Combined construction mould for dust-free room air return slab and combined construction method thereof

A construction method and combined technology, which is applied to the preparation of floor slabs, formwork/formwork/work frames, and building components on site, can solve the problems of increasing costs, not being environmentally friendly, and not being able to be reused. The effect of lowering operating costs, increasing project quality, and reducing congestion and laborious manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

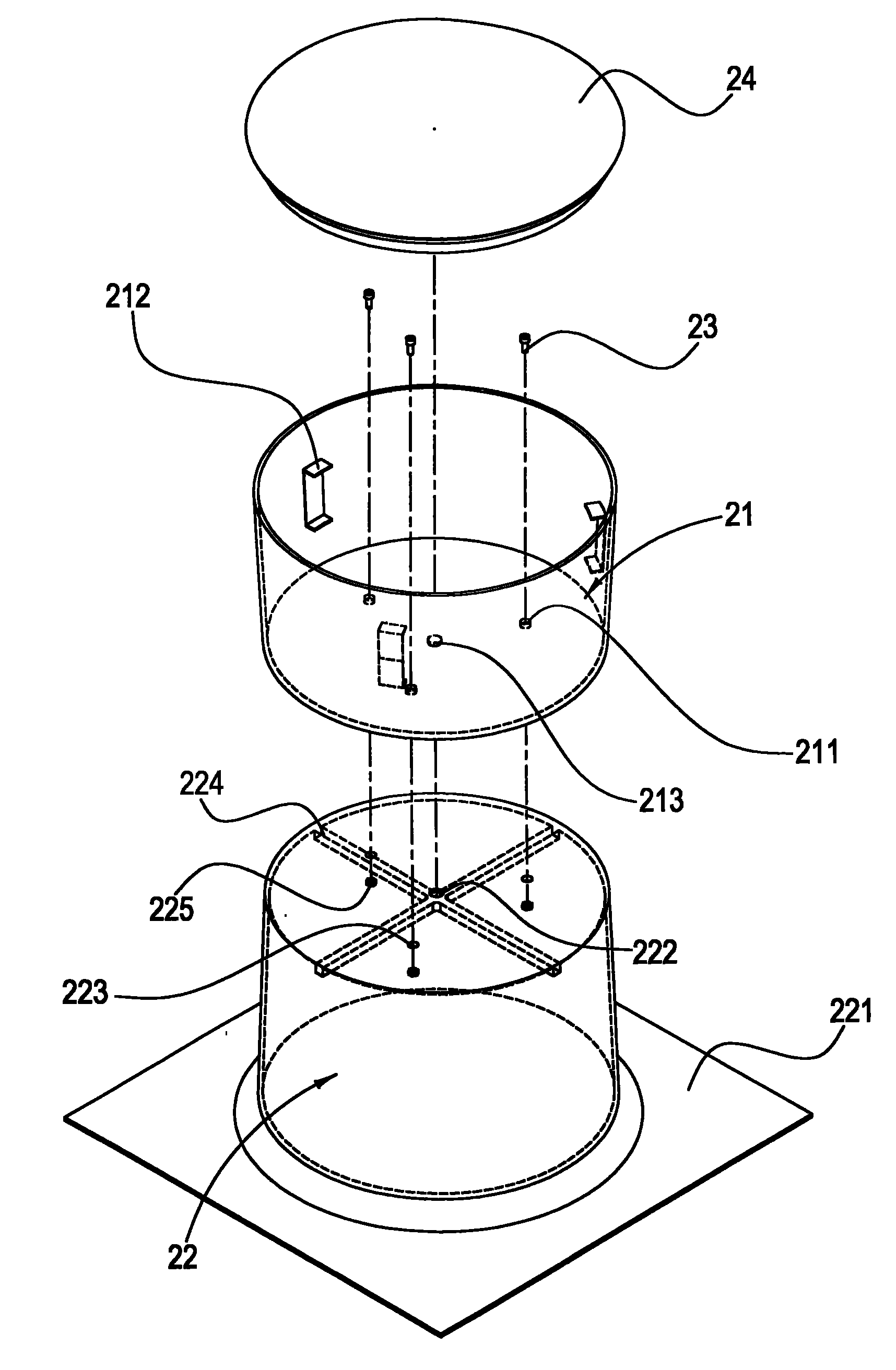

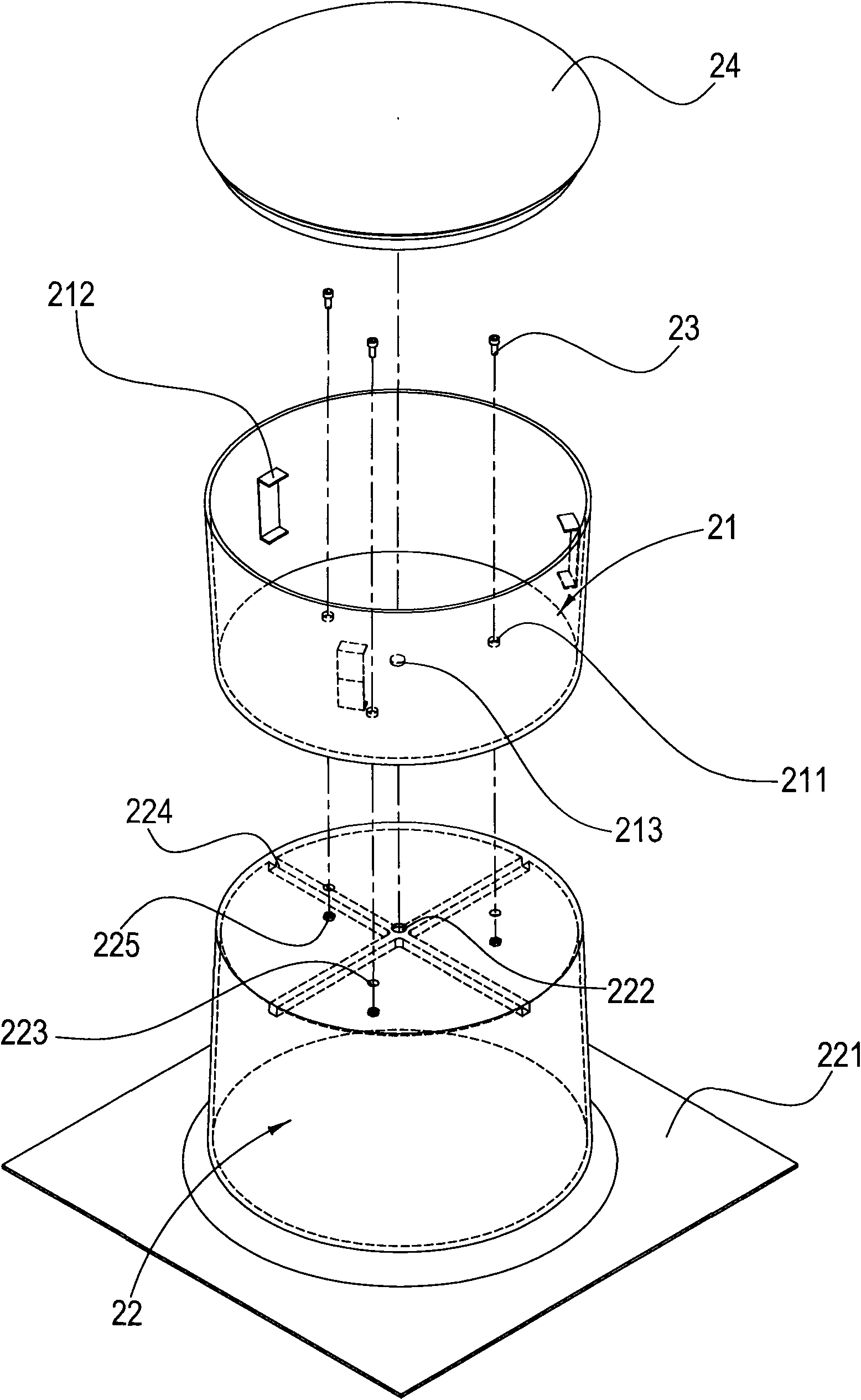

[0033] Please refer to Fig. 2A and Fig. 2B, which are the structural diagrams of the combined construction mold for the return air floor of the clean room of the present invention, mainly including:

[0034] An upper mold 21 is in the shape of a cylindrical barrel, with a hole 211 at the bottom, a flange 213 at the center of the outer layer of the bottom, and a force carrying handle 212 on the inner cylindrical surface, and a The cover plate 24 is used to prevent concrete from pouring in accidentally during the grouting operation, wherein the locking member 23 can be a screw;

[0035] The lower part of the mold 22 is in the shape of a cylindrical barrel, with a base 221 extending from the edge of the opening, and a reinforcing rib 224 on the top of the inner layer, and a hole 223 and a blind hole 222 on the top of the outer layer, wherein the reinforcing rib 224 It can help to increase the strength of the structure, and a nut 225 can be arranged in the hole 223;

[0036] Duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com