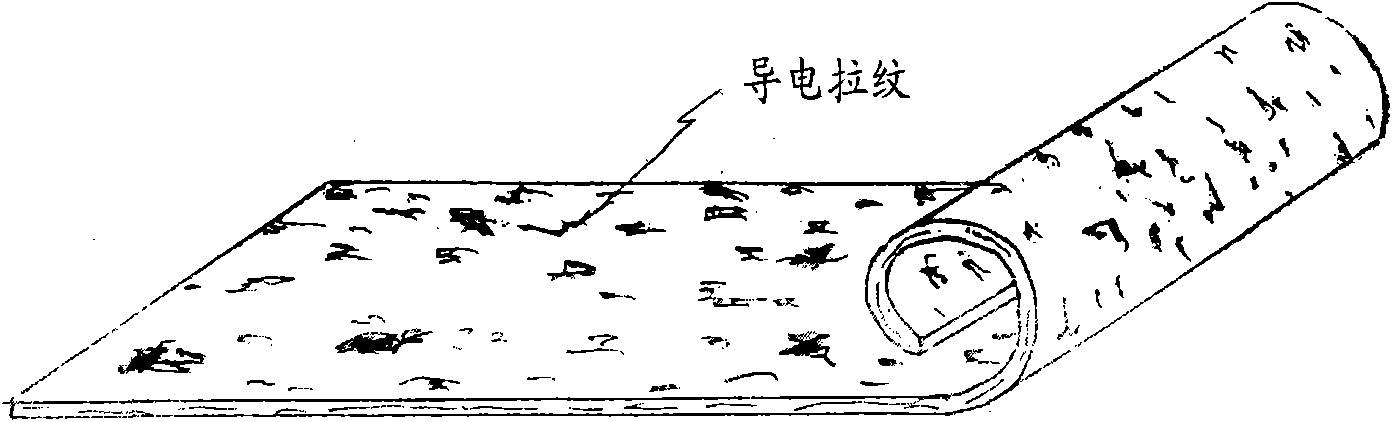

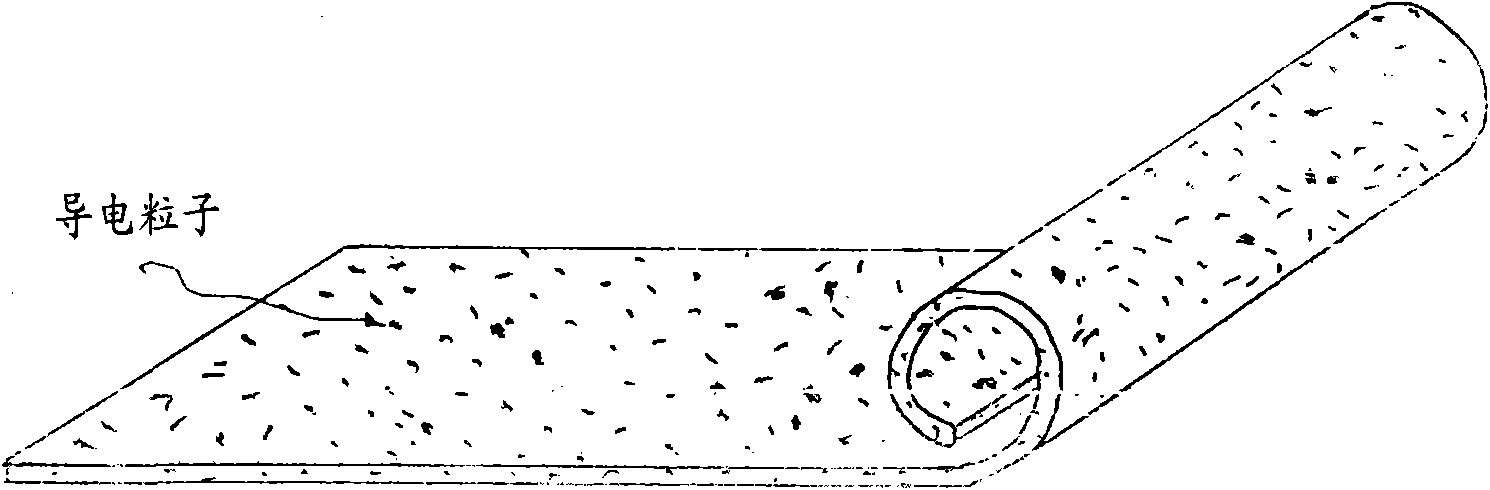

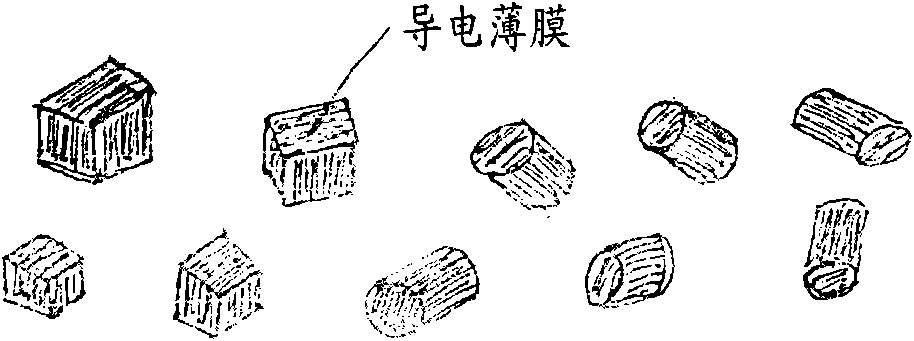

[0029] Figure 5Represents an antistatic PVC coiled material with uniformly distributed conductive wire mesh inside of the present invention. This coil is made of PVC resin, fillers, plasticizers, stabilizers, pigments, etc. After heating, stirring, and banburying, the conductive paste is wrapped on the surface of the pellets, and then dried to form a thinner thickness. Thick PVC panels. Then, it is cut into many PVC plates with a thickness equal to the thickness of the coil along the thickness direction on a layering machine. Then, after the cut PVC plates are polished on the polishing machine, on the splicing machine, these cut PVC blocks are spliced into PVC coils longitudinally and (or) transversely. The coiled material made through such a process has a u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com