Cheating prevention electronic weighing apparatus calibrating system and method

A technology of electronic weighing apparatus and calibration system, which is applied in the direction of instrument, induction recording carrier, weighing equipment testing/calibration, etc. It can solve the problems of electronic weighing apparatus cheating, inability to find, lack of weight, etc., and achieve enhanced safety and reliability , prevent cheating, and prevent illegal calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

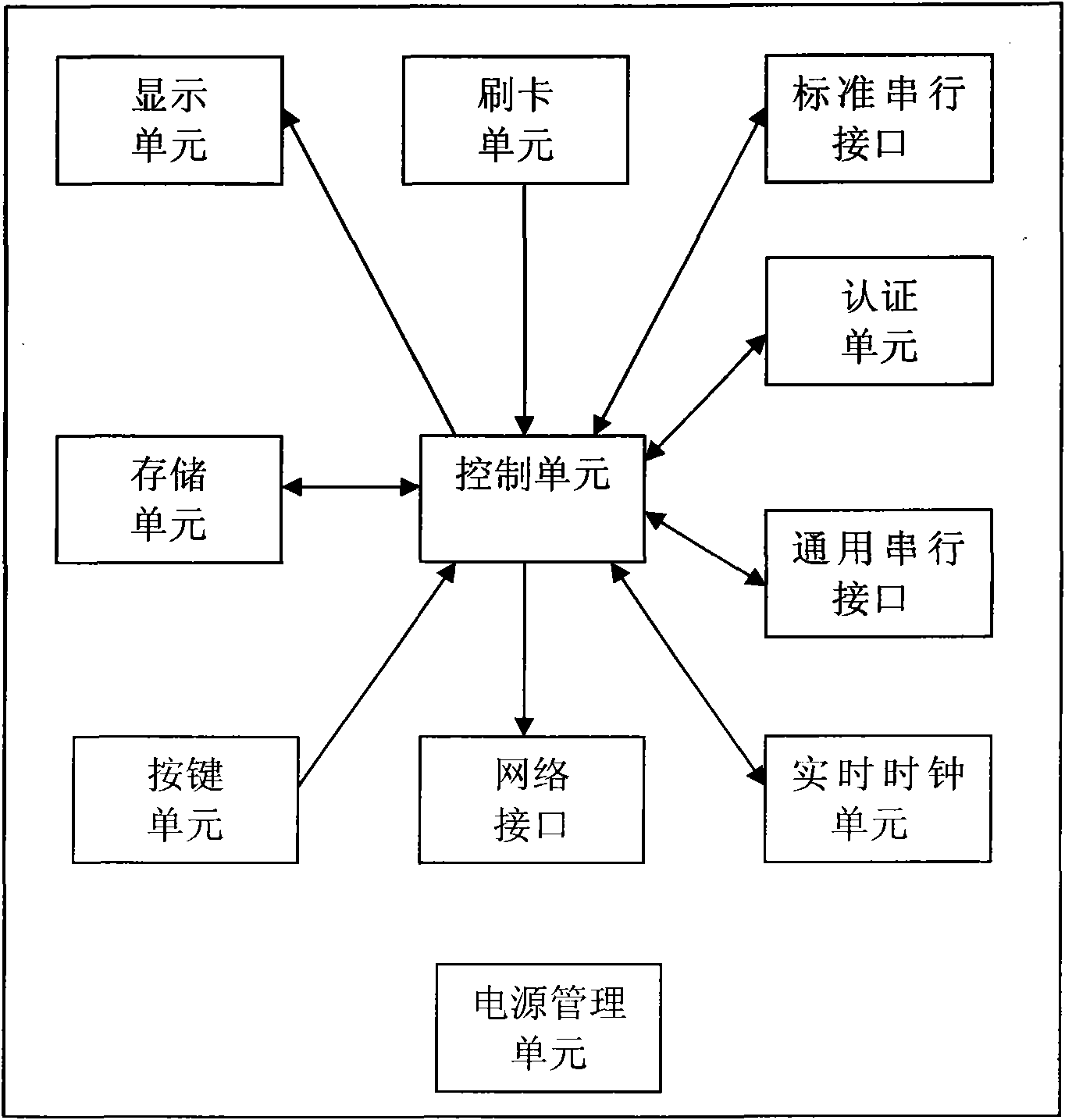

[0026] First introduce the anti-cheating electronic scale calibration device aimed at by the present invention, such as figure 1 As shown, it includes a control unit, a storage unit, a display unit, a key unit and a power management unit, and also includes a card swiping unit, an authentication unit, a universal serial interface and a standard serial interface. The above storage unit, display unit, key unit, swiping card The unit, authentication unit, general serial interface and standard serial interface are directly connected to the control unit in a star shape, and the power management unit is electrically connected to other units and interfaces to manage and provide working power for them. Optionally, the calibration device for electronic weighing instruments further includes a real-time clock unit and a network interface directly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com