Toggle lever pressure transmission mechanism

A technology of transmission mechanism and toggle lever, applied in the directions of presses, punching machines, transmission devices, etc., can solve the problems of reducing the driving torque of the motor, occupying a high space, and short working range, achieving high repeat positioning accuracy, improving work efficiency, The effect of improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

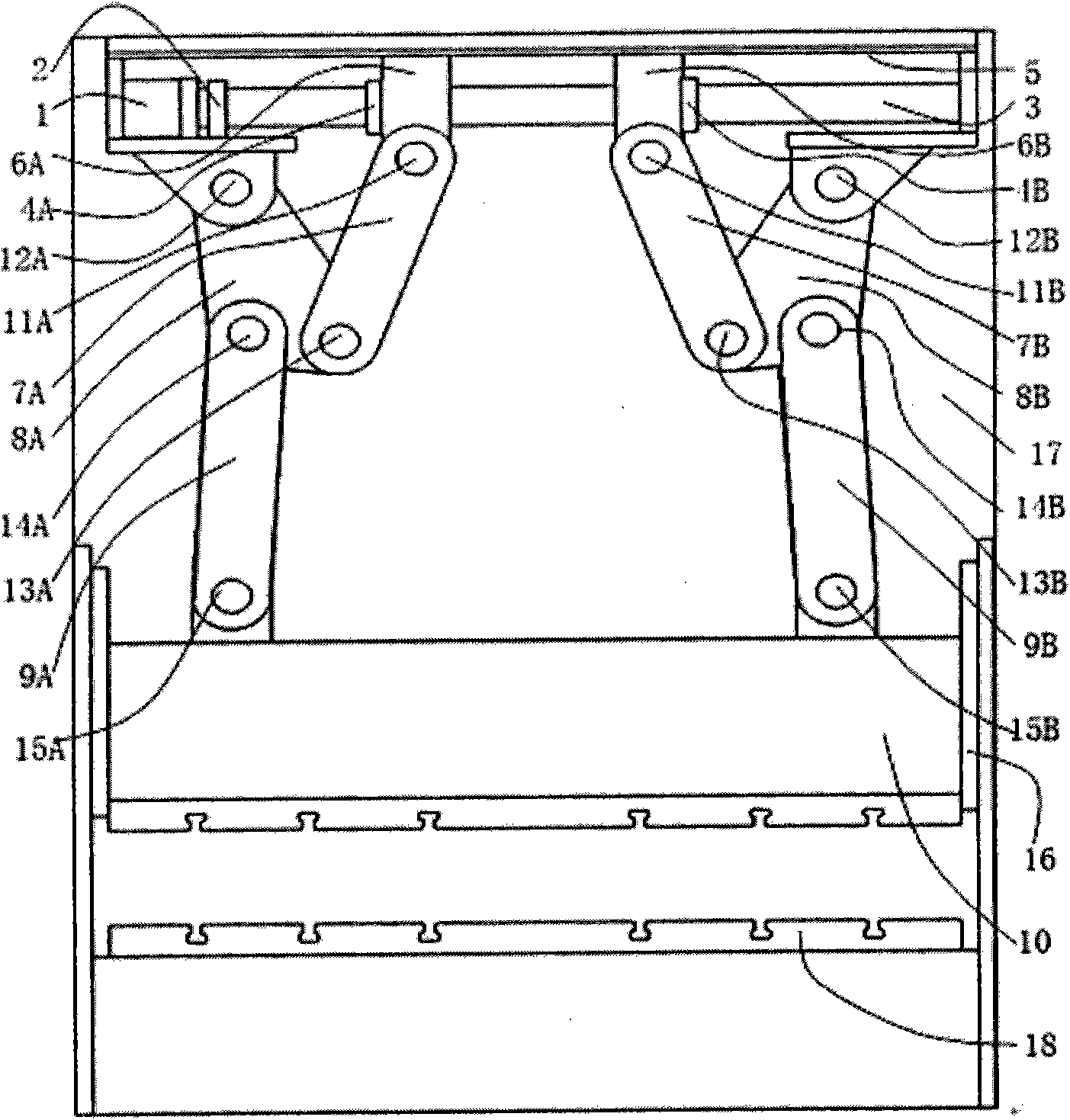

[0027] Such as figure 1 As shown, the first upper toggle plate 8A is fixed with the first upper beam hinge 12A, the first toggle hinge 14A and the first connecting hinge 13A, and the first upper toggle plate 8A is connected with the frame 17 through the first upper beam hinge 12A ; One end of the first lower toggle 9A is connected to the first upper toggle plate 8A through the first toggle hinge 14A, and the other end of the first lower toggle 9A is connected to the slider 10 through the first slider hinge 15A; the first intermediate link One end of 7A is connected to the first upper toggle plate 8A through the first connecting hinge 13A, and the other end of the first intermediate link 7A is connected to the first driving block 6A through the first driving hinge 11A.

[0028] Symmetrically, the toggle mechanism located on the right side of the vertical center line of the mechanism of the present invention is carrying out a symmetrical movement with the left side. A second up...

Embodiment 2

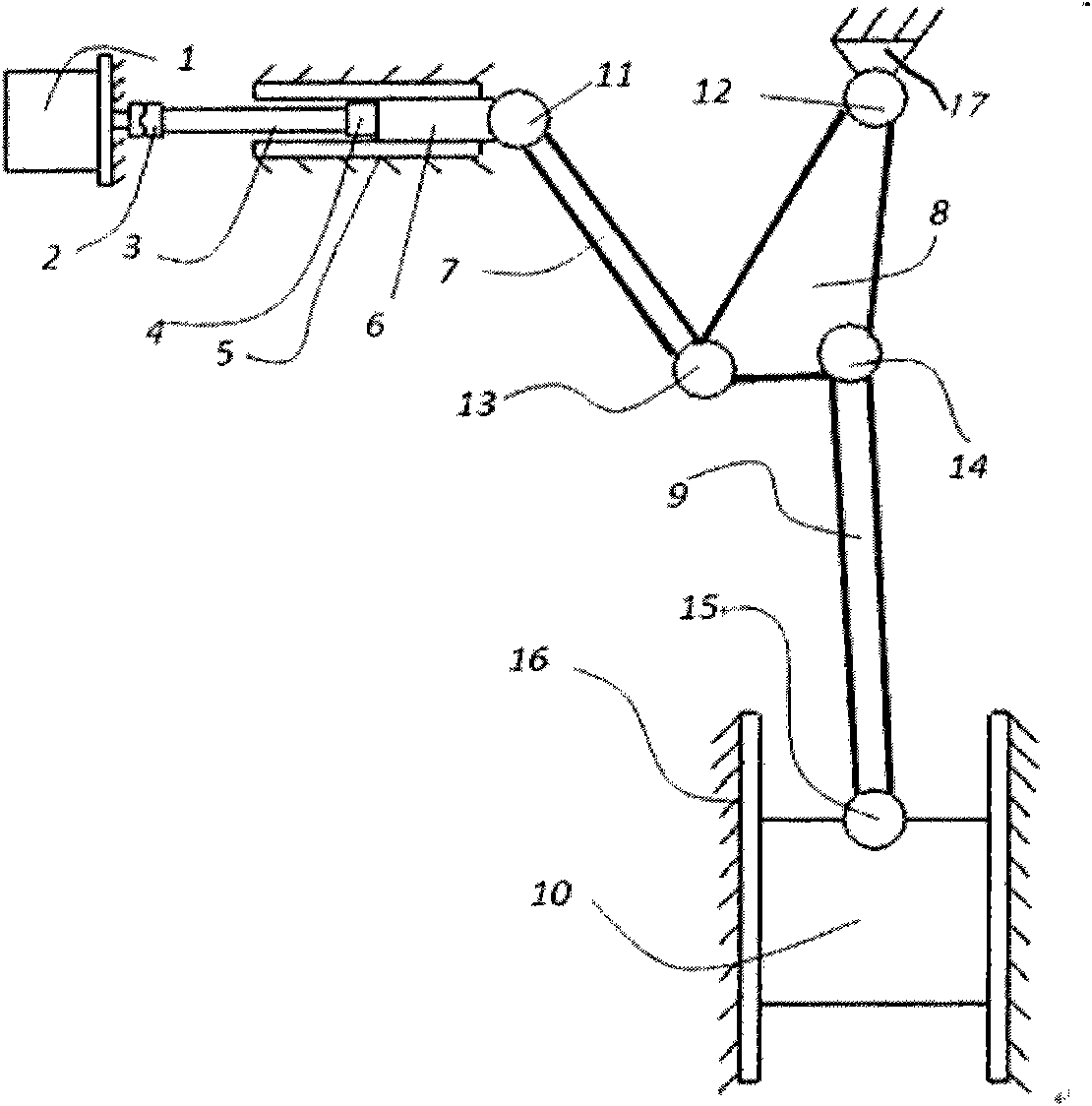

[0036] Such as figure 2 As shown, in this embodiment, the toggle pressure transmission mechanism replaces the symmetrical two toggle mechanisms in Embodiment 1 with a single toggle mechanism. The specific arrangement is as follows: the upper toggle plate 8 is fixed with an upper beam hinge 12, a toggle hinge 14 and a connecting hinge 13, and the upper toggle plate 8 is connected with the frame 17 through the upper beam hinge 12; one end of the lower toggle 9 is connected with the toggle hinge 14 It is connected with the upper toggle plate 8, and the other end of the lower toggle lever 9 is connected with the slider 10 through the slider hinge 15; one end of the intermediate link 7 is connected with the upper toggle plate 8 through the connecting hinge 13, and the other end of the intermediate link 7 is driven by The hinge 11 is connected with the driving block 6 .

[0037]The driving block 6 is connected with the intermediate connecting rod 7 through the driving hinge 11, an...

Embodiment 3

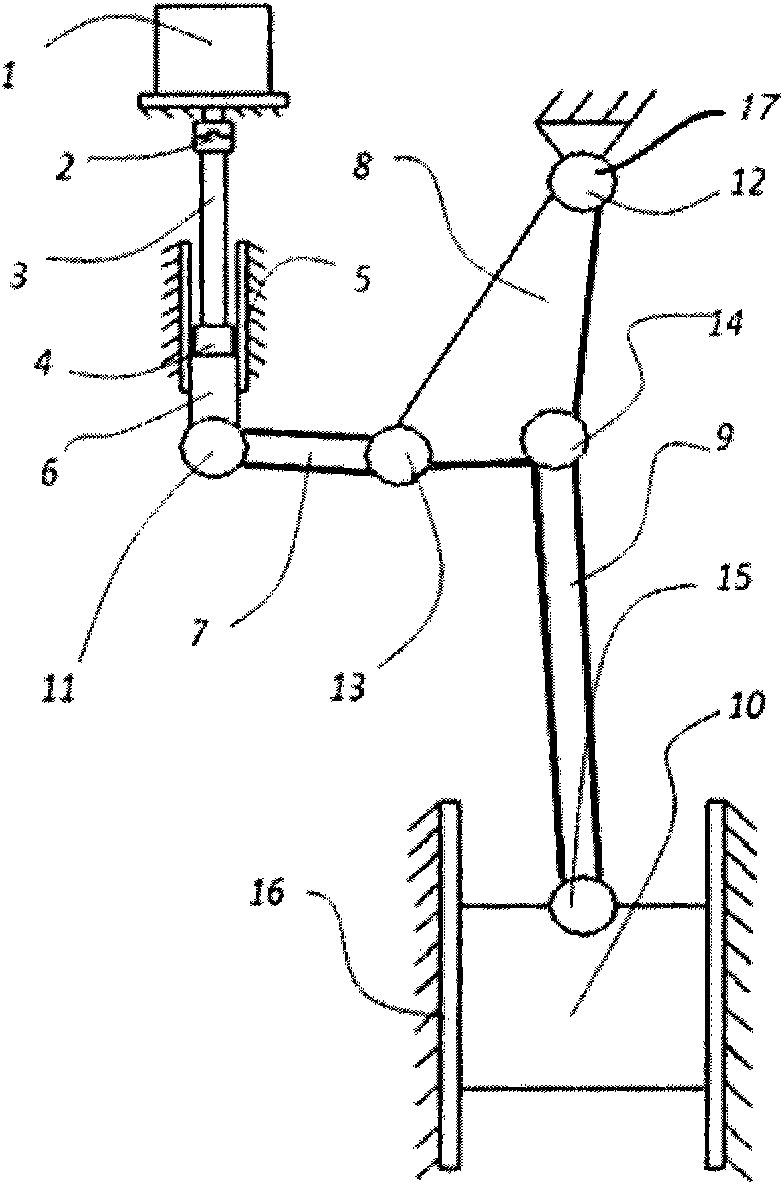

[0044] Such as image 3 As shown, in this embodiment, the motor 1, the coupling 2, the screw 3, the nut 4, the slideway 5, and the drive block 6 in the second embodiment are replaced by a vertical arrangement instead of a horizontal arrangement. The other components are the same as in the second embodiment, under the drive of the motor 1 and the screw 3, the slider can move up and down along the vertical direction.

[0045] When the connecting hinge 13 is at the farthest horizontal distance from the upper beam hinge 12, the slider 10 is at the top dead center of the stroke. When the slider 10 is at the bottom dead center of the stroke, the straight line passing through the driving hinge 11 and the connecting hinge 13 is in a horizontal state, or the straight line passing through the upper beam hinge 12 and the toggle hinge 14 is in a vertical state, or both states occur simultaneously.

[0046] The line segment connecting the axis of the hinge 12 and the axis of the drive hin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com