Split gate flash memory and manufacture method thereof

A memory and discrete gate technology, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve problems affecting the performance of flash memory erasing or writing, capacitance reduction, etc., to achieve performance improvement and capacitance increase The effect of large, increased surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] As the density of integrated circuits in existing discrete gate flash memory continues to increase, the surface area of its gate also decreases accordingly, resulting in the constant capacitance between discrete structural units in discrete gate flash memory. become smaller, affecting the performance of flash erase or write.

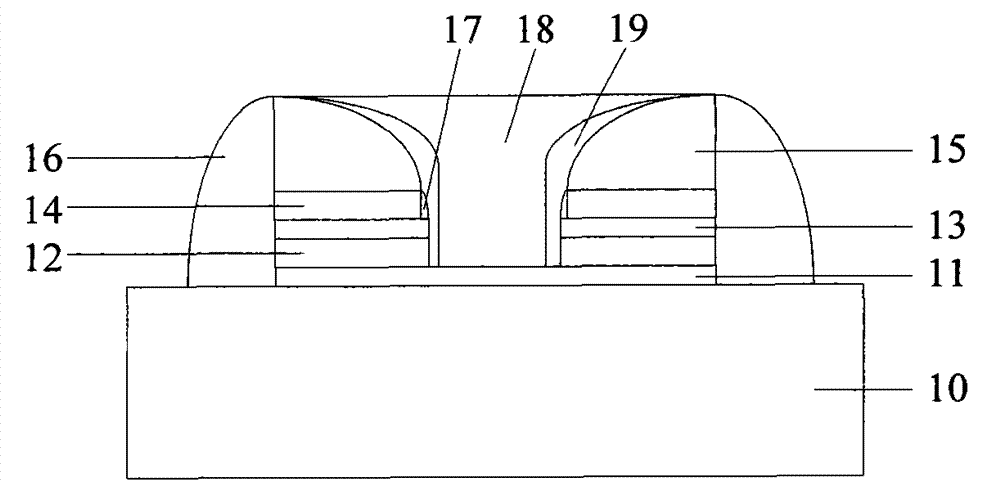

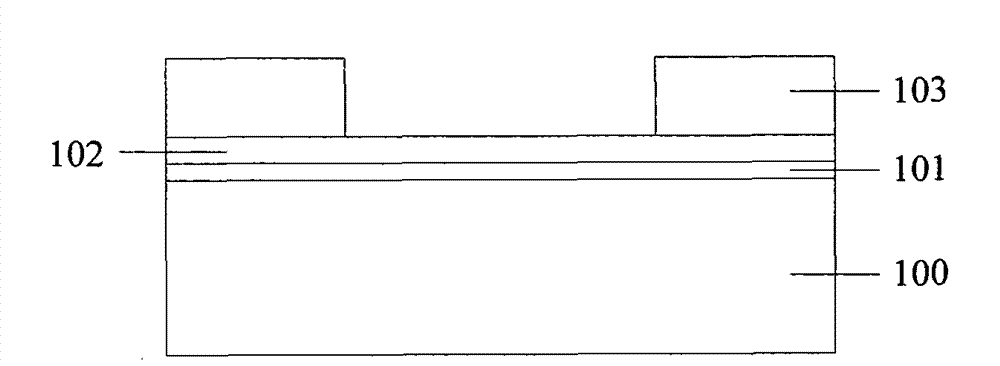

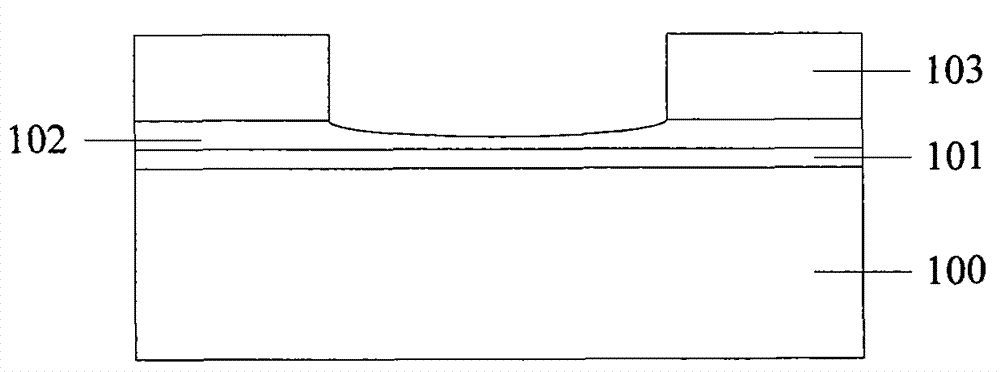

[0013] In order to solve the above-mentioned technical problem, the inventor, through a lot of experiments, found that the problem can be solved by changing the shape of the floating gate. The discrete gate flash memory obtained through the implementation of the present invention includes: a semiconductor substrate; a gate oxide layer located on the surface of the semiconductor substrate, and a discrete structural unit located on the gate oxide layer, and the discrete structural unit has: located on the gate oxide layer The floating gate, the surface of the floating gate is arc-shaped with an inclined angle; the inter-gate dielectric layer on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com