Electromagnetic shielding material and preparation method thereof

A technology of electromagnetic shielding materials and raw materials, applied in the fields of magnetic/electric field shielding, electrical components, etc., can solve the problems of high product price, large equipment investment, complex process, etc., and achieve the effect of wide application, low cost and simple process

Active Publication Date: 2010-08-25

顾德阳

View PDF0 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Its purpose is to attenuate electromagnetic radiation, but its equipment investment is large, the process is complicated, and the product price is too high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

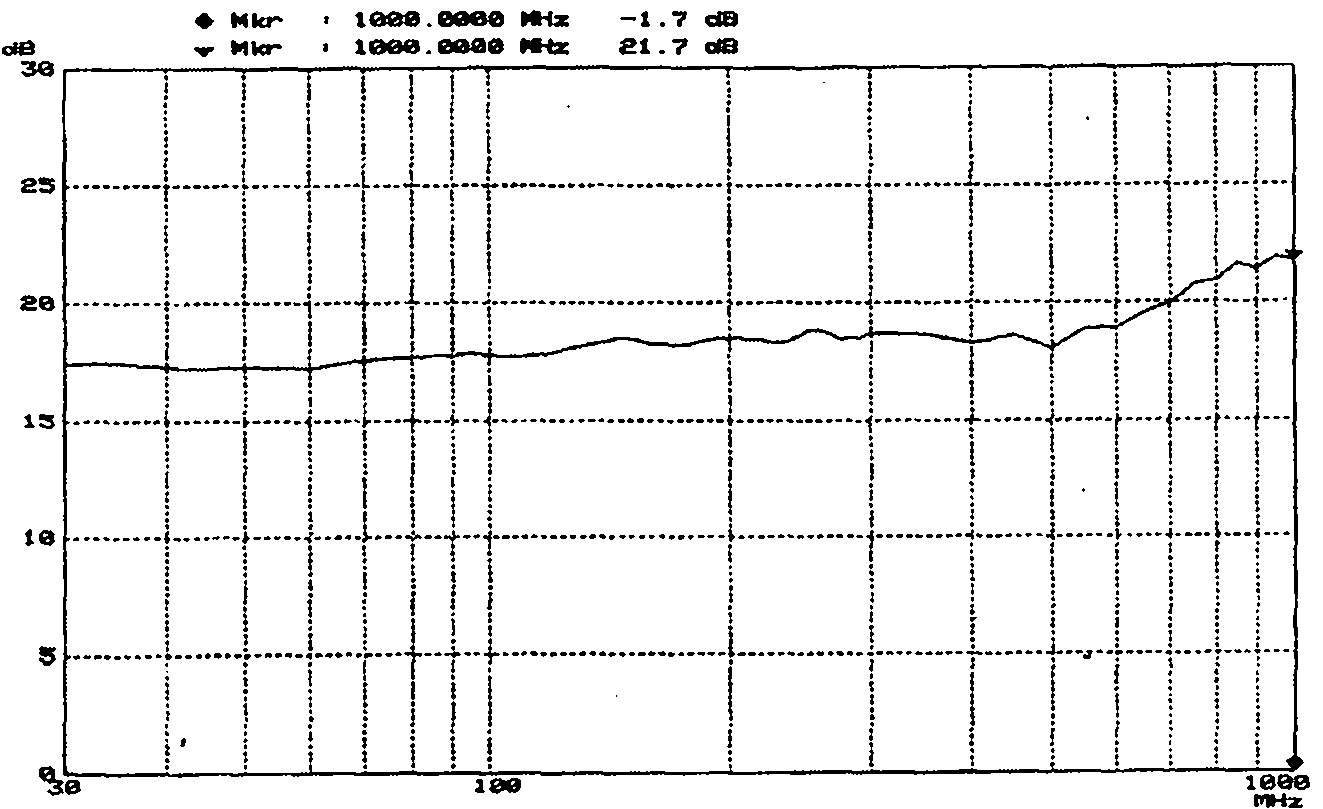

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a chemical material, in particular to an electromagnetic shielding material and a preparation method thereof. The preparation method of the electromagnetic shielding material comprises the following steps of: after mixing, heating and preprocessing ABS plastics and an ABS plasticizer, adding conductive carbon black, magnetic powder and carbon fibre, mixing evenly by a high mixing machine, then delivering into a twin-screw extruder, extruding and granulating so as to prepare the electromagnetic shielding material; and the invention has favorable effect of preventing the radiation of electromagnetic waves and can be applied to the fields of electric power, wireless communication, household appliances and military affairs. The invention has extensive application, simple process and low manufacturing cost and can be recycled.

Description

technical field The invention relates to a chemical material, in particular to an electromagnetic shielding material and a preparation method thereof. Background technique With the improvement of living standards, more and more electrical products have entered the family. These electrical appliances will more or less produce electromagnetic radiation. Electromagnetic radiation exceeding 2 milligauss will cause people to suffer from diseases. Thermal effects, non-thermal effects and cumulative effects on the human body have caused more and more people in a modern sub-health state. The radiation pollution of household appliances should get more and more attention. At present, most of the electromagnetic shielding materials used at home and abroad are made of metal materials. Its purpose is to attenuate electromagnetic radiation, but its equipment investment is large, the process is complicated, and the product price is too high. Contents of the invention The purpose of t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L55/02C08K13/04C08K3/04C08K7/06C08K3/08H05K9/00

Inventor 顾德阳

Owner 顾德阳

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com