High-frequency hardening monitor device

A technology of high-frequency quenching and monitoring devices, which is applied in the direction of induction heating devices, energy efficiency, process efficiency, etc., and can solve the problems of low effective power and inability to monitor the effective power, frequency, and phase difference changes of high-frequency quenching treatment. , to achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

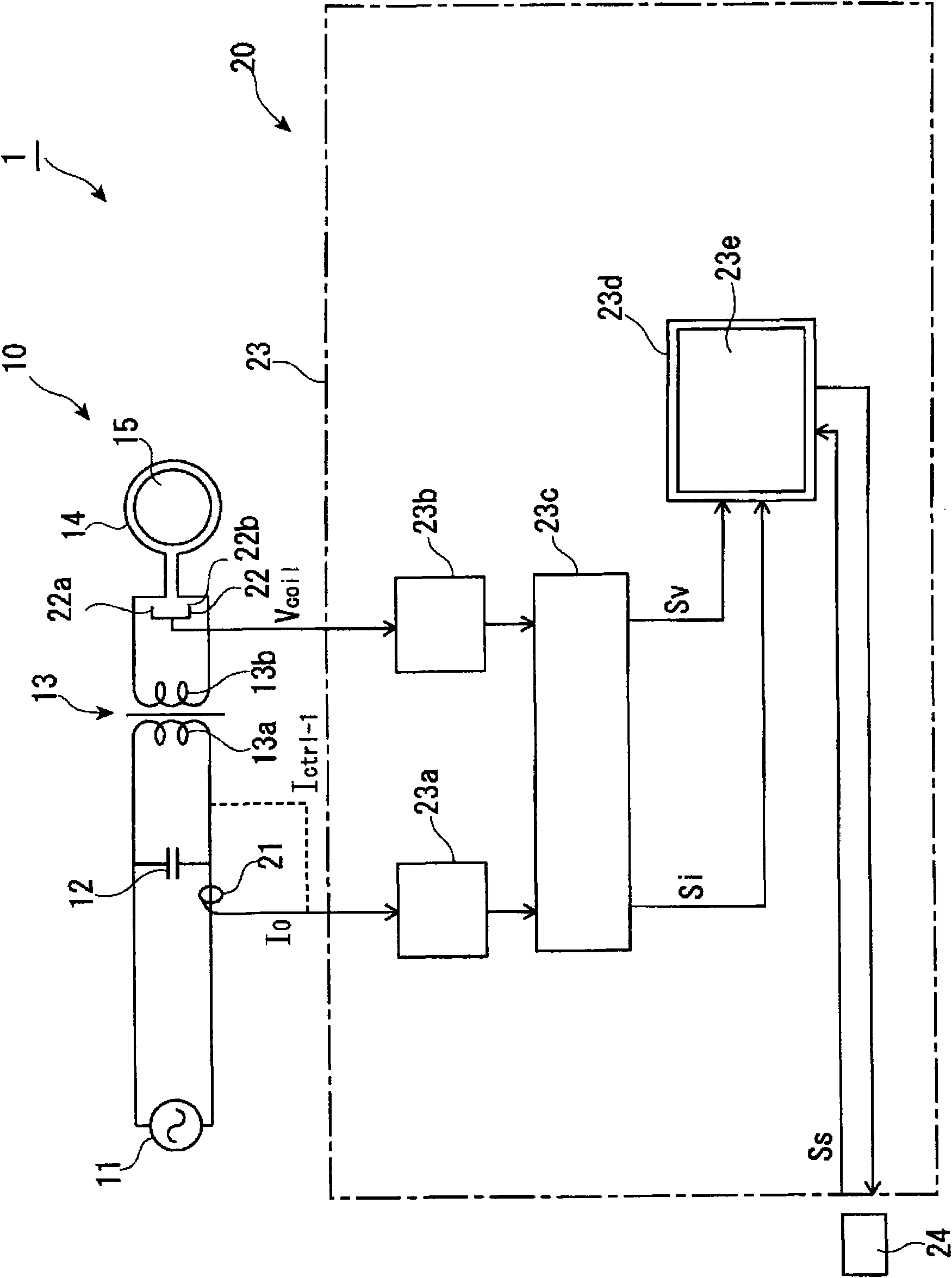

[0052] The induction hardening monitoring device according to the first embodiment ensures the quality of induction hardening by monitoring the output current from the high-frequency inverter and the voltage generated across the heating coil. figure 1 It is a figure which shows the structure of the induction hardening system equipped with the induction hardening monitoring apparatus which concerns on 1st Embodiment. The induction hardening system 1 is composed of an induction hardening device 10 and an induction hardening monitoring device 20 .

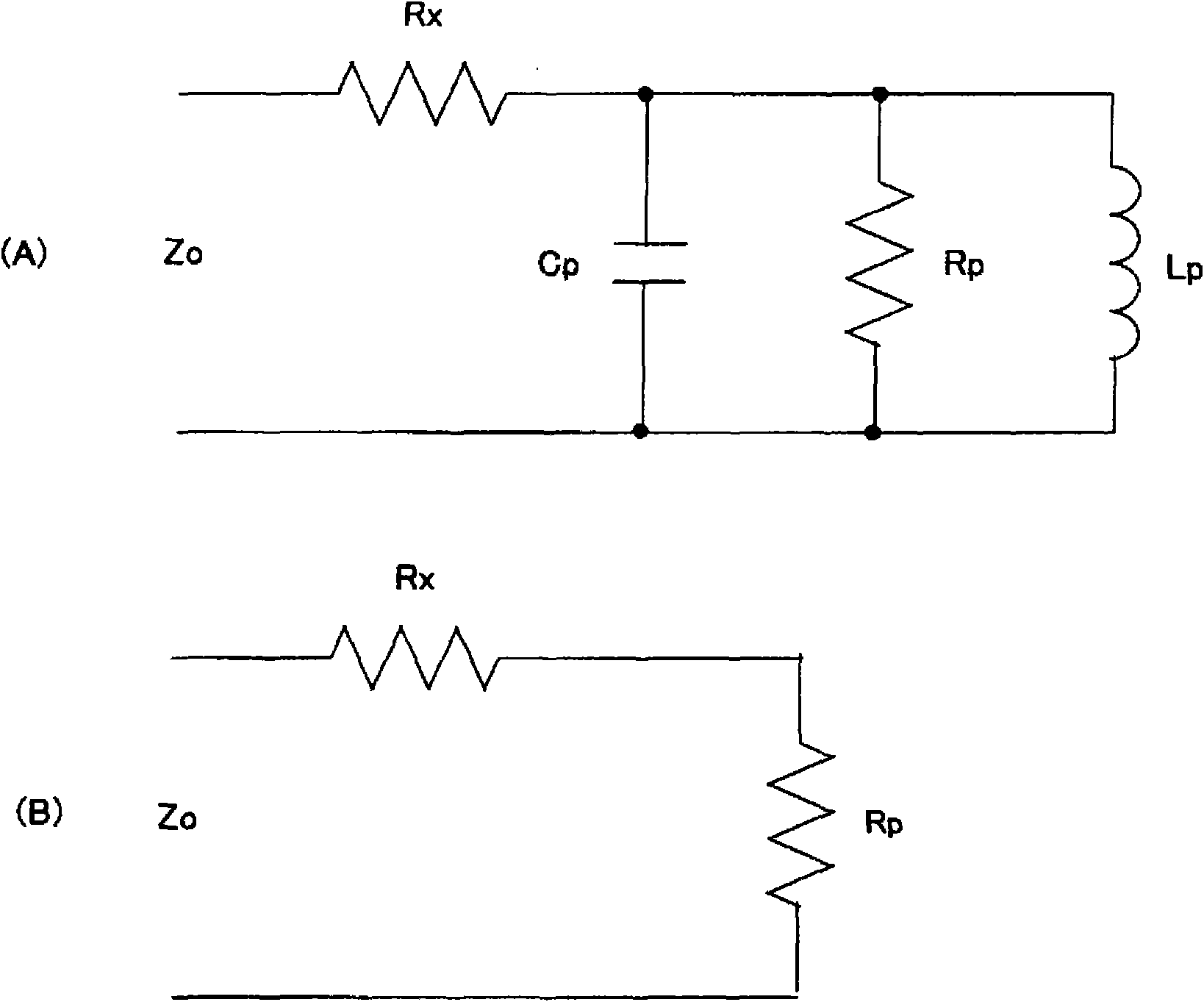

[0053] The high-frequency quenching device 10 is composed of the following parts on the circuit: a high-frequency inverter 11; a capacitor 12 for matching, which is connected between the output terminals of the high-frequency inverter 11; induction heating; and a current transformer 13 which exists between the capacitor 12 for matching and the heating coil 14 . Accordingly, the induction hardening device 10 is constituted as a reson...

no. 2 approach

[0080] In the second embodiment, during induction hardening, the normality of the induction hardening process is monitored by monitoring the value obtained by dividing the heating coil voltage by the output current output from the high-frequency inverter, that is, the load impedance. The configuration of the induction hardening system equipped with the quenching monitoring device according to the second embodiment is the same as that shown in the first embodiment. figure 1 The situation is the same. That is, the induction hardening system equipped with the induction hardening monitoring device according to the second embodiment, specifically, the impedance monitoring device is installed, such as figure 1 As shown, it consists of an induction hardening device 10 and a quenching monitoring device 20 .

[0081] Such as figure 1As shown, the induction hardening device 10 is constituted as a resonant circuit in which a capacitor 12 for matching and a heating coil 14 are connec...

Embodiment 1

[0128] use figure 1 The shown induction hardening system 1 was subjected to a load evaluation test.

[0129] As the high-frequency inverter 11 , an inverter that outputs a high frequency with a frequency of 25 kHz by performing constant control with a DC voltage is used. As a parallel resonance type load circuit, a matching capacitor 12 of 10 μF and a current transformer 13 with a turn ratio of 6:1 were used. As the saddle-shaped support part which built the heating coil 14 and supported the workpiece|work 15, the support part with an inner diameter of 40 mm and a width of 4 mm was used. A round pipe with an outer shape of 33 mm and a wall thickness of 5.5 mm was used as the workpiece 15 . In Example 1, the workpiece 15 was arranged so that the gap between the outer shape of the workpiece and the end surface of the saddle-shaped support portion was a standard value of 4 mm. The output of the high-frequency inverter 11 is set so that the output power of the high-frequency i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com