Manufacturing of tobacco water content detection standard sample and oven calibration method

A technology of detection standards and production methods, which is applied in the preparation of test samples and the moisture content of materials, can solve the problems of lack of standard basis for oven proofreading, and achieve the effect of broadening the scope of use, maintaining stability and improving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

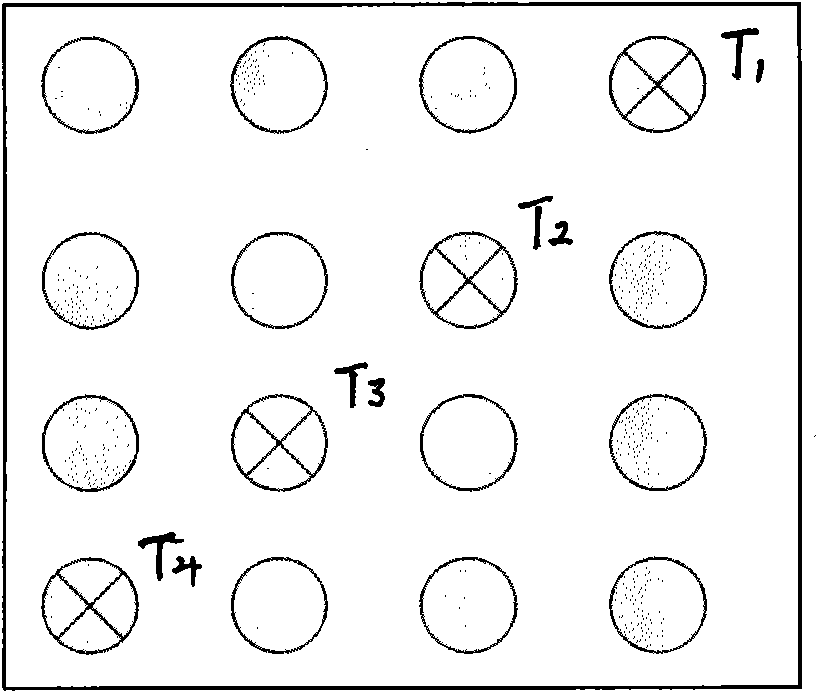

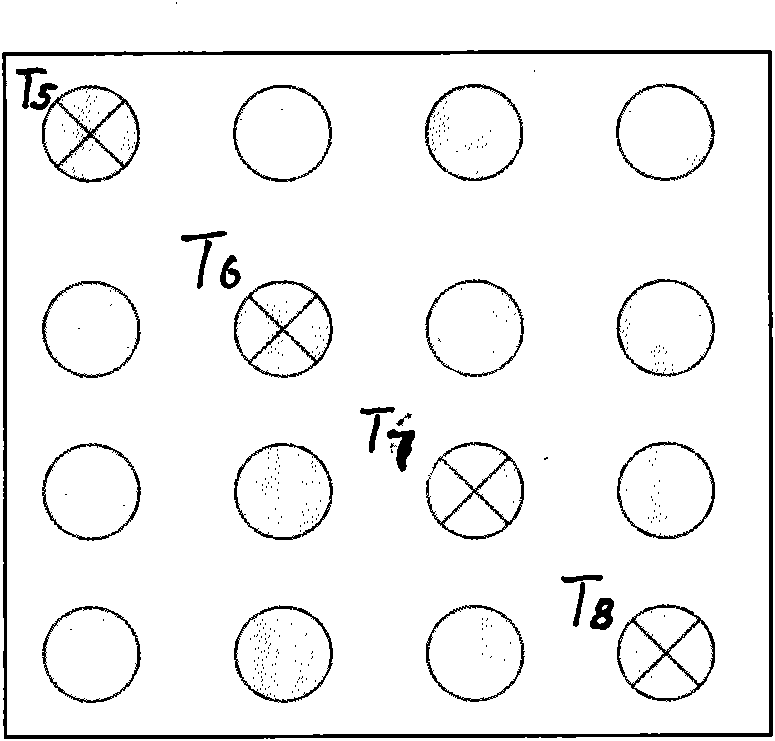

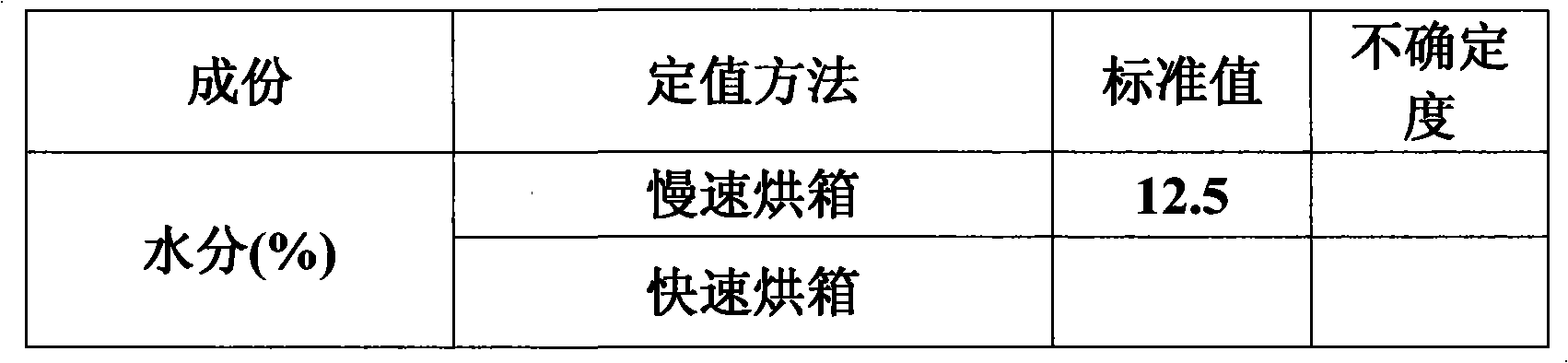

[0021] The present invention adopts the following method to make tobacco moisture detection standard samples: during the production and processing process, when the feeding grade is only the same grade in the same area, take samples in the smoke box at the packing pre-pressing place, remove the impurities from the samples, and separate the stems and leaves , remove the tobacco stems, take the leaves and pulverize them with a cyclone mill, and pass through a 3mm aperture sieve. After the sieve, the particle size below the specified particle size accounts for more than 95%. After mixing evenly with a sample divider, collect and seal it in a sealed container, and vent the air. After seven days to one month, the sample is fully mixed evenly, and the samples are tested separately in all ovens according to the "oven method", and then the mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com