Multi-specification automatic chopstick painting equipment and method

A technology with multiple specifications and chopsticks, which is applied in coatings and devices for coating liquid on the surface, etc., can solve the problems of large artificial loss of paint, increased labor costs, and unstable quality, so as to improve labor productivity, reduce labor intensity, The effect of stabilizing product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

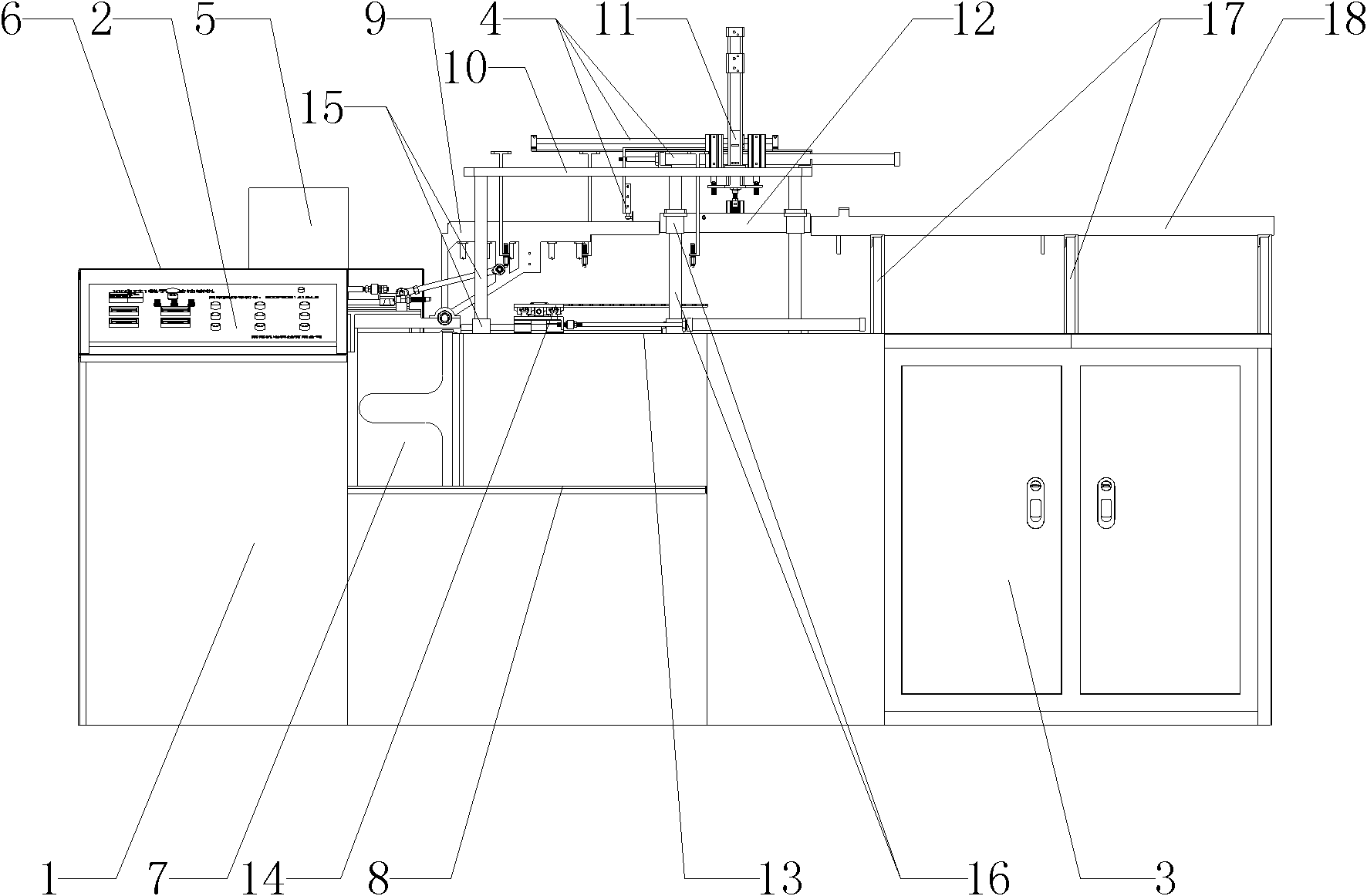

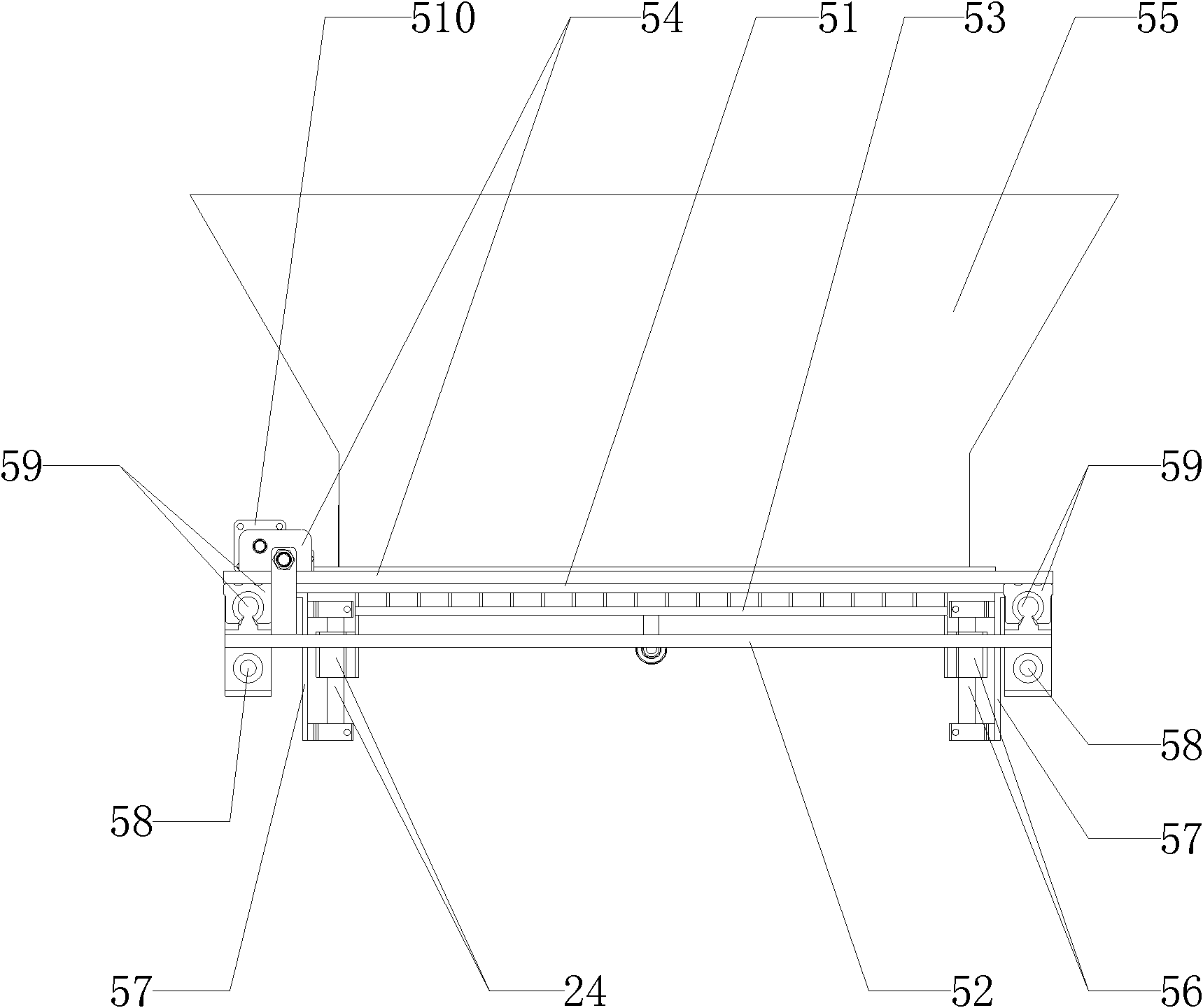

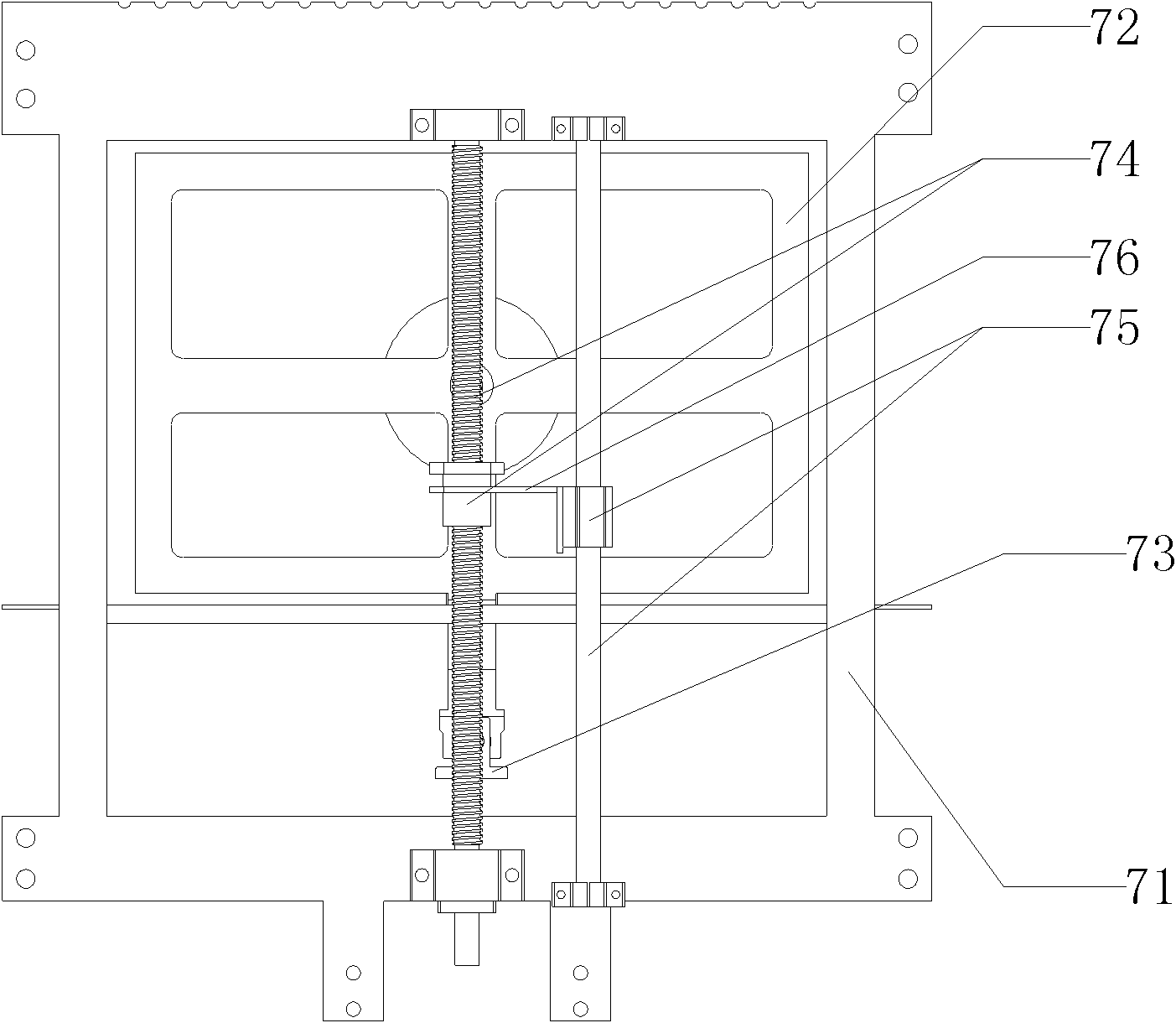

[0018] like Figure 1-6 , 9, a form of the present invention is multi-standard chopsticks automatic painting equipment, including equipment casing 1, electrical control panel 2, pneumatic electrical control cabinet 3, positioning and moving mechanism 4 and row insertion chopsticks mechanism 5, said equipment The top of the shell 1 is provided with a chopsticks preparation table 6 near the left end, and the chopsticks preparation table 6 is provided with a row inserting chopsticks mechanism 5, and the bottom right side of the row inserting chopsticks mechanism 5 is provided with an automatic stepping plate upper mechanism 7, and the automatic stepping The front side of the upper board mechanism 7 middle part is provided with a chopstick board preparation platform 8, and the top of the automatic stepping upper board mechanism 7 is provided with a 90-degree flip manipulator 9 near the right end, and the right side of the 90-degree flip manipulator 9 is provided with a vertical Su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com