Mixed small-channel cooler

A thin channel and cooler technology, which is applied in cooling/ventilation/heating transformation, instruments, semiconductor devices, etc., can solve the problems of not conforming to electronic products, large heat dissipation devices, etc., and achieve compact structure, good heat dissipation effect, and enhanced heat dissipation effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

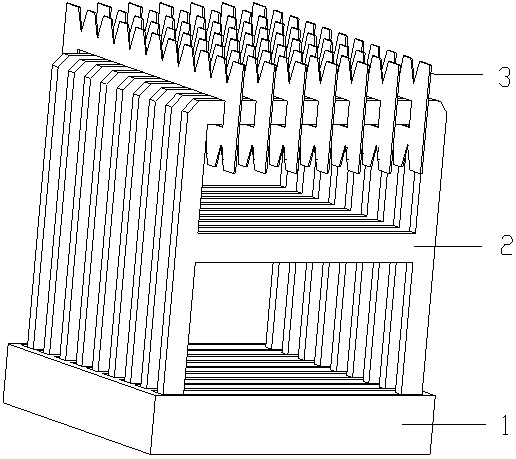

[0037] Such as figure 1 As shown, the hybrid thin-channel cooler is composed of a base 1 and a channel 2, and a set of check valves are arranged inside the channel 2, and cooling fins 3 are evenly arranged outside the channel 2. The fluid flow direction between the heat sink 3 and the contact position is greater than 0 degrees and less than or equal to 90 degrees.

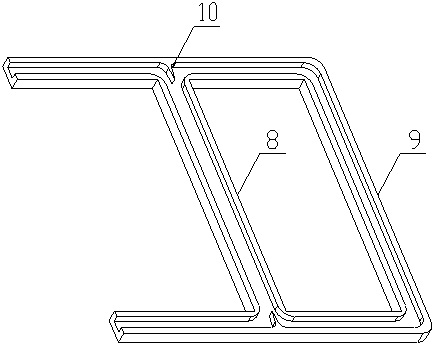

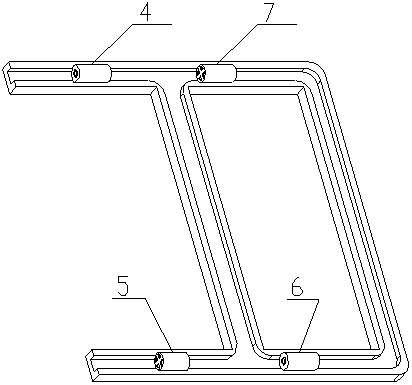

[0038] Such as figure 2 Shown, passage 2 comprises two vertical passages and cross passage A8, cross passage B9, and cross passage B9 is at the top of two vertical passages, and cross passage A8 is in the middle of two vertical passages, and between cross passage A8 and two vertical passages The upper and lower sides of the channel connection are respectively provided with one-way valve I4, one-way valve II5, one-way valve III6 and one-way valve IV7, wherein one-way valve I4, one-way valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com