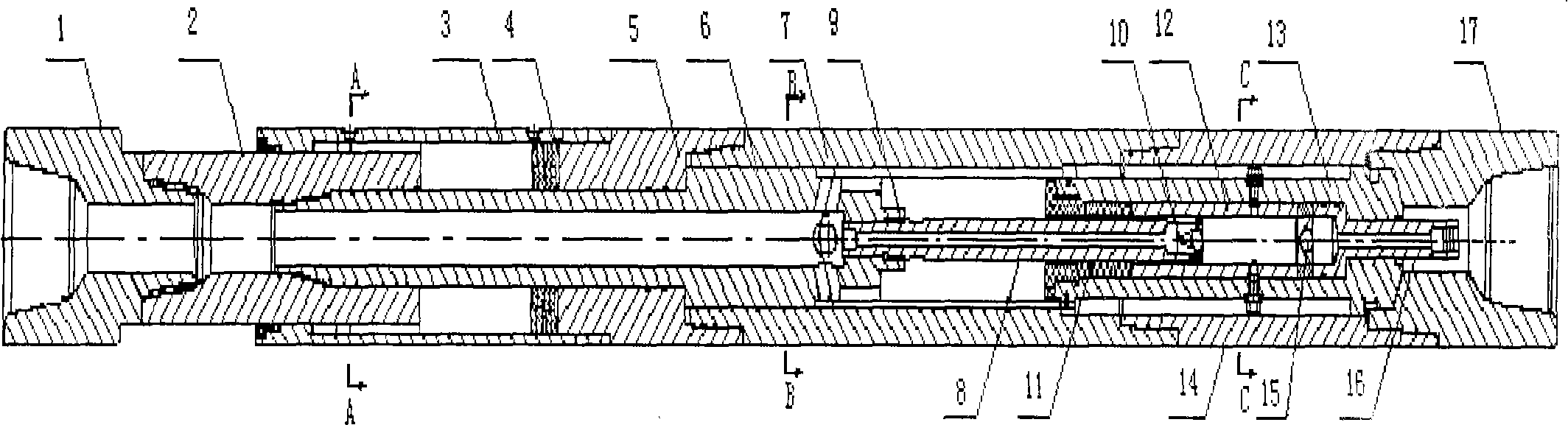

Underground drill stem vibration damping and pressurizing device

A booster device and drill string technology, which is applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of high cost, fatigue damage of drill string, etc., and achieve the effect of simple structure, satisfactory working life and improved rock breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

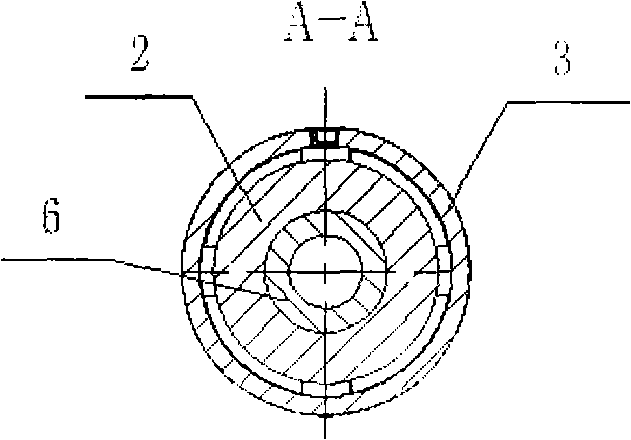

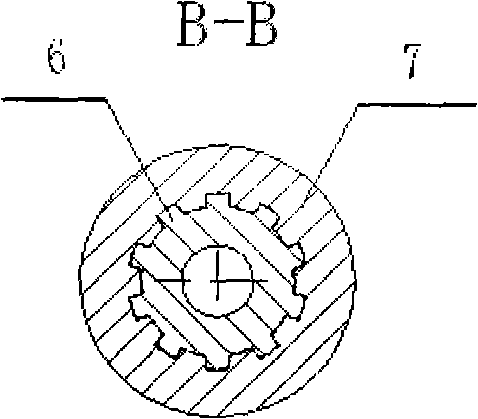

[0013] Below in conjunction with accompanying drawing, the present invention is further described, and it comprises upper conversion joint 1, sealing joint 2 on the spring, spring outer cylinder 3, spring 4, sealing joint 5 under the spring, central shaft 6, spline outer cylinder 7, Piston shaft 8, lock nut 9, water inlet valve 10, seal assembly 11, booster cylinder 12, booster cylinder centralizer 13, booster cylinder outer cylinder 14, water outlet valve 15, high pressure flow channel 16 and lower conversion joint 17. The upper conversion joint 1 is integrated with the spring upper plug joint 2, the central shaft 6 and the piston shaft 8. The central shaft 6 cooperates with the spline outer cylinder 7, which can be used to transmit torque and allow the central shaft 6 to move up and down. The central shaft 6. Connect the piston shaft 8 through the locking nut 9, the spring outer cylinder 3, the plugging joint 5 under the spring, the spline outer cylinder 7, the pressurized c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com