Deep-lying storage method of carbon dioxide

A carbon dioxide, storage method technology, applied in container filling method, gas/liquid distribution and storage, equipment loaded into pressure vessels, etc. The effect of preventing the rise of the earth's temperature and low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

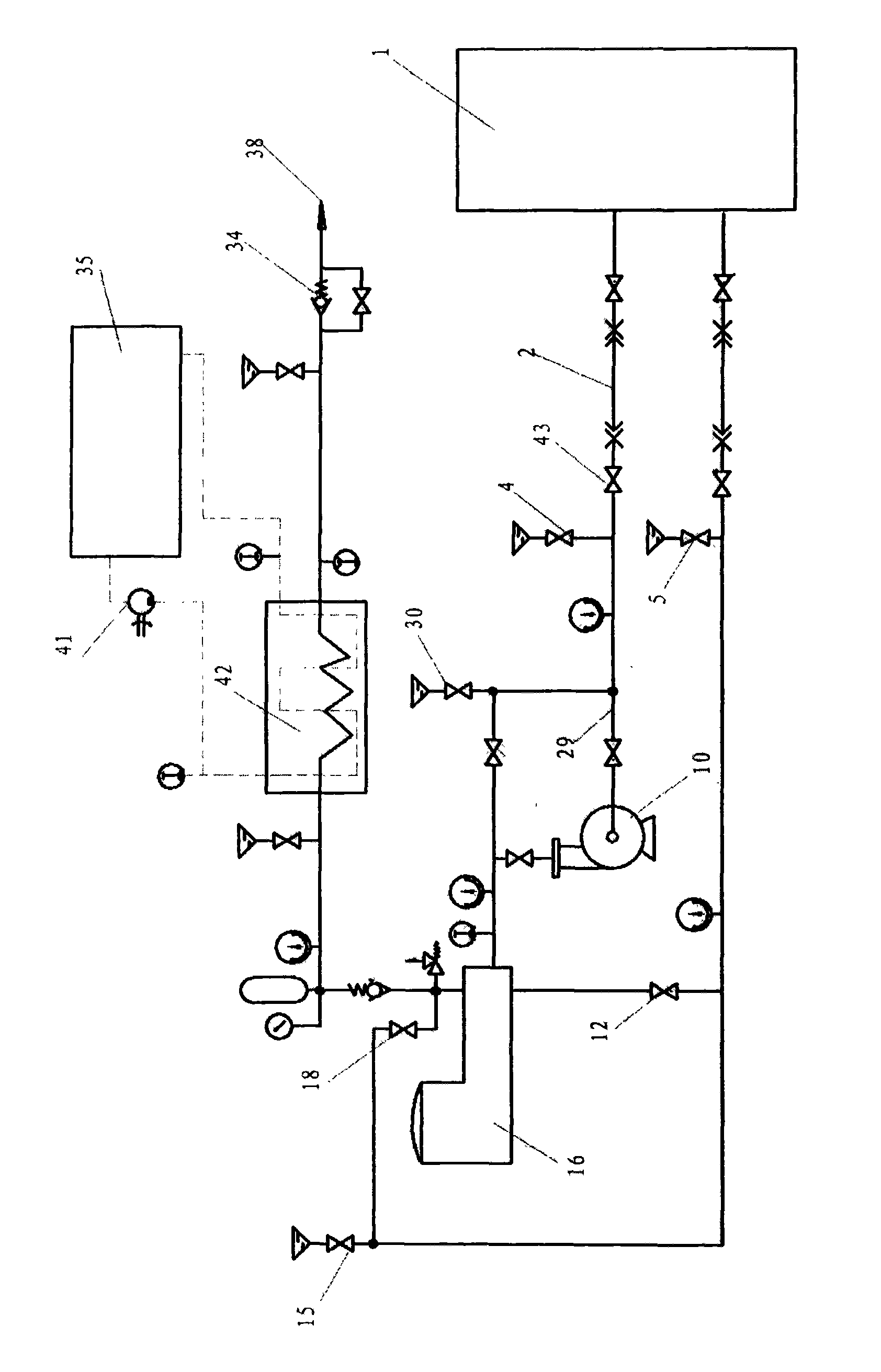

[0021] Such as figure 1 Shown, the present invention comprises the following steps:

[0022] 1) Pump the liquid-phase carbon dioxide from the tank truck or tank ship into the storage tank 1, and the output end of the carbon dioxide in the storage tank 1 is divided into gas phase and liquid phase to reach the inlet of the high-pressure pump 16, wherein the liquid phase passes through the shielded pump 10 to the inlet of the high pressure pump 16. High pressure pump 16 inlets.

[0023] 2) Liquid-phase carbon dioxide enters the high and low pressure manifolds 29 of the high pressure pump 16 and the high pressure pump 16, respectively opens the first pressure relief valve 4, the second pressure relief valve 5, and the third pressure relief valve in the high and low pressure manifolds 29 The valve 15 and the fourth pressure relief valve 30 discharge the air in the manifold 29, and the above pressure relief valve is closed for about 5-6 seconds after exhausting; The same pressure ...

Embodiment 2

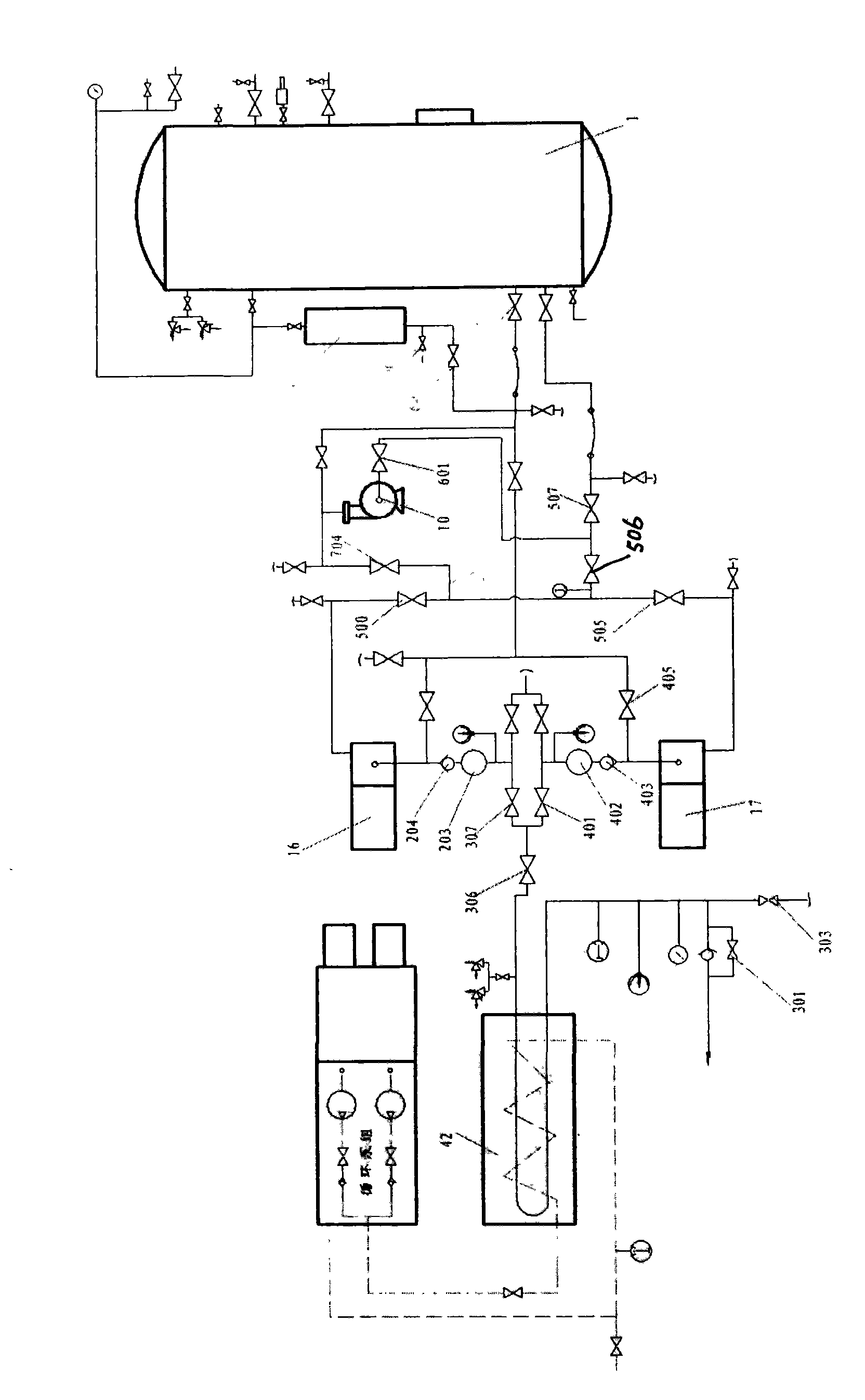

[0030] Such as figure 2 As shown, in this embodiment, two high-pressure pumps 16 and 17 are used to form a high-pressure pump group, which can accelerate the delivery speed of liquid-phase carbon dioxide. The steps of this embodiment are as follows:

[0031] 1) The output end of carbon dioxide in the storage tank 1 is divided into gas phase and liquid phase. One of the liquid phases passes through the switching valve 507 and can choose one of the two processes to run. One path enters the canned pump 10 from the inlet valve 601. No. 1 high-pressure pump 16 and No. 2 high-pressure pump 17 are supplied by delivery valve 704, No. 1 pump inlet valve 500 and No. 2 pump inlet valve 505; the other is supplied to No. 1 pump inlet valve 500 and No. No. pump inlet valve 505 inlet.

[0032] 2) The No. 1 high-pressure pump 16 and the No. 2 high-pressure pump 17 continue to raise the liquid-phase carbon dioxide to the required working pressure respectively. The No. 1 high-pressure pump 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com