Transition metal porous material modified textile adsorbing titanium dioxide and preparation method thereof

A transition metal and porous material technology, applied in textiles and papermaking, light-resistant fibers, fiber treatment, etc., can solve problems such as limited physical adhesion, and achieve good comprehensive functionality, excellent washing resistance, and long-term stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

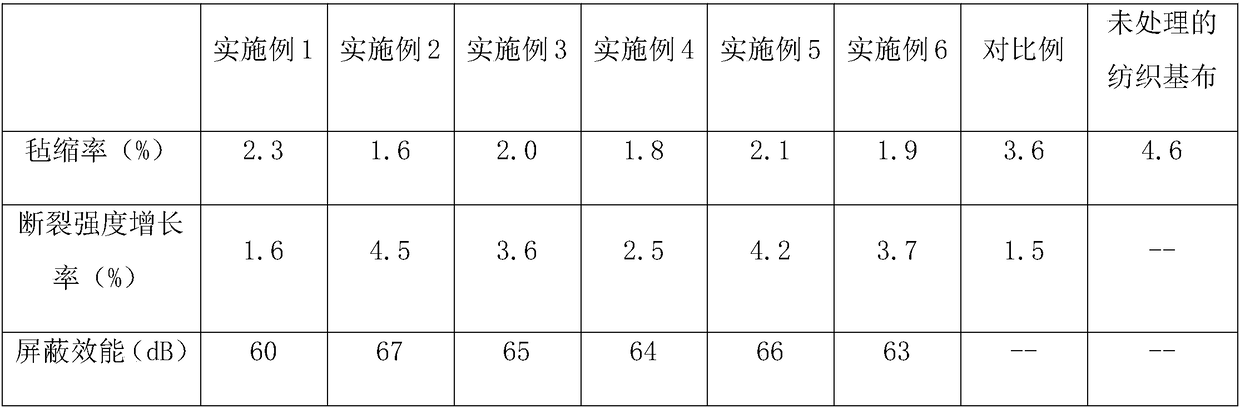

Examples

Embodiment 1

[0025] (1) After zinc powder and chromium powder are mixed and ground, spread one layer in the template, and roll 1h under 1MPa pressure with hydraulic press under room temperature, obtain the transition metal / zinc alloy of sheet layer, wherein, the sheet layer The content of zinc in the transition metal / zinc alloy is 15 wt%.

[0026] (2) Put the sheet transition metal / zinc alloy in a vacuum heating system, under the pressure of 50Pa, raise the temperature to 500°C at 10°C / min, keep it warm for 5min, and evaporate the zinc to obtain a three-dimensional bicontinuous film with a pore size of 100nm transition metal porous materials.

[0027] (3) Add the titanium precursor into the mixed solvent of ethanol and glacial acetic acid and mix evenly, heat and stir at 50°C, add dropwise the ethanol aqueous solution containing hydrochloric acid and stir for 20min, then add the three-dimensional bicontinuous transition metal porous material, continue Stirring for 1 hour and aging for 24 ...

Embodiment 2

[0030] (1) After zinc powder and cobalt powder are mixed and ground, spread one layer in the template, roll 2h under 5MPa pressure with hydraulic press under room temperature, obtain the transition metal / zinc alloy of sheet layer, wherein, the sheet layer The content of zinc in the transition metal / zinc alloy is 25 wt%.

[0031] (2) Put the sheet transition metal / zinc alloy in a vacuum heating system, raise the temperature to 600°C at 15°C / min under a pressure of 100Pa, keep it warm for 120min, and evaporate the zinc to obtain a three-dimensional bicontinuous film with a pore size of 300nm. transition metal porous materials.

[0032] (3) Add the titanium precursor into the mixed solvent of ethanol and glacial acetic acid and mix evenly, heat and stir at 65°C, add dropwise the ethanol aqueous solution containing hydrochloric acid and stir for 30min, then add the three-dimensional bicontinuous transition metal porous material, continue Stir for 2 hours and age for 24 hours to o...

Embodiment 3

[0035] (1) After mixing and grinding zinc powder and palladium and platinum powder with a mass ratio of 1:1, spread a layer in the template, and roll it with a hydraulic press at 3MPa pressure for 1.5h at room temperature to obtain the transition of the sheet Metal / zinc alloy, wherein the content of zinc in the transition metal / zinc alloy of the sheet is 20wt%.

[0036] (2) Put the sheet transition metal / zinc alloy in a vacuum heating system, raise the temperature to 550°C at 12°C / min under a pressure of 80Pa, keep it warm for 30min, and evaporate the zinc to obtain a three-dimensional bicontinuous film with a pore size of 150nm. transition metal porous materials.

[0037] (3) Add the titanium precursor into the mixed solvent of ethanol and glacial acetic acid and mix evenly, heat and stir at 55°C, add dropwise the ethanol aqueous solution containing hydrochloric acid and stir for 25min, then add the three-dimensional bicontinuous transition metal porous material, continue St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com