Lamination lay-up system and transfer machine thereof

A transfer machine and stacking technology, applied in the direction of lamination, lamination device, layered products, etc., can solve the problems of high labor intensity, inaccurate alignment, low efficiency, etc., reducing labor intensity and improving production efficiency. , the effect of high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

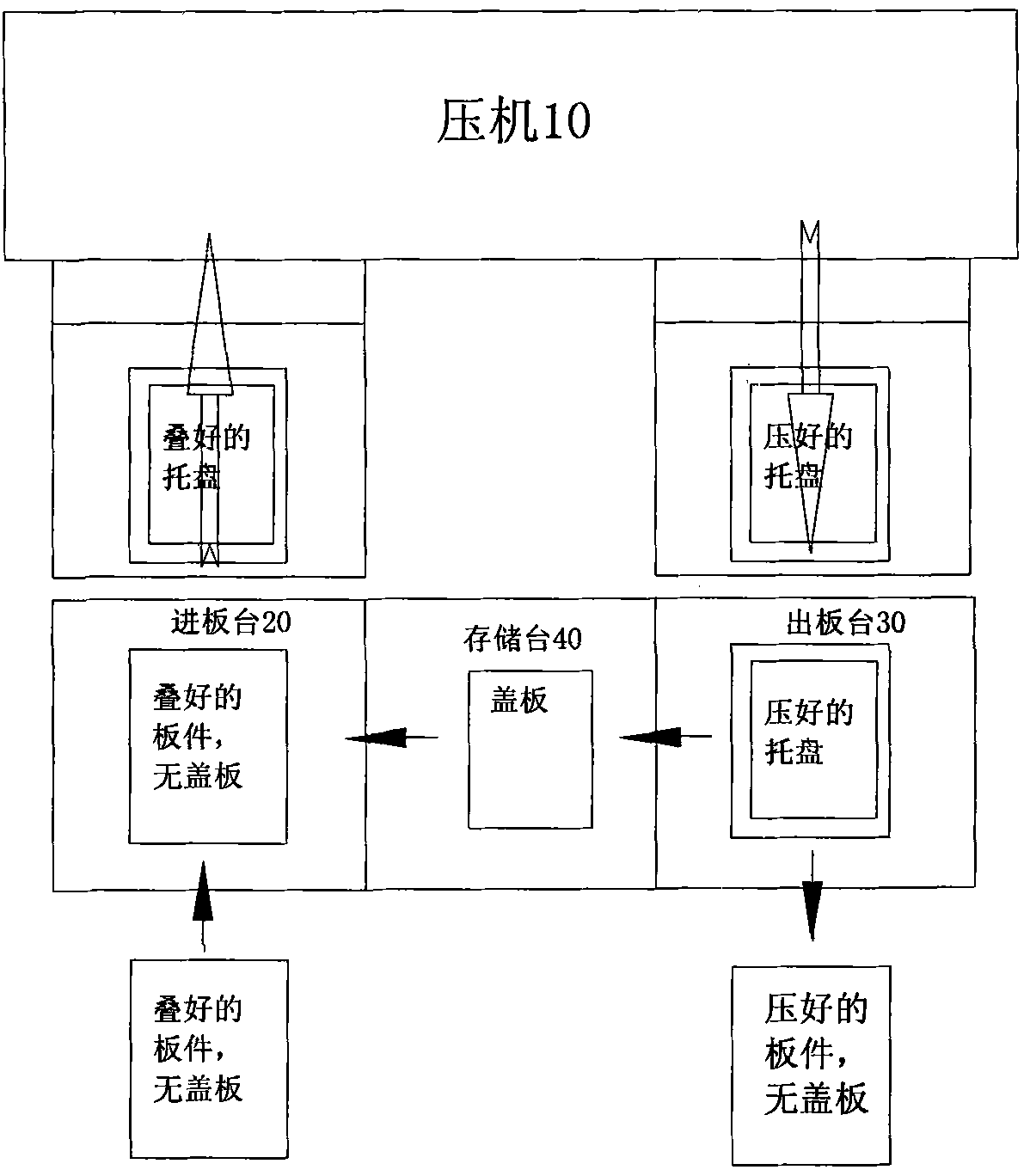

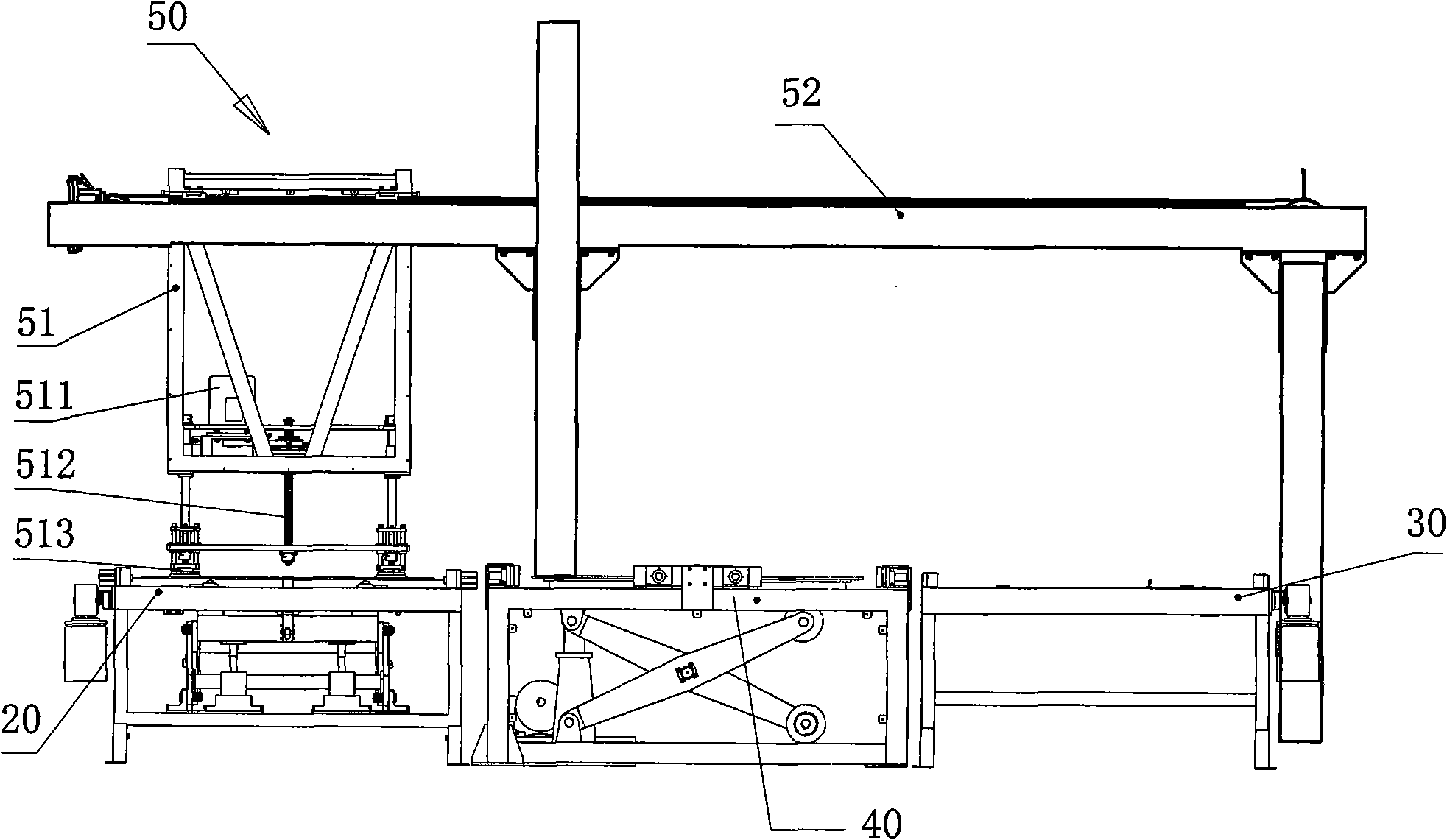

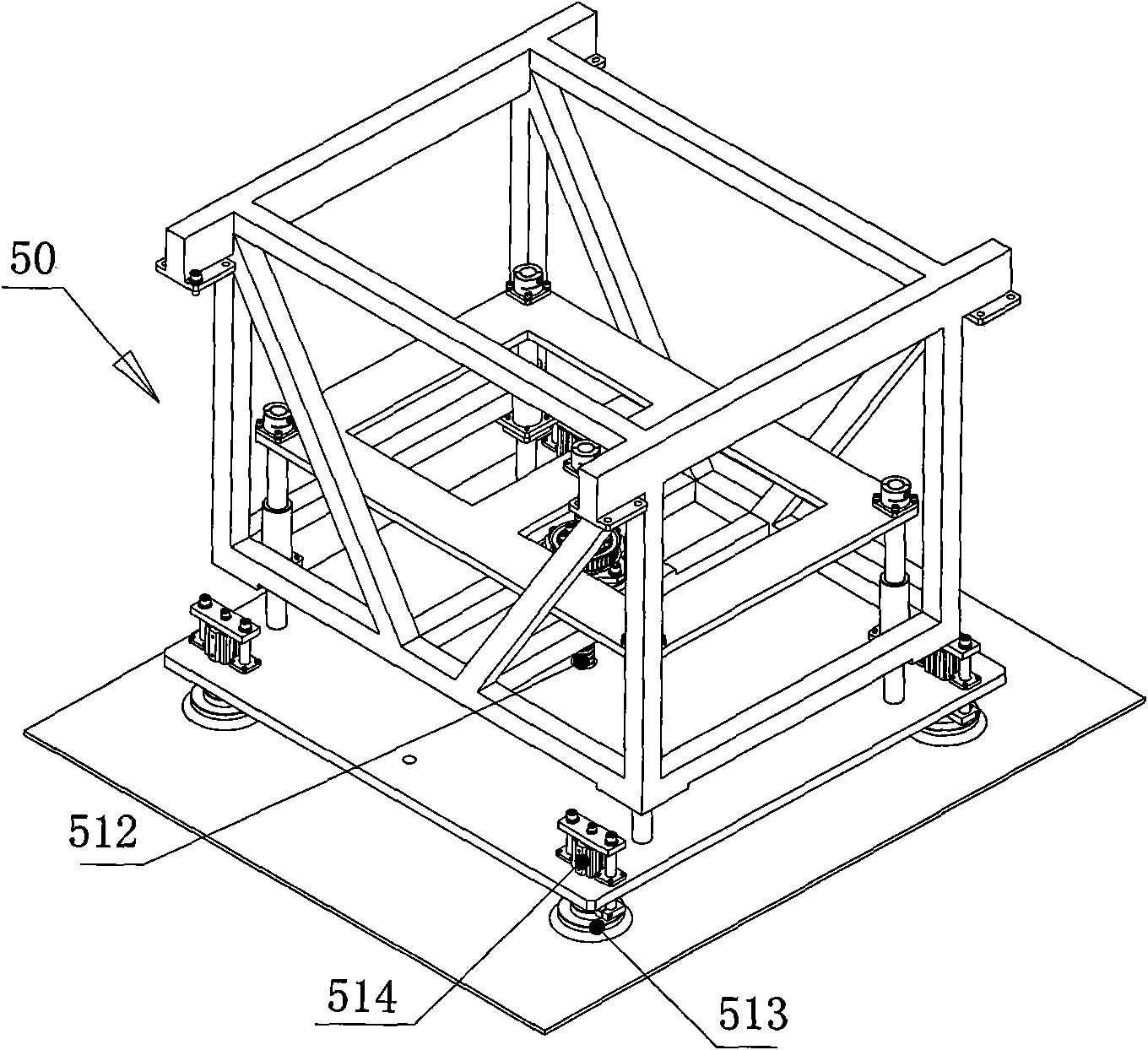

[0040] refer together Figure 1 to Figure 11 , the embodiment of the laminated board system of the present invention includes a press 10, a board feeding table 20 ( Figure 7 , Figure 8 , Figure 9 ), pallet 30 ( Figure 10 , Figure 11 ), storage station 40 ( Figure 5 , Figure 6 ) and transfer machine 50 ( image 3 , Figure 4 );

[0041] refer to figure 1 and figure 2 , the pallet inlet 20 is set adjacent to the feed port of the press 10, and the pallet discharge 30 is set adjacent to the discharge port of the press 10;

[0042] The storage platform 40 is located between the inlet platform 20 and the outlet platform 30;

[0043] The transfer machine 50 includes:

[0044] A pick-and-place device 51 for picking and placing pallet covers between the pallet entry platform 20, the storage platform 40 and the pallet output platform 30;

[0045] A driving device (not shown) that drives the pick-and-place device 51 to move at a fixed point between the pallet entry p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com