Corestone manufacture method

A production method and core technology, applied in earthwork drilling, wellbore/well components, etc., can solve the problems of not being able to observe the distribution of oil and water in the core, inconvenient test and analysis work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with embodiment:

[0042] The manufacturing method of 60×60×10cm multi-electrode epoxy resin cemented artificial rock core comprises the following steps:

[0043] (1) Mold making:

[0044] The mold is composed of side plates, end plates, bottom plates and pressure plates. The bottom plate and pressure plate are made of hard miscellaneous wood, and the rest are made of carbon steel. There is a set of holes on the end faces of the two side plates, and the two side plates are connected together by bolts;

[0045] (2) Ingredients:

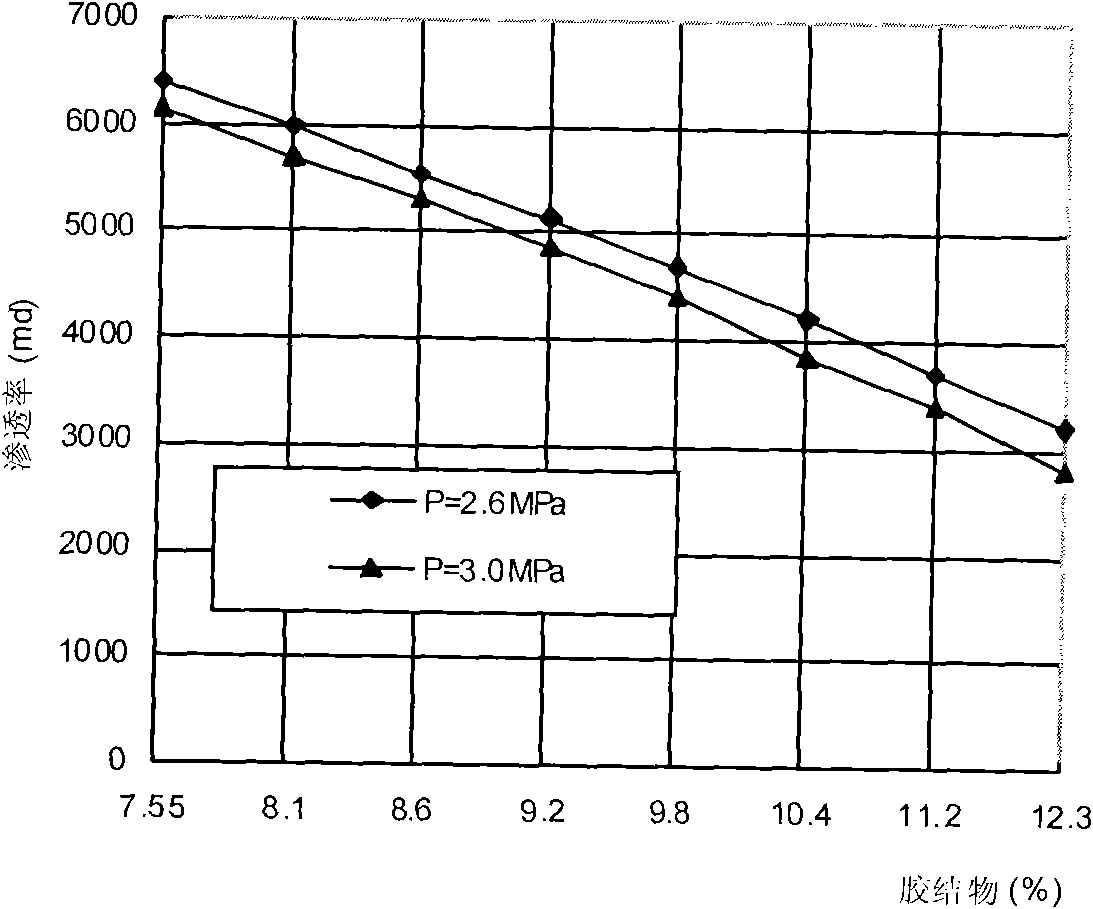

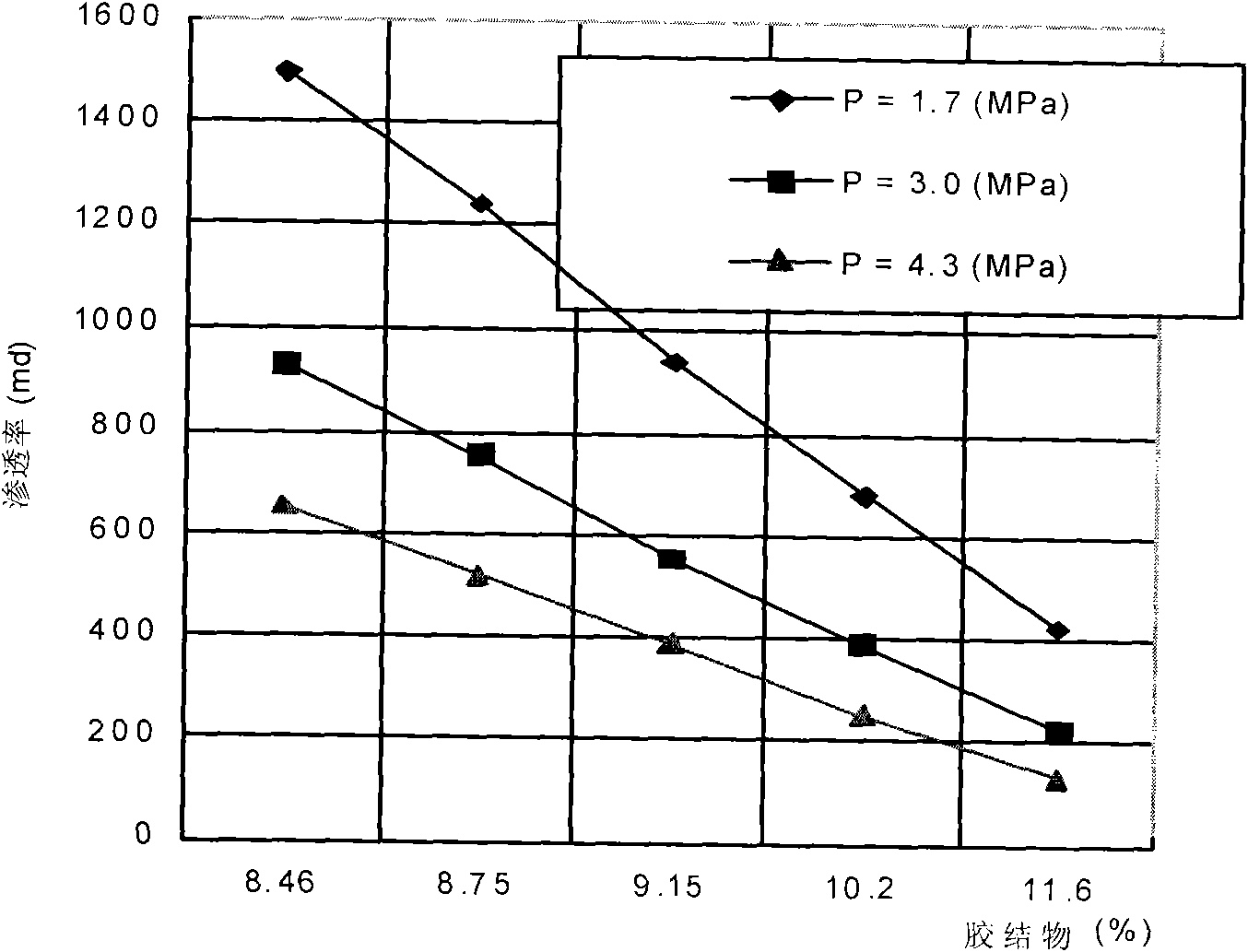

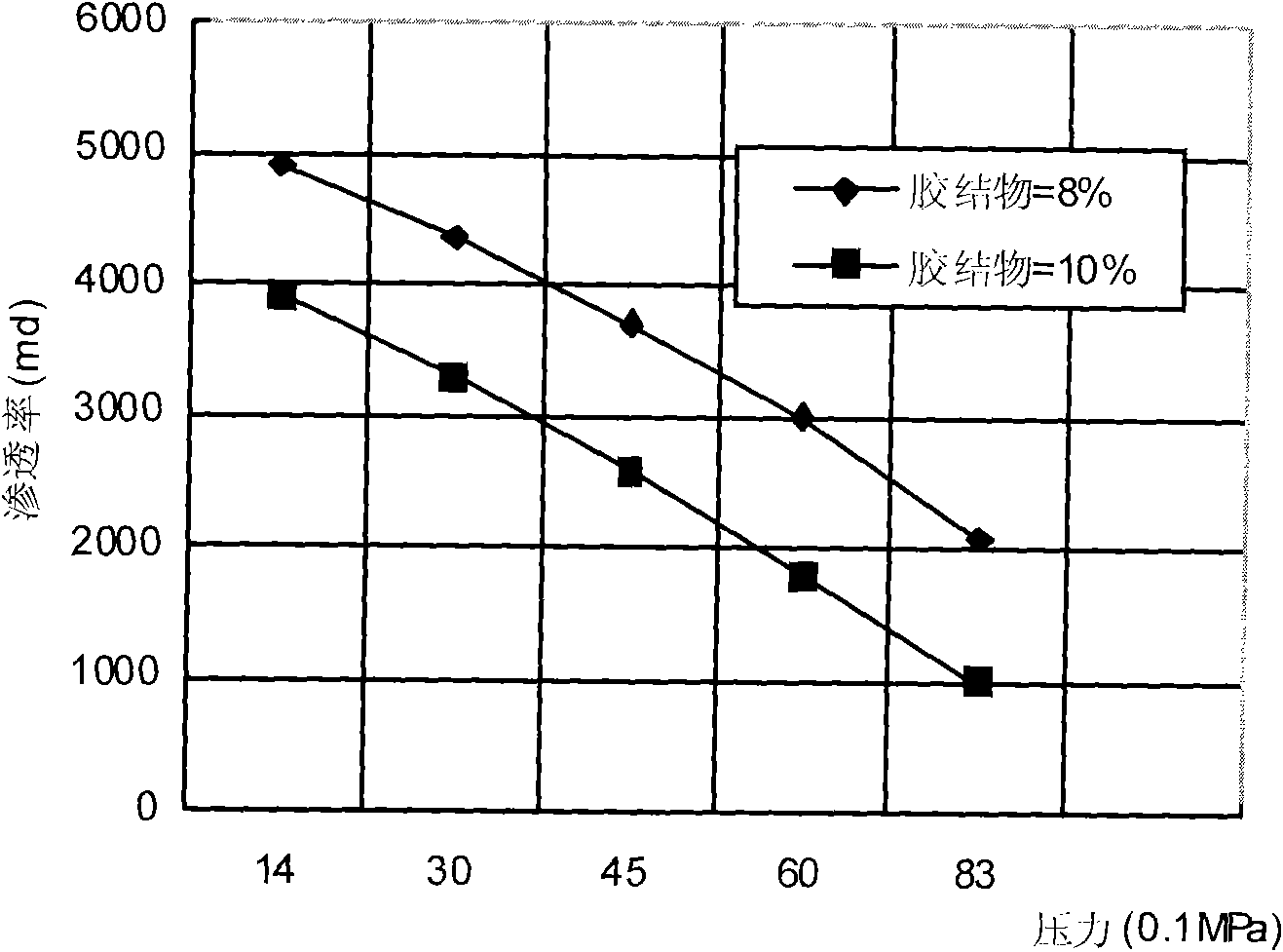

[0046] The model making material is composed of quartz sand and cement, and the proportion of quartz sand and cement is in parts by weight. 100 parts of quartz sand require 9 to 13 parts of epoxy resin cement, and the composition of epoxy resin cement is 1g of epoxy resin Add 0.2mL softener dibutyl phthalate, 0.08g curing agent ethylenediamine and 0.3mL-0.5mL diluent acetone;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com