Concrete gravity pillar type retaining wall

A technology for concrete piers and concrete, applied in the field of construction, can solve the problems of large impact on the surrounding environment, large working surface, vibration, high noise, etc., and achieve the effect of reducing the amount of engineering, balancing the stress of the base, and increasing the resistance moment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

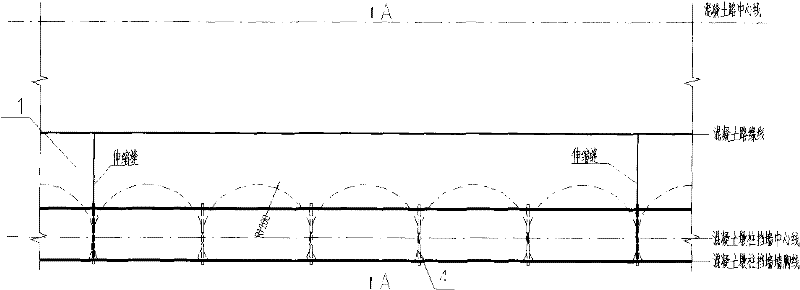

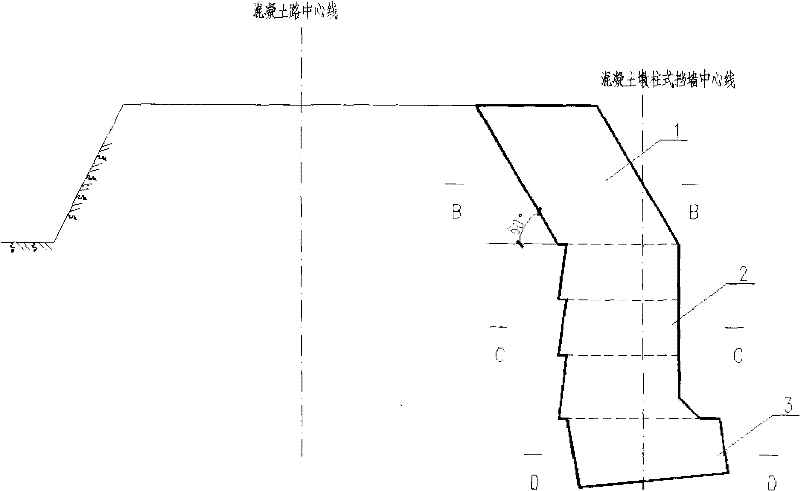

[0025] The concrete gravity pier type retaining wall of the present invention uses its own gravity to maintain the stability of the retaining wall under the action of water, earth pressure and vehicle load. The diameter of a single concrete pier is determined according to the bearing capacity of the foundation, the height of the retaining soil, the condition of the piled soil and the load of the vehicle. Generally, it is 1.6m-3.6m. The cross-section of the entire wall body is divided into three parts: the upper inclined parallelogram 1 (referred to as head-up), the middle chord-cut circle 2 (referred to as slimming), and the bottom gradual chord-cut circle 3 (referred to as heel cut). The upper elevation angle ranges from 80° to 45°, and the height accounts for about 1 / 3 of the total height of the entire wall. The different inclination angles of the inclined part determine the backward movement of the center of gravity of the entire wall, and the difference in height determines...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com