Pump bearing arrangement

A bearing device and pump bearing technology, applied in the field of pump bearing devices, can solve the problems of poor radial heat dissipation, insufficient heat dissipation along the radial direction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

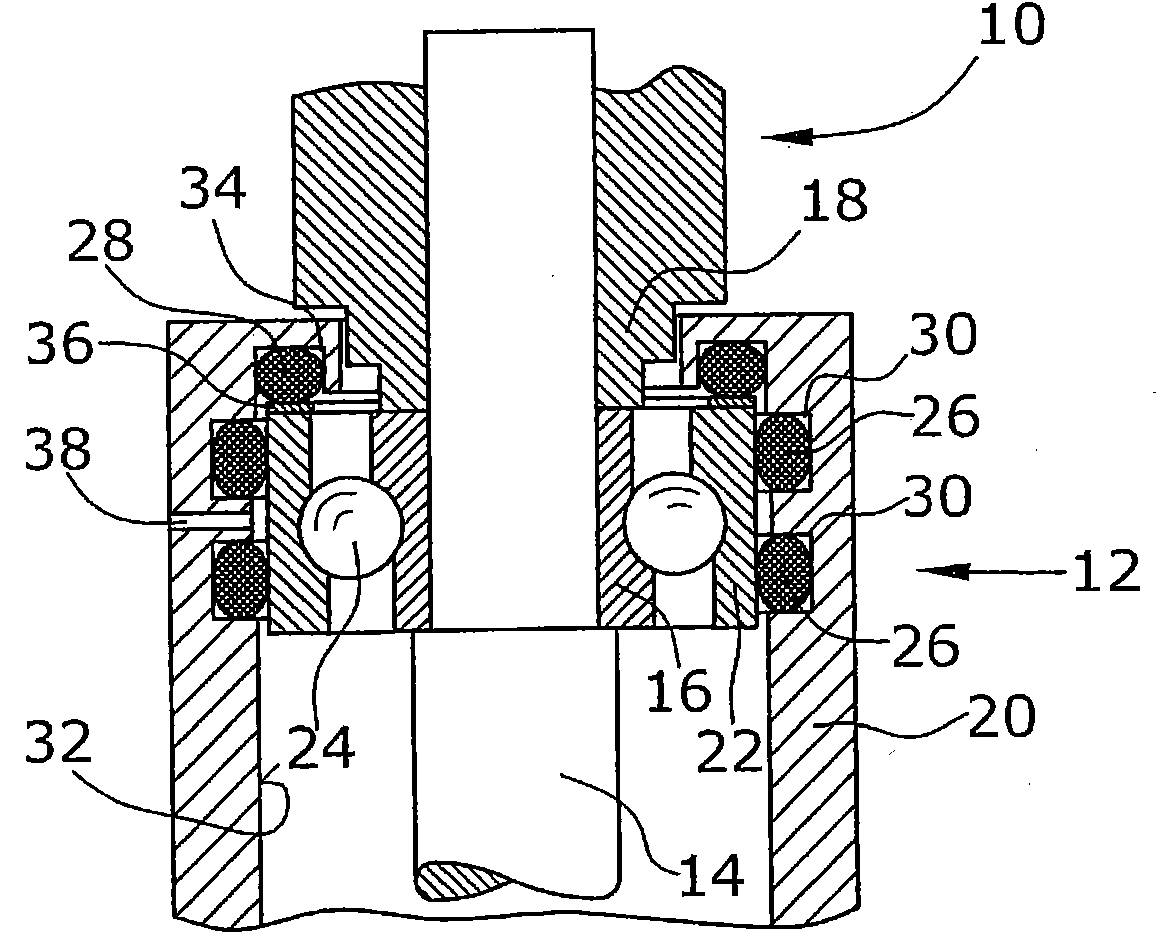

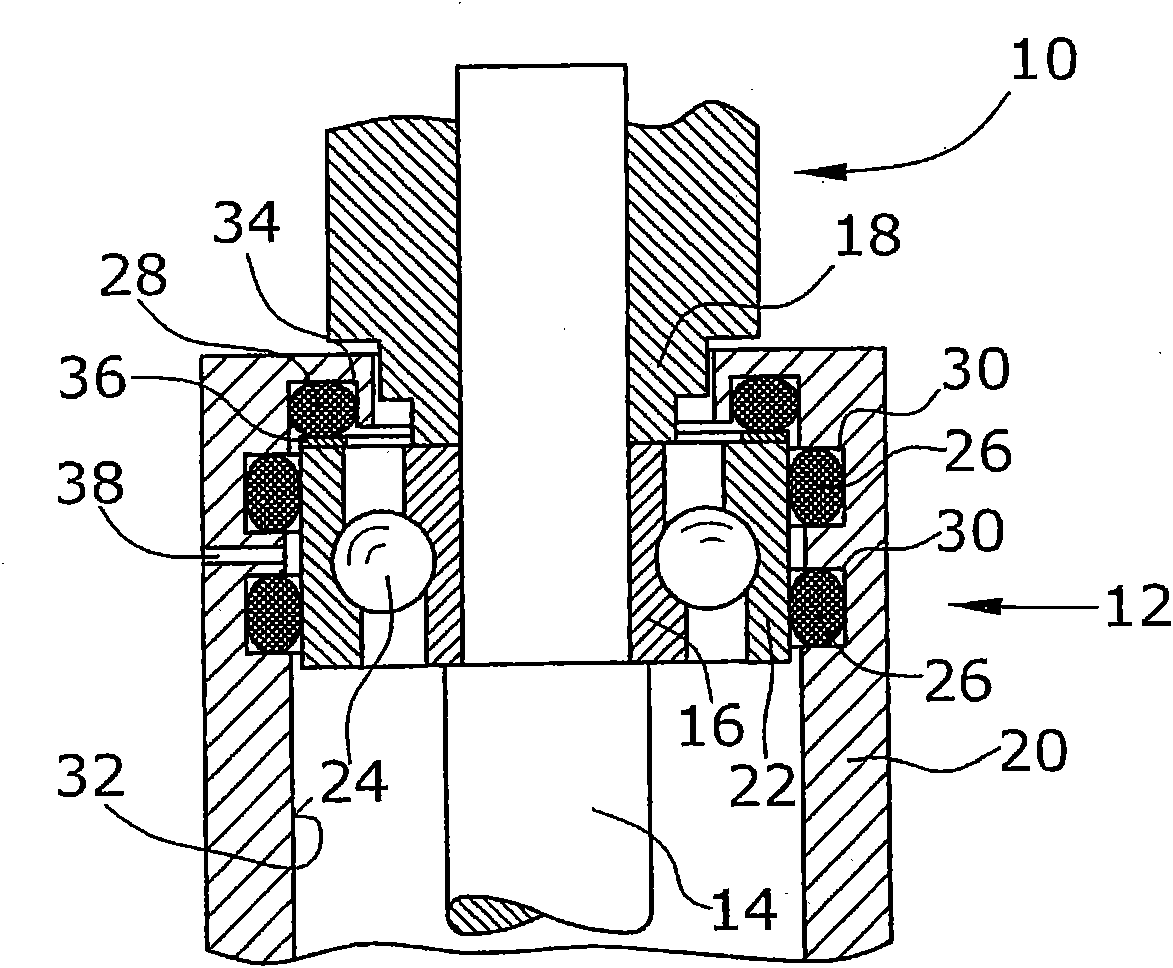

[0019] The figures show a preferred embodiment of the bearing arrangement 12 arranged in an upper position, ie facing the rotor 10 . The rotor 10 is connected for common rotation with a rotor shaft 14 . Arranged for common rotation on the rotor shaft 14 is a grooved ball bearing inner bearing housing 16 held in place by the rotor and stub shaft 18 .

[0020] The upper bearing arrangement 12 is arranged in an axle box 20 which, in the described embodiment, is substantially cylindrical. The outer bearing ring 22 is arranged inside the axle housing 20 . Arranged between the two bearing rings 16 , 22 is a spherical bearing body.

[0021] In a first embodiment, the outer bearing ring 22 is connected to the axlebox 20 by means of two radially vibrating elements 26 formed as elastic O-rings. Further provided is an axial vibration element 28 which is preferably also formed as an elastic O-ring. The two radial vibration elements 26 are respectively arranged in corresponding grooves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com