Crawler-type traveling power transmission

A traveling power and transmission technology, applied in transmission, fluid transmission, belt/chain/gear, etc., can solve the problems of vibration and shock of transmission system, complex power transmission structure, low transmission efficiency, etc., and achieve good starting performance. , simplifies the shifting operation, the effect of overcoming the ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

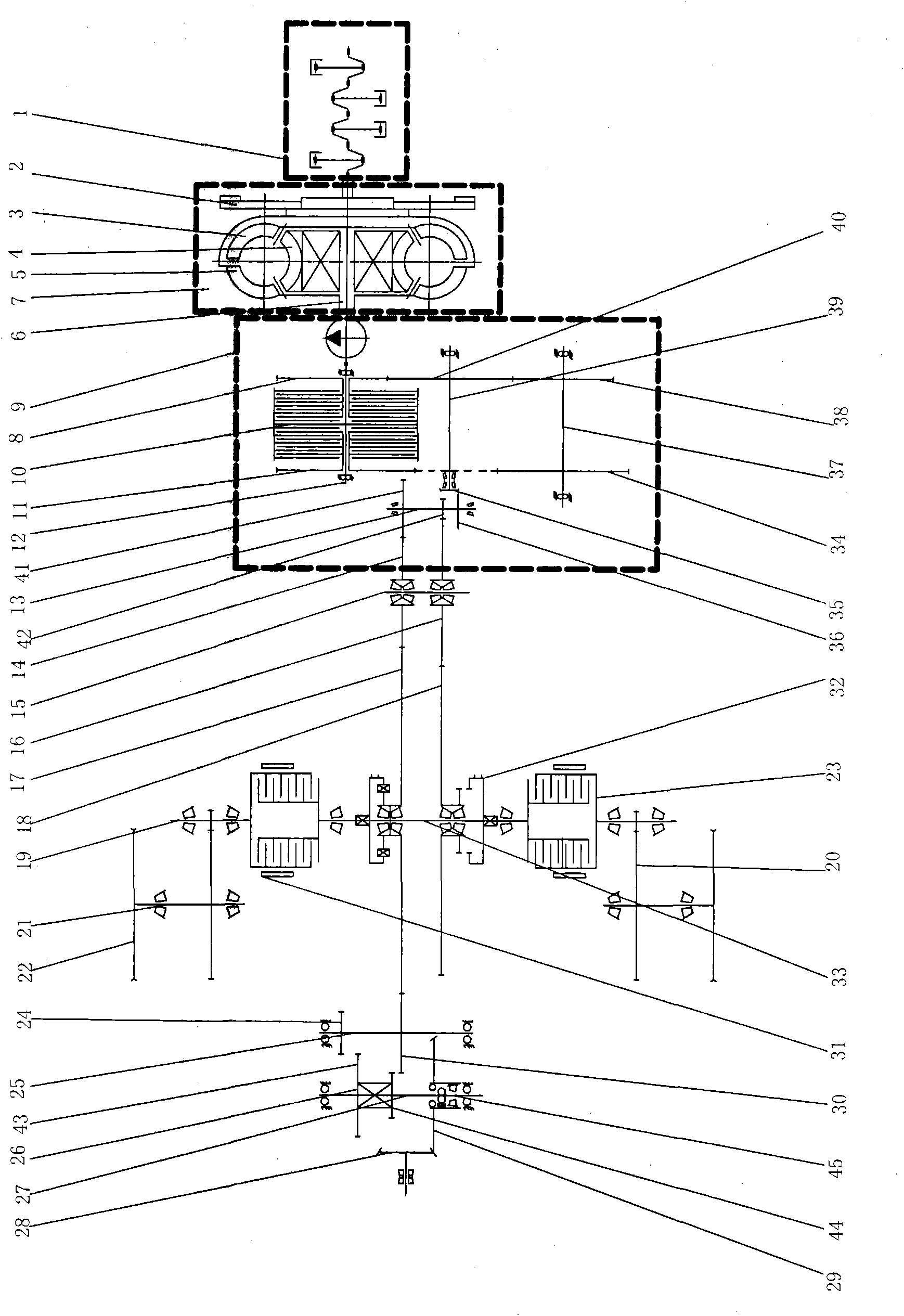

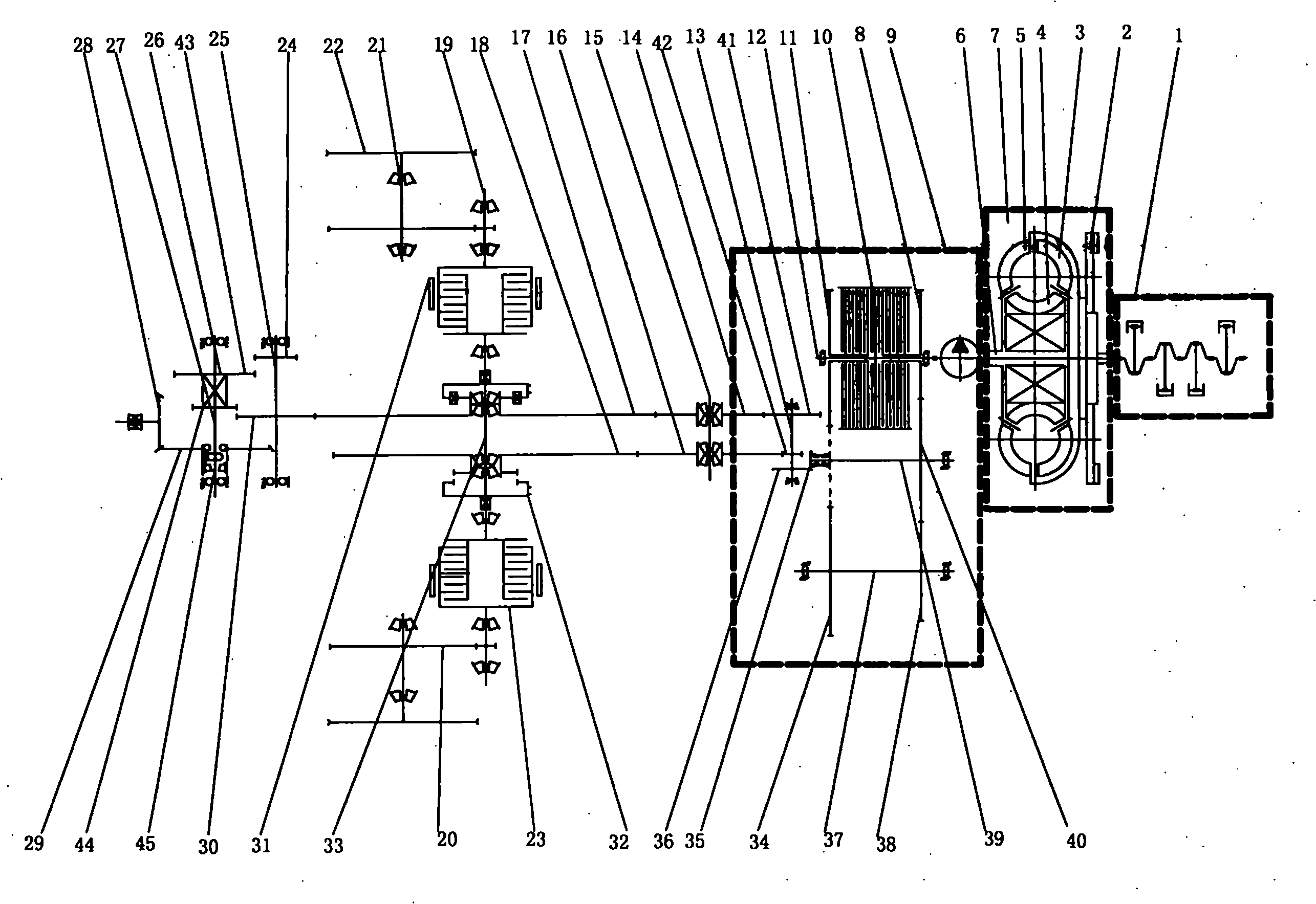

[0015] Refer to attached figure 1 A crawler-type walking power transmission shown includes an engine 1, a hydraulic torque converter 7, a hydraulic gearbox 9 and a power transmission output system, and the hydraulic torque converter 7 is driven by the engine 1 through an elastic connecting plate 2. Drive the pump wheel 5 to rotate, so that the liquid flow flows into the turbine 3 at high speed along the direction of its blades, and drives the turbine 3 to rotate. A hydraulic clutch 10 is arranged on the main input shaft of the hydraulic gearbox 9, and a forward gear 8 and a reverse gear 11 are respectively arranged on both sides of the hydraulic clutch 10, and the forward gear 8 meshes with the output gear 40 fixed on the output shaft 39, The reverse gear 11 meshes with the large idler gear 34 on the idler shaft 37, the small idler 38 on the idler shaft 37 meshes with the output gear 40, the output shaft 39 left end is provided with a bevel gear 35, and the bevel gear 35 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com