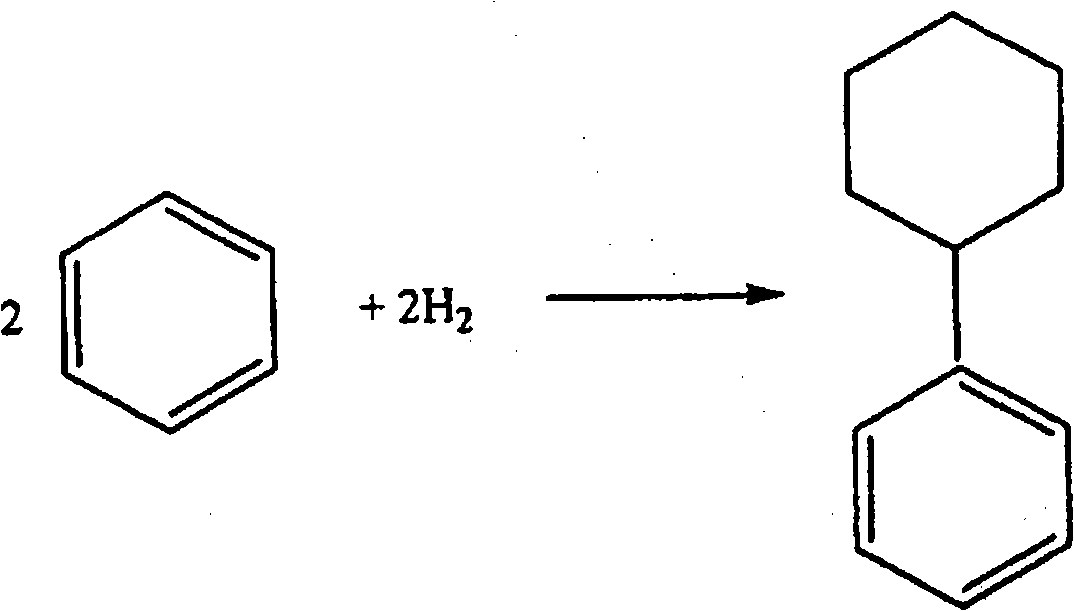

Process for producing cyclohexylbenzene

A technology of cyclohexylbenzene and cyclohexanone, applied in the field of preparing cyclohexylbenzene, can solve problems such as the increase of the cost of propylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0059]To illustrate the importance of the location of the hydrogenation metal in hydroalkylation, Table 1 below compares the presence of the same amount of palladium, but with palladium on a molecular sieve (catalyst A) or on an inorganic oxide support (catalyst B). Performance of two catalysts A and B. Both catalysts contained 0.006 g of Pd and 1.6 g of MCM-49, with Catalyst A containing 0.4 g gamma alumina support and Catalyst B containing 2.0 g gamma alumina support.

[0060] Catalyst A was prepared by depositing palladium onto MCM-49 zeolite by incipient wetness technique. The gamma alumina was then added to the Pd-impregnated MCM-49 to form a mixture. The mixture was then pelletized using a hand press at 136,000 kPaa for 60 seconds to form pellets. The pellets were then sized to pass through 0.841 mm openings but not 0.250 mm openings (20 / 60 mesh pellets) and tested for benzene hydroalkylation performance. With Catalyst A, all palladium was on molecular sieves.

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com