Exhaust hood for biomass energy converter

A technology of biomass energy and reformer, which is applied in the petroleum industry and the manufacture of combustible gas, etc. It can solve the problems of only vertical flow, easy blockage of carbon ash, and low efficiency of biomass energy reformer, so as to improve the gas production performance , to avoid the effect of dust clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

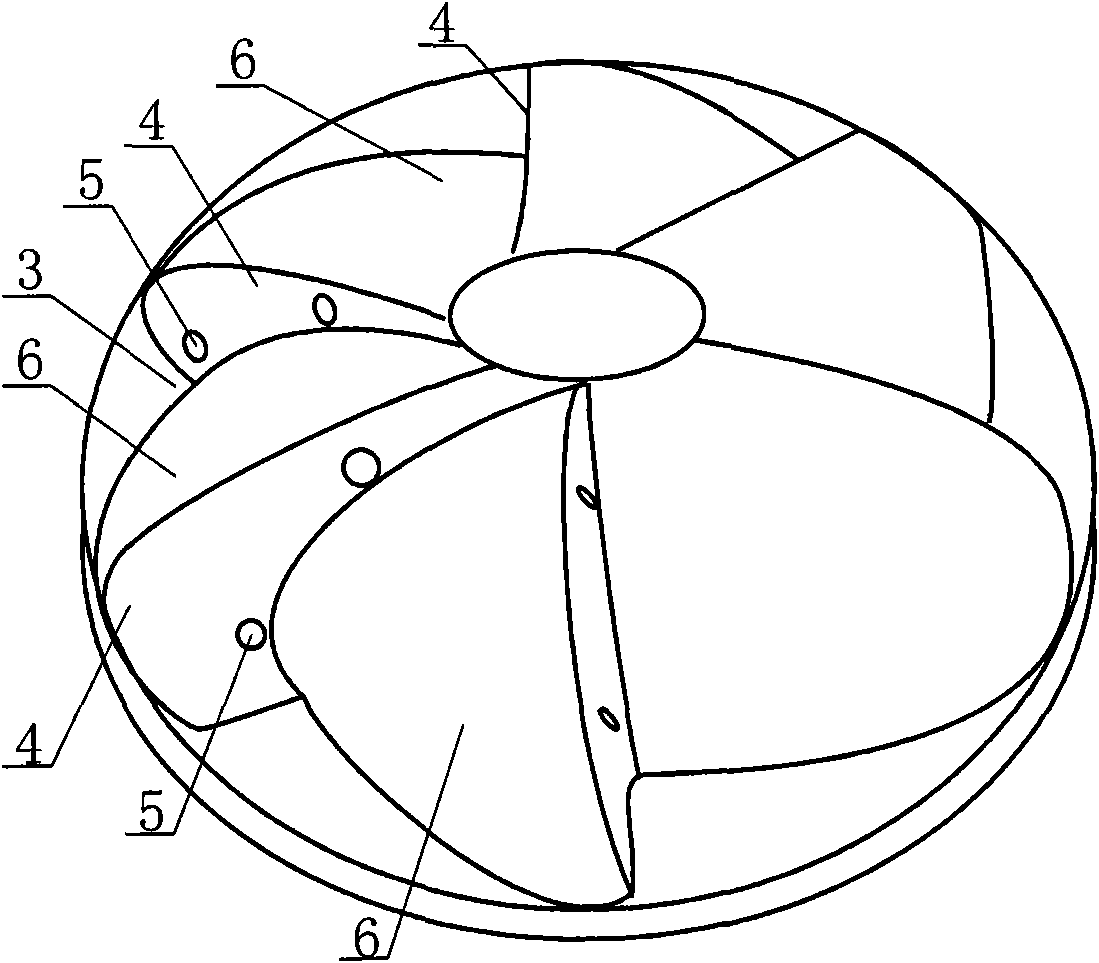

[0016] Embodiment 1: as figure 1 , figure 2 As shown, the fan hood for the biomass conversion furnace includes a cover body 1, and the inside of the cover body is a cavity 2, and a plurality of grooves 3 are distributed along the circumference on the outer surface of the cover body 1, forming a The impeller-shaped structure; the side wall 4 of the groove 3 is provided with a diffuser hole 5 , and the diffuser hole 5 communicates with the cavity 2 in the cover body 1 . One side wall 4 of the groove is perpendicular to the bottom surface, and the corresponding side wall 6 on the other side is an arc surface. The cover body is prefabricated from concrete.

Embodiment 2

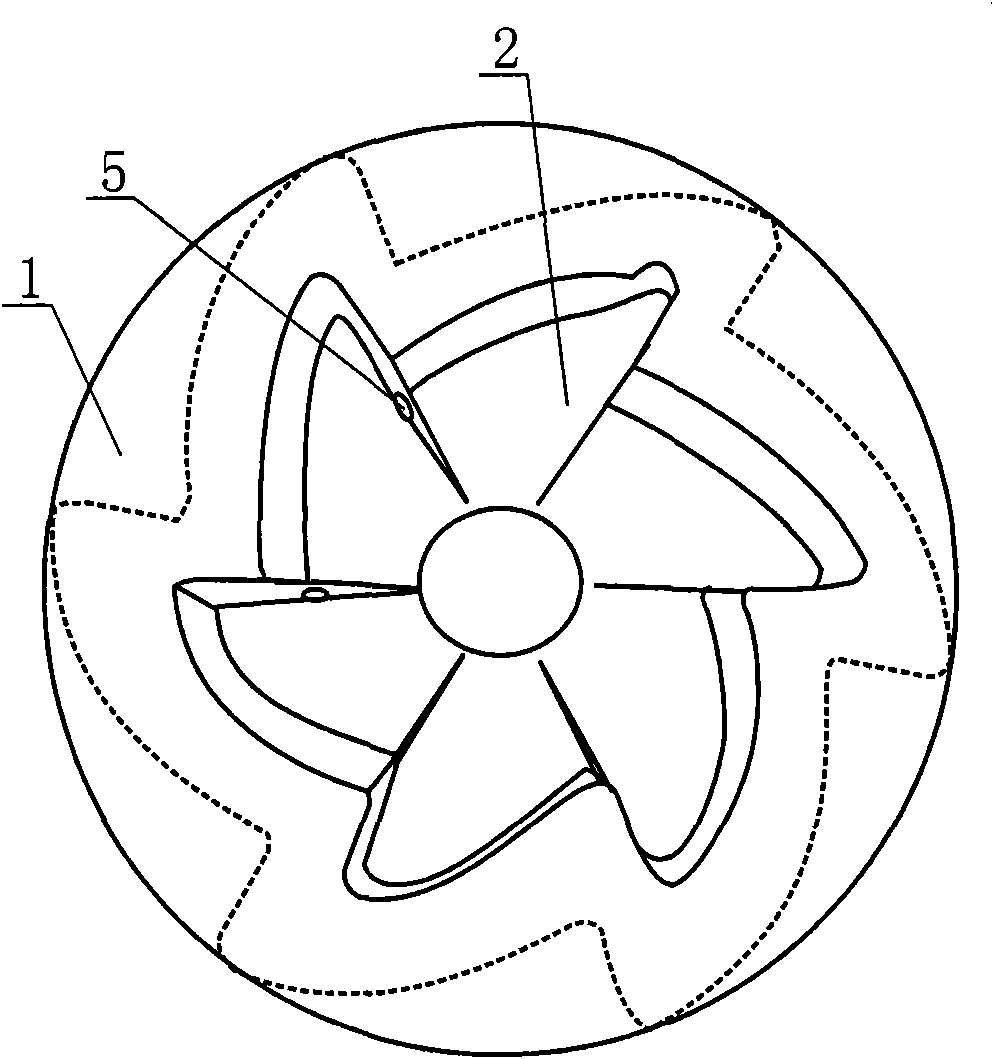

[0017] Embodiment 2: as image 3 As shown, the fan hood for the biomass conversion furnace includes a cover body 1, and the inside of the cover body is a cavity, and a plurality of grooves 3 are distributed along the circumference on the outer surface of the cover body 1; The side wall 4 of the groove 3 is provided with a diffuser hole 5 , and the diffuser hole 5 communicates with the cavity in the cover body 1 . The cover body is made of metal plate.

Embodiment 3

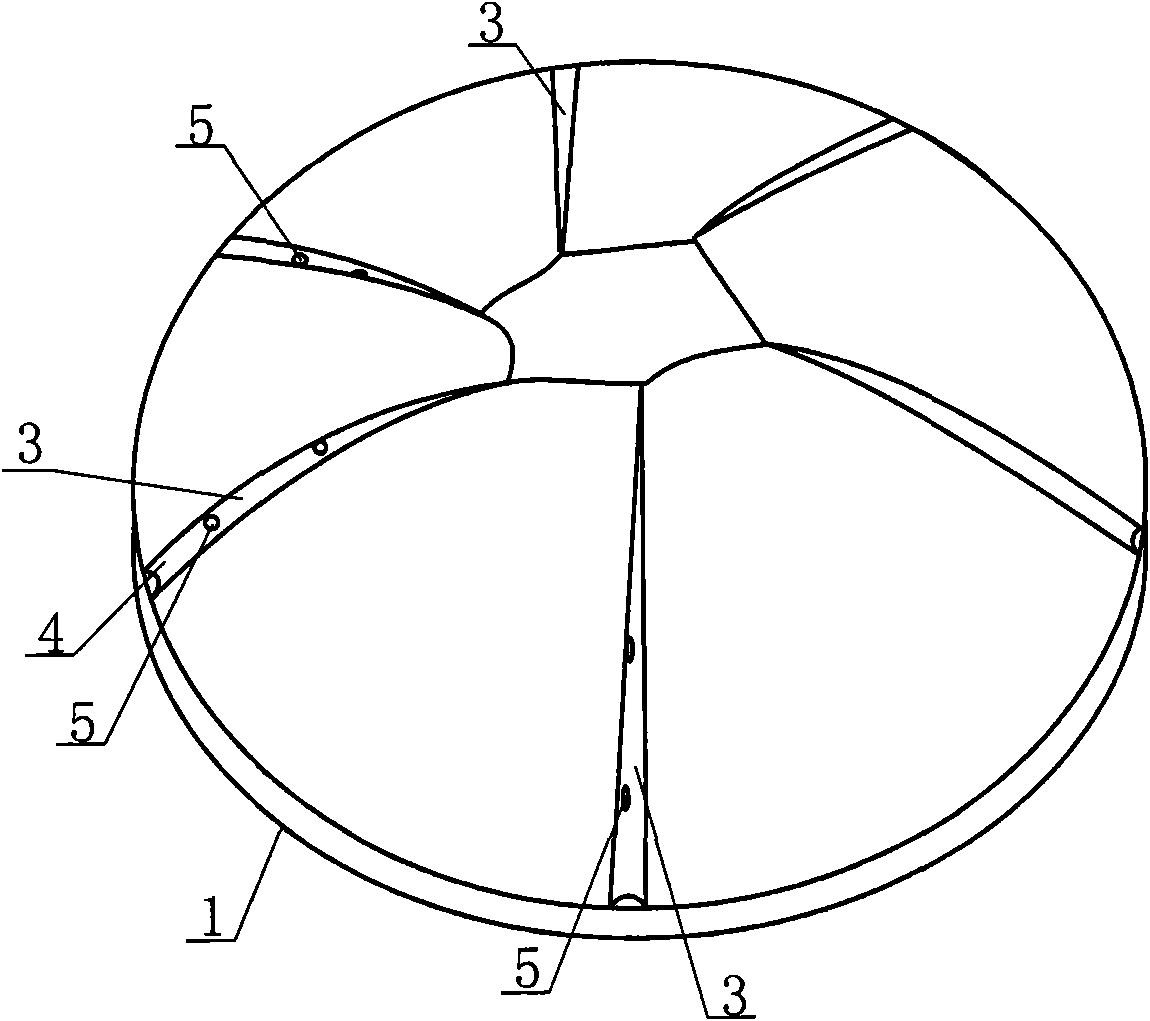

[0018] Embodiment 3: as Figure 4 As shown, the fan hood for the biomass conversion furnace includes a cover body 1, and the inside of the cover body is a cavity, and a plurality of grooves 3 are distributed along the circumference on the outer surface of the cover body 1; The side wall 4 of the groove 3 is provided with a diffuser hole 5 , and the diffuser hole 5 communicates with the cavity in the cover body 1 . The cover body is prefabricated from concrete. The outer surface of the cover body 1 is provided with two concentric air guiding inner rings 7 and air guiding outer rings 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com