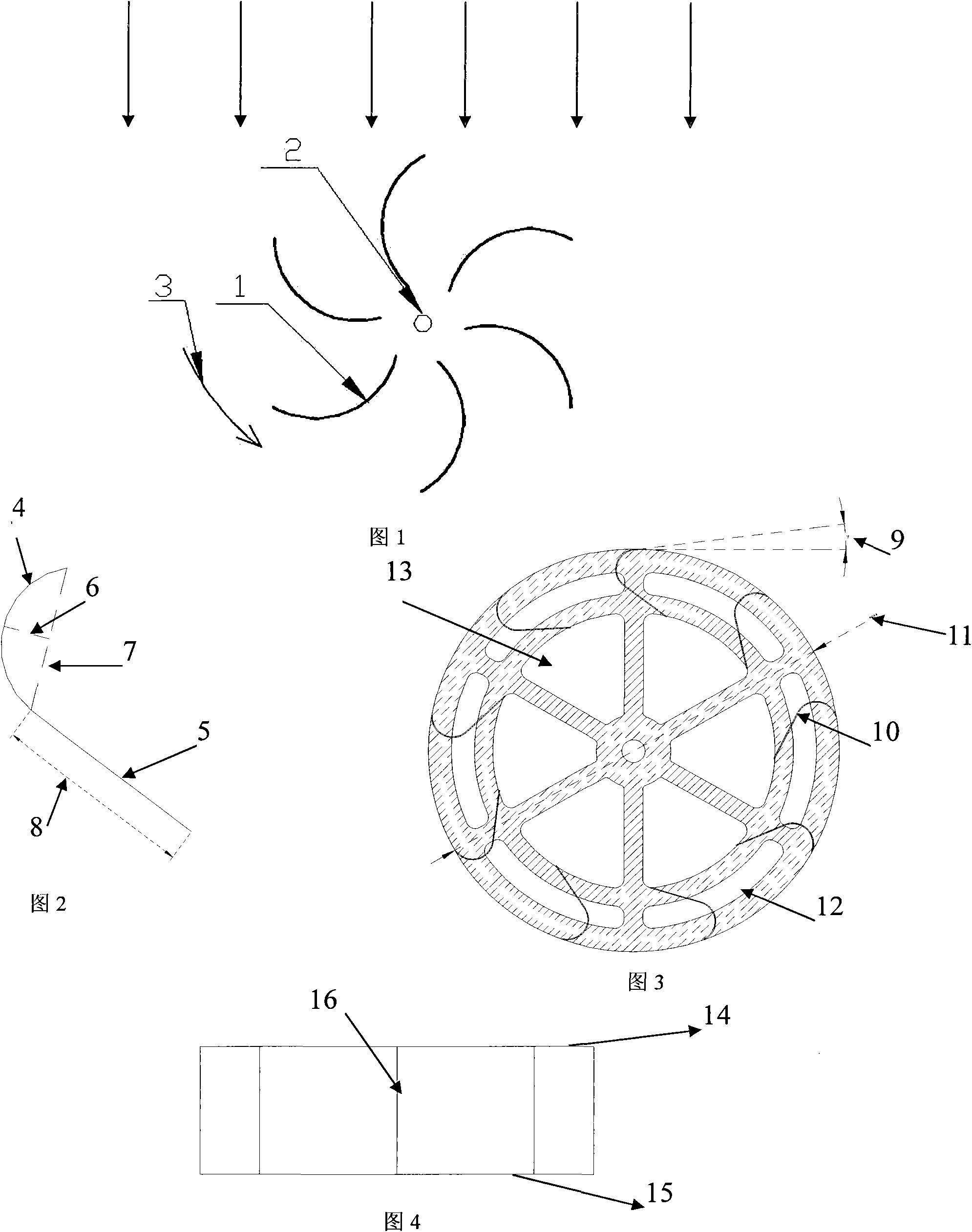

Vertical shaft wind wheel with multi-section combined vanes

A combined, vertical axis technology, applied in the field of wind rotors, can solve the problems of unable to reduce the resistance moment of the effective rotation of the blades and rotors, high investment and operating costs, and wind energy consumption, so as to achieve regular size, improve overall efficiency, The effect of less flow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. However, this embodiment is not intended to limit the present invention, and all similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

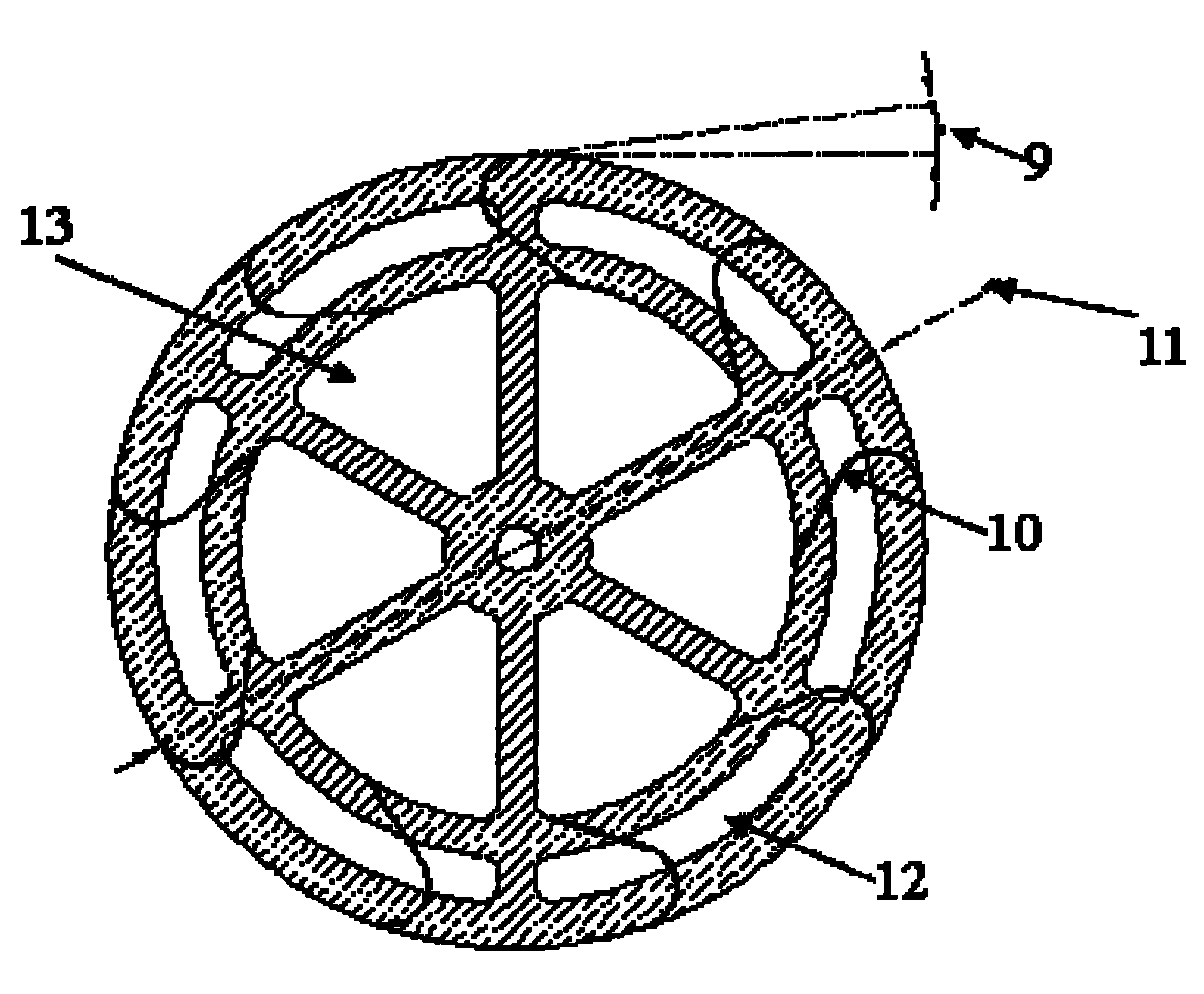

[0019] Such as figure 2 , 3 , Shown in 4: the vertical axis wind wheel with multi-section combined fan blades of the present invention comprises upper and lower cover plates 14,15, rotating shaft 16 and is made up of these two parts of inlet arc section 4 and outlet straight section 5 wind blade 10.

[0020] Nine multi-section combined wind blades 10 are installed between the upper and lower cover plates 14, 15 of the wind wheel, and are arranged at equal intervals along the circumferential direction; the wind blades 10 are straight blades with equal blade heights, and their inlet installation angle 9 is 0°~10°; the outlet straight secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com