Multi-row joist type large-bushing baseplate molding method and mould

A technology for forming molds and bottom molds, which is applied in the direction of manufacturing tools and glass manufacturing equipment, and can solve the problems that the shape and position accuracy of convex grooves cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

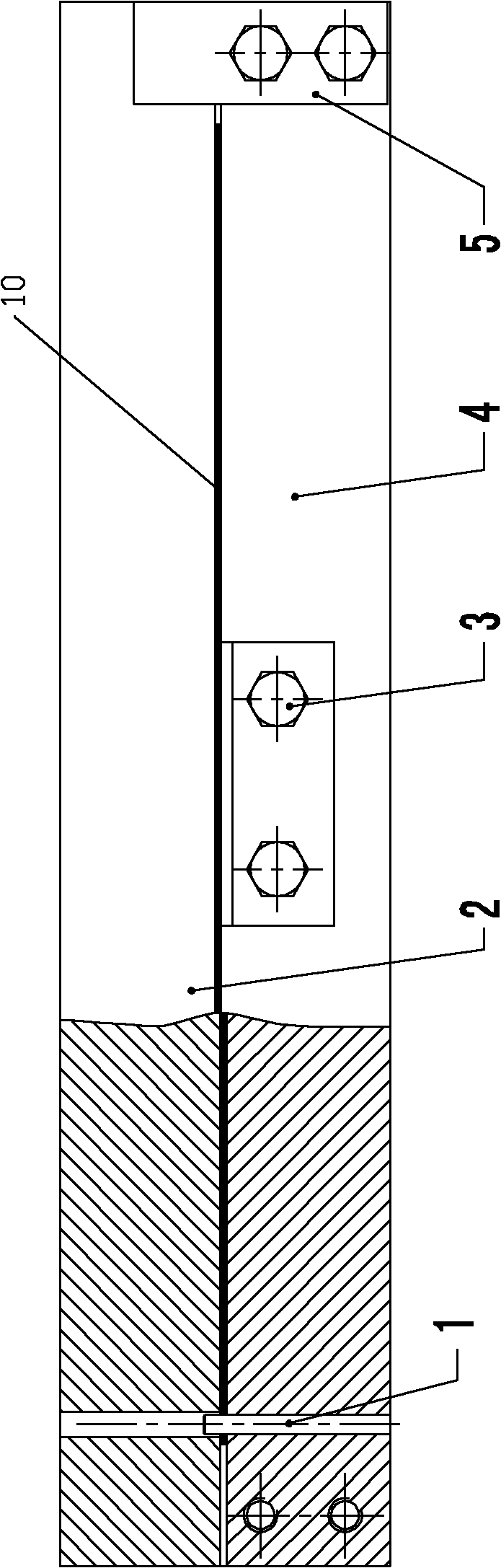

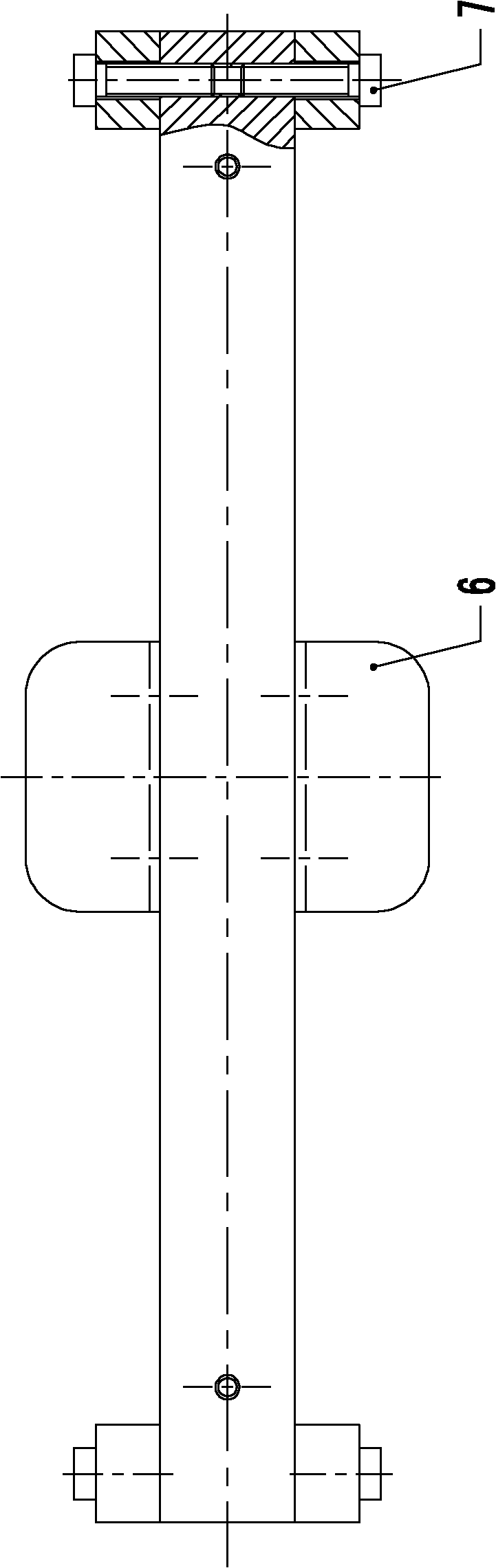

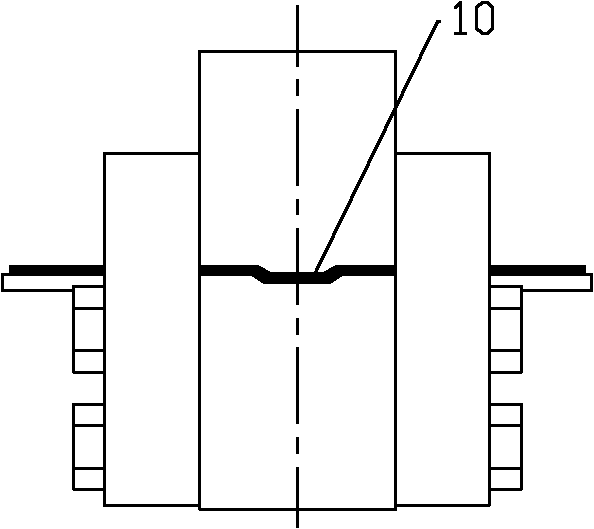

[0018] see Figure 1-3 The shown multi-row joist type large leakboard bottom plate molding die includes a corresponding upper mold (punch mold) 2 and a bottom mold (concave mold) 4 for pressing and forming a large leakboard bottom plate, and the two ends of the bottom mold are tightly Equipped with two positioning pins 1, holes corresponding to the positioning pins are provided at both ends of the upper mold. Two pairs of side stoppers 5 are respectively at the two ends near the bottom mold. Every pair of side stoppers is connected on the bottom mold by bolt 7. The inner surfaces of each pair of side stops are respectively in contact with the two side surfaces of the upper mold and the bottom mold. Two supporting plates 6 are fastened in the middle of both sides of the bottom mold by screws 3, and the upper surface of the supporting plate is flush with the upper surface of the bottom mold.

[0019] The forming method of multi-row joist type large drainboard bottom plate is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com