Vacuum insulating board with built-in absorber

A technology of vacuum insulation panels and absorbers, applied in heat exchange equipment, protecting pipelines through heat insulation, heat preservation, etc., can solve problems such as drying that are not mentioned, and achieve the goal of reducing thermal conductivity, improving heat insulation effect, and increasing vacuum degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

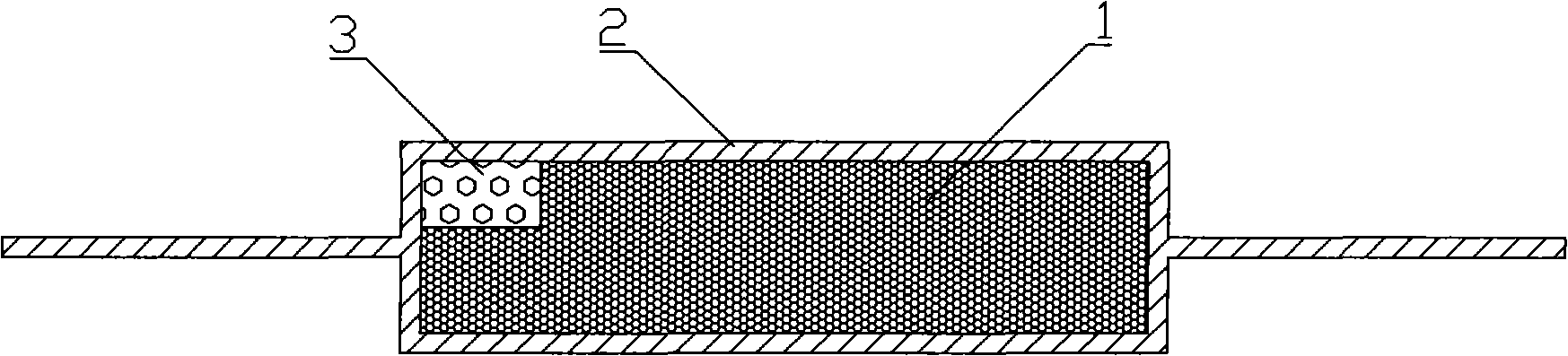

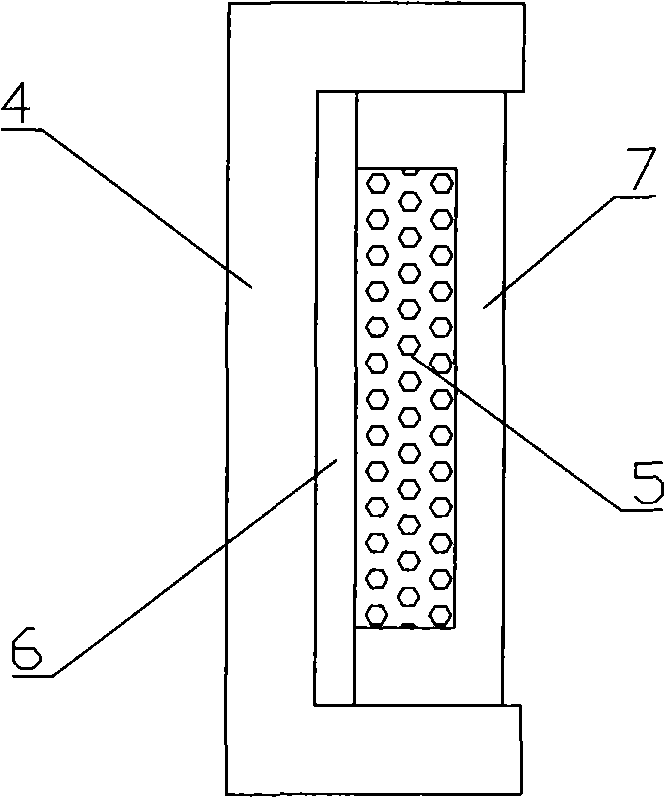

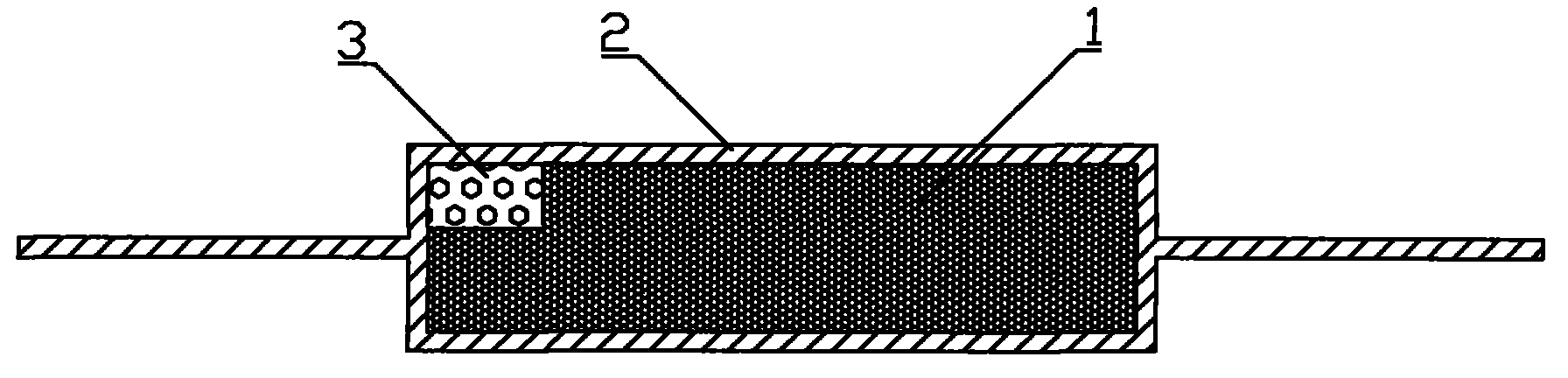

[0016] figure 1 It is a structural schematic diagram of the present invention; figure 2 It is a schematic diagram of the structure of the absorber, as shown in the figure: the vacuum insulation panel with built-in absorber in this embodiment includes a glass fiber core material 1, an aluminum foil 2 sealed and wrapped outside the glass fiber core material 1, and an aluminum foil 2 arranged inside Absorber 3 for absorbing water, the inside of aluminum foil 2 is evacuated, said absorber 3 includes absorbent container 4 and absorbent 5 arranged in absorbent container 4, said absorbent 5 includes quicklime and zeolite, made of quicklime and According to the chemical properties of zeolite, quicklime and water can produce CaO+H 2 O→Ca(OH) 2 The chemical reaction has strong water absorption. At the same time, zeolite also has strong water absorption and can be used as a desiccant. The quicklime and zeolite are both granular, and the particle size is 1-5mm. If the particle size is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com