Fault prediction method and device thereof for rotation equipment

A technology for rotating equipment and fault prediction. It is used in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc. It can solve the problems of heavy load, harsh working conditions, and narrow practical range, and achieve high judgment success rate and high judgment value. , the effect of high computing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

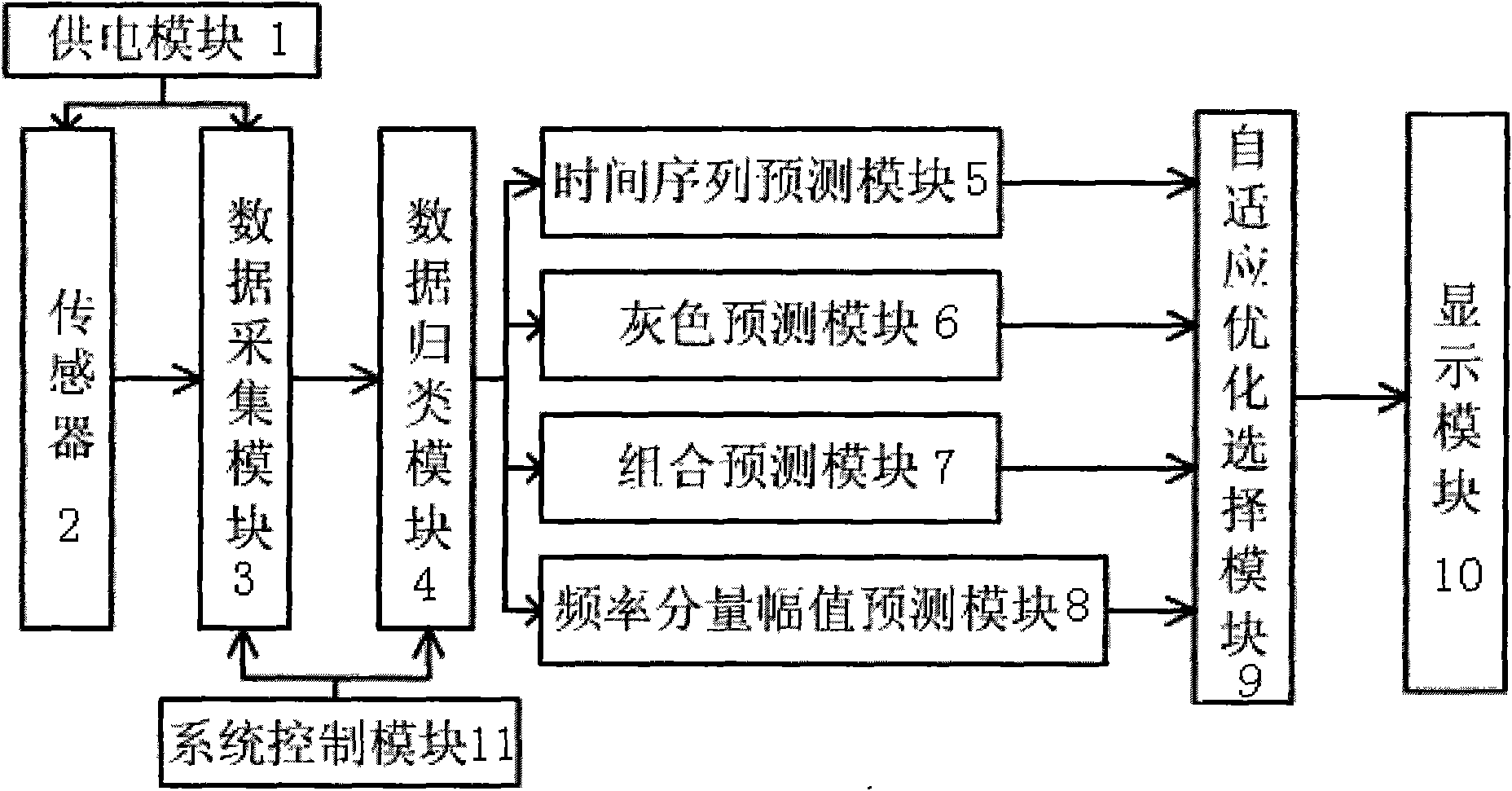

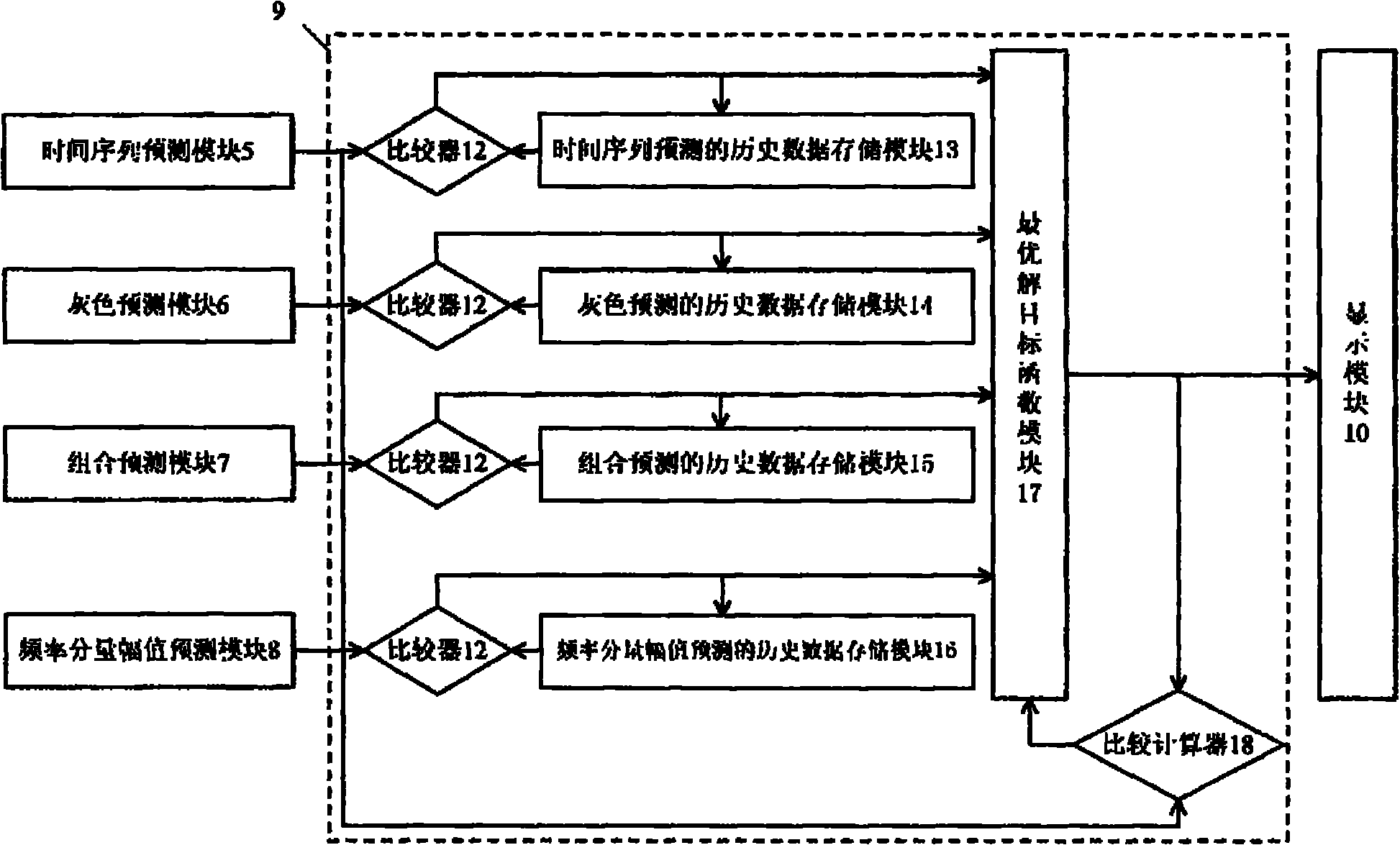

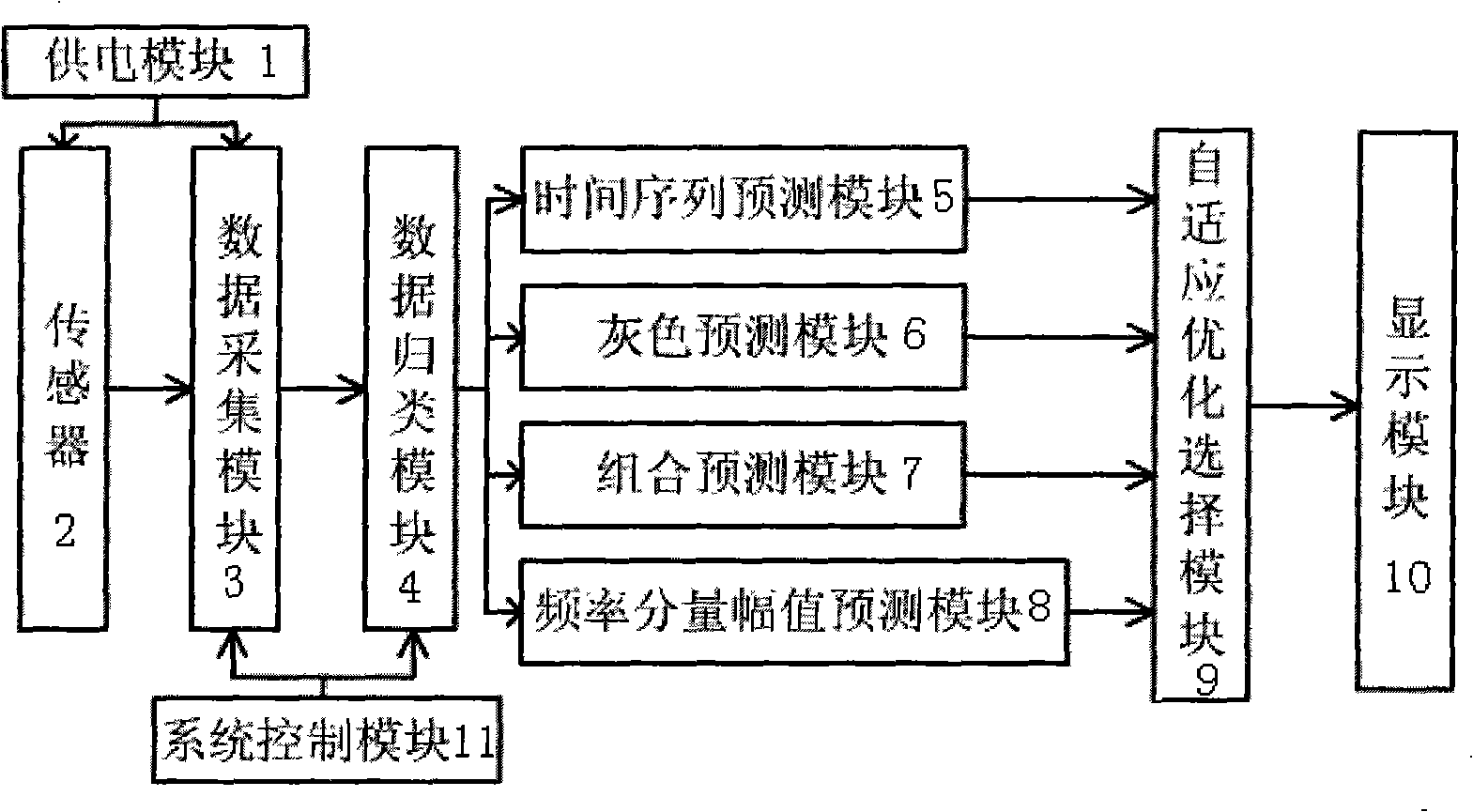

[0014] Such as figure 1 As shown, the present invention includes a power supply module 1, a sensor 2, a data acquisition module 3, a data classification module 4, a time series prediction module 5, a gray prediction module 6, a combined prediction module 7, a frequency component Amplitude prediction module 8, an adaptive optimization selection module 9, a display module 10 and a system control module 11; the output terminals of the power supply module 1 are respectively connected with the sensor 2 and the data acquisition module 3 to realize its power supply function. The sensor 2 sends the detected vibration signal into the data acquisition module 3, and then the data acquisition module 3 sends the vibration signal into the data classification module 4 for classification processing, and then sends it to the time series prediction module 5 and the gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com