Method for measuring appearance of MEMS (Micro Electro Mechanical System) device based on infrared light interference technique

A topography measurement, infrared light technology, applied in measurement devices, instruments, optical devices, etc., can solve problems such as large measurement errors and difficult operation, and achieve the effects of convenient operation, improved processing technology, and reasonable methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

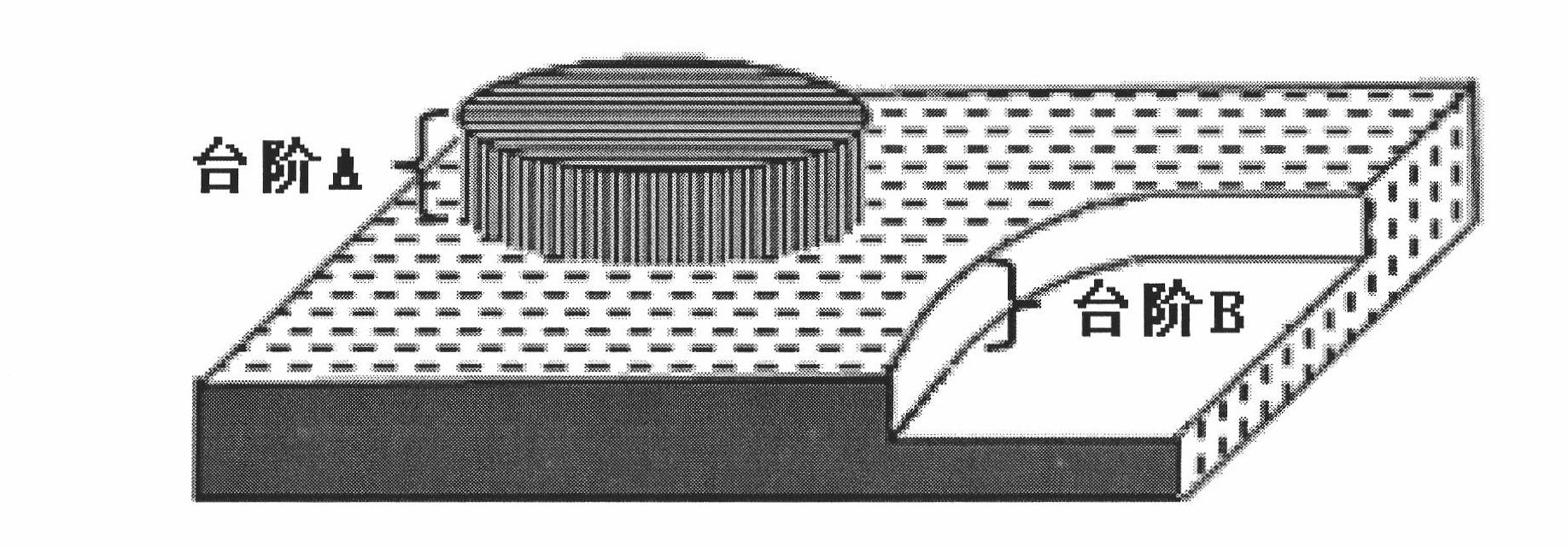

[0039] The MEMS device shape measurement method based on infrared light interference technology is realized in the following steps:

[0040] 1), MEMS device 7 to be tested is prepared before measurement: on the basis of not damaging the topography of the surface to be measured of MEMS device 7 to be measured, non-destructive treatment is carried out on the surface to be measured of MEMS device 7 to be measured to prevent infrared transmission (such as the content of the invention In the verification test, the gold layer 12) that is plated on the surface of the MEMS device to be tested; and after processing, it is placed on the interferometer scanning platform, and the surface to be measured of the MEMS device 7 to be tested is scanned downward toward the interferometer platform;

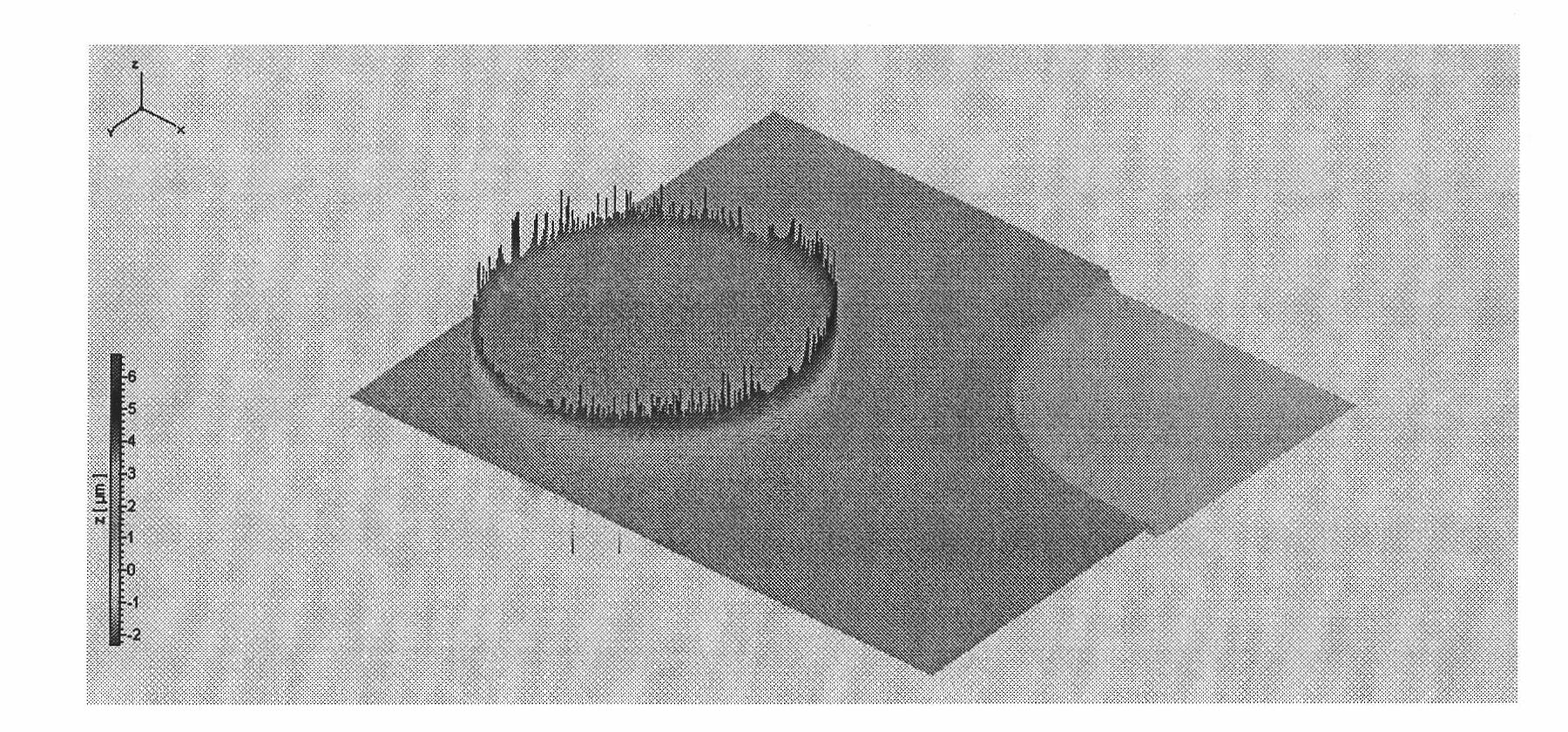

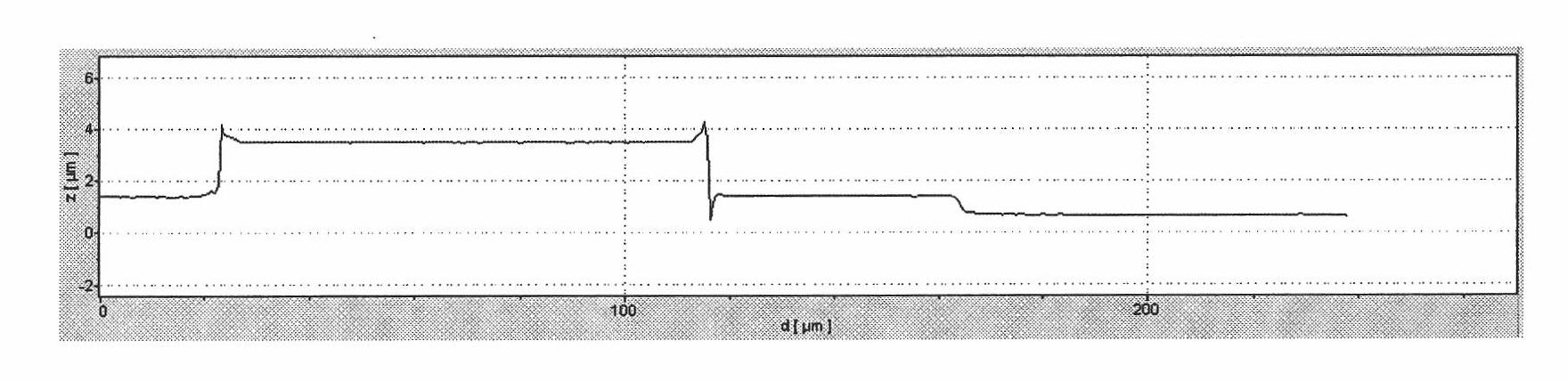

[0041] 2) Use an interferometer to measure the MEMS device to be tested: such as Figure 4 as shown,

[0042] a. Taking the infrared light source 1 as the measurement light source, the infrared lig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

| Half width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com