Lower opening type coke discharging ducting device

A conduction device and bottom-opening technology, which is applied in the field of bottom-opening coke discharge smoke and dust conduction device, can solve the problem of large air leakage rate between the control rod and the valve body, increased equipment capacity of the ground dust removal station, increased initial investment and operating costs and other problems, to achieve the effect of saving initial investment and operating costs, saving investment and saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

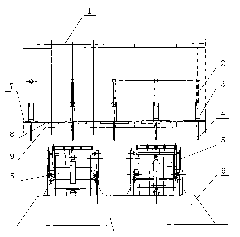

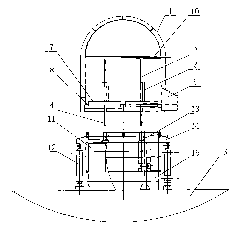

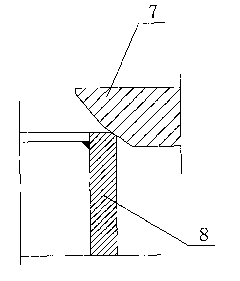

[0026] A downward-opening type coke smoke and dust conduction device, such as figure 1 and figure 2 As shown, the device is arranged above the suction hood 6 of the coke guide car, and can be fixed by a bracket on the coke oven column. The device structure includes a gas collection pipe 1, a valve group and a docking device 5. A chassis bracket 9 is provided, the valve group is fixedly installed on the chassis bracket 9, and the docking device 5 is installed on the top of the suction hood 6 of the coke guide car and corresponds to the position of the valve group. The valve group is composed of several smoke outlet valves. Each smoke outlet valve includes a valve plate 7, a valve seat 8, a push rod 4 and a guide seat 3. The push rod 4 and the guide seat 3 are respectively vertically fixed on the two side plates of the valve plate 7. surface, such as image 3 As shown, the valve plate 7 and the valve seat 8 are fitted together with each other, and the valve seat 8 and the cha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap