Integrated glass heat exchange element by converting solar energy to electrothermal energy

A technology of heat exchange elements and solar energy, which is applied in the field of solar energy applications, can solve the problems of short life, low efficiency, and high cost of photovoltaic cells, and achieve the effects of reducing energy consumption of buildings, reducing node temperature, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

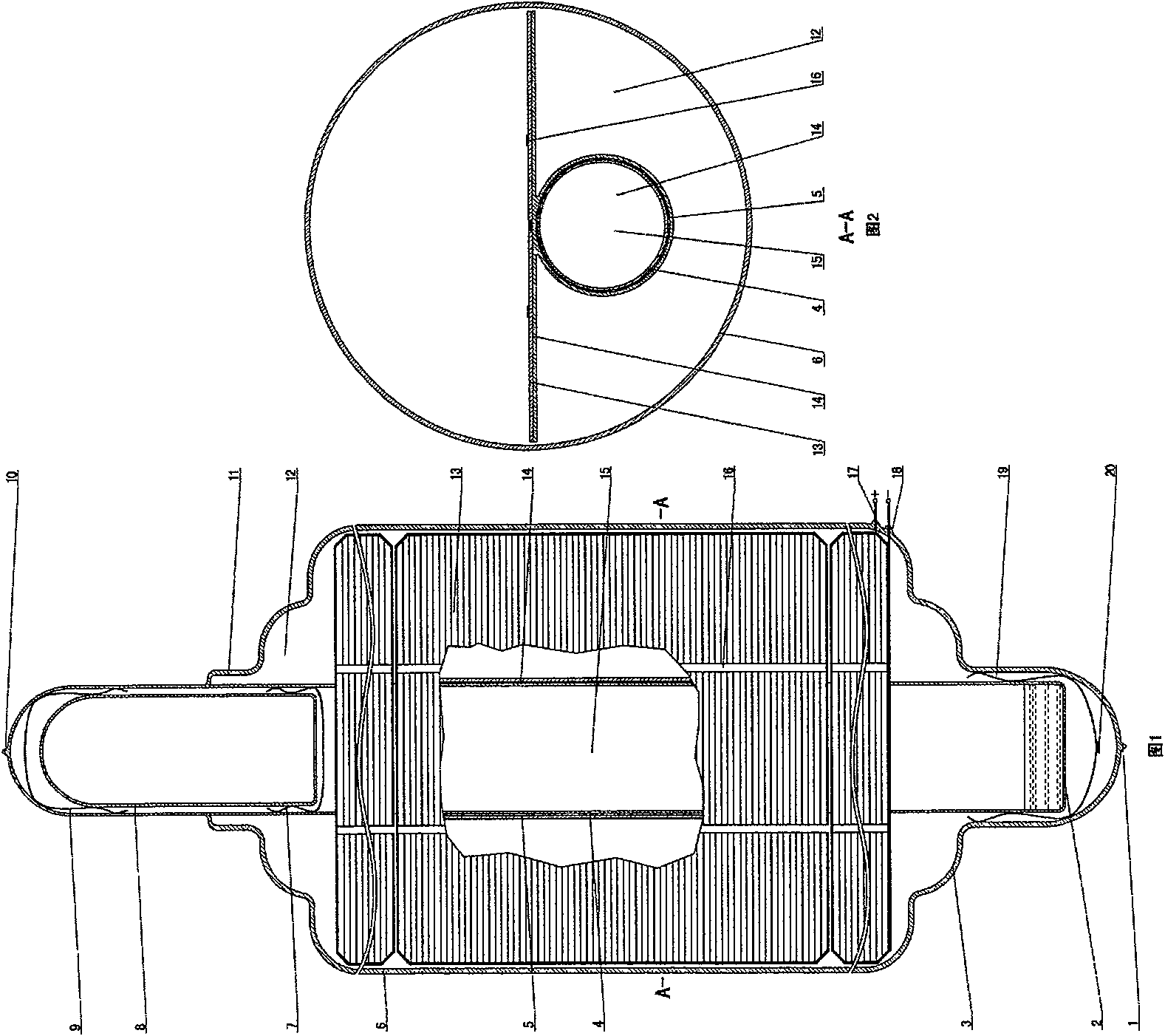

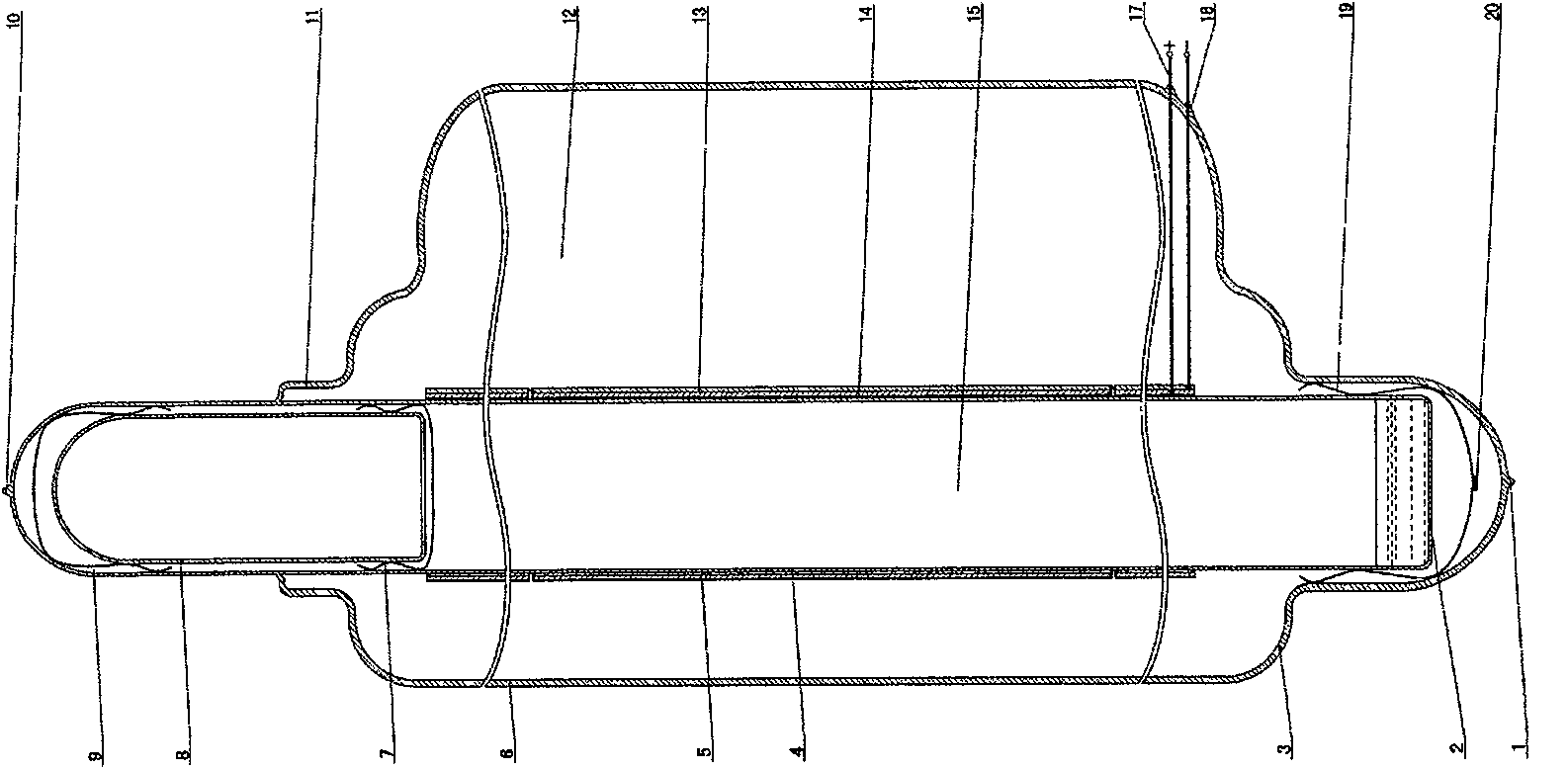

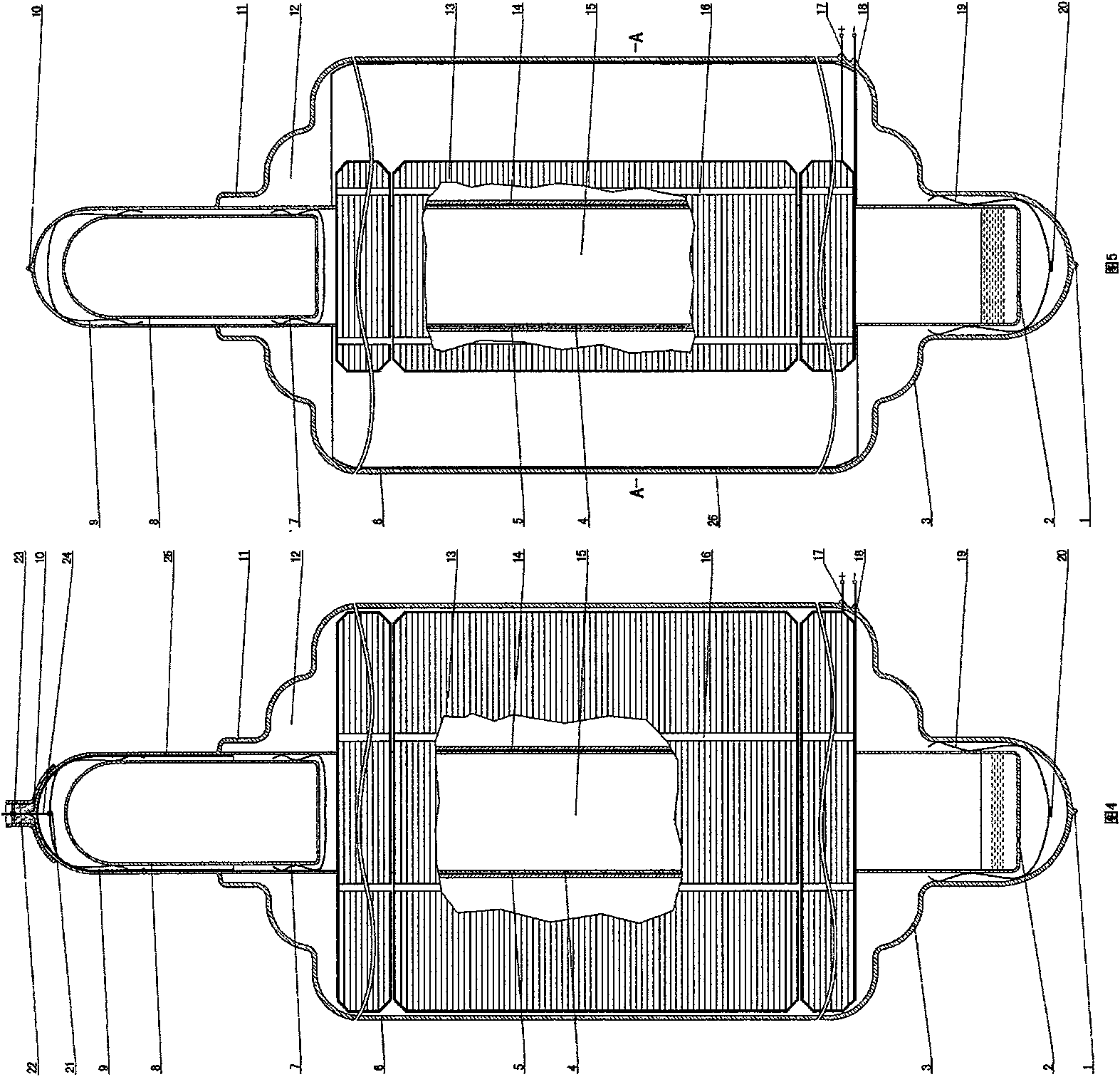

[0080] 1 exhaust pipe seal, 2 glass explosion-proof safety valve, 3 expansion and contraction deformation absorption surface, 4 heat exchange inner glass tube, 5 heat transfer transition filler, 6 light-transmitting outer glass tube, 7 lower metal support bullet, 8 throttling steam Liquid heat exchange device, 9 upper metal support clips, 10 heat-conducting working medium filling and exhaust tailpipe sealing joint, 11 limit installation and connection sealing surface, 12 vacuum ring chamber of glass heat collecting tube, 13 photovoltaic cell, 14 cooling plate, 15 Heat pipe cavity, 16 battery connection wires, 17 glass-sealed metal electrodes, 18 glass-to-metal sealing points, 19 heat exchange inner glass tube support bullets, 20 air getter, 21 static anti-scaling lead-out electrodes, 22 electrode sealing fillers, 23 Installation sealing cap, 24 Electrostatic anti-scaling plug-in electrode, 25 Conductive film, 26 Reflective concentrating mirror, 27 Metal mirror conductive film, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com