Method for preparing ethanol sensitive material with fine graded porous structure

An ethanol-sensitive, hierarchically porous technology, applied in the field of sensing materials, can solve problems such as loose connection, limited selective recognition stability, and cumbersome preparation process, so as to ensure safety and stability, ensure people's life safety, and simple process The effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

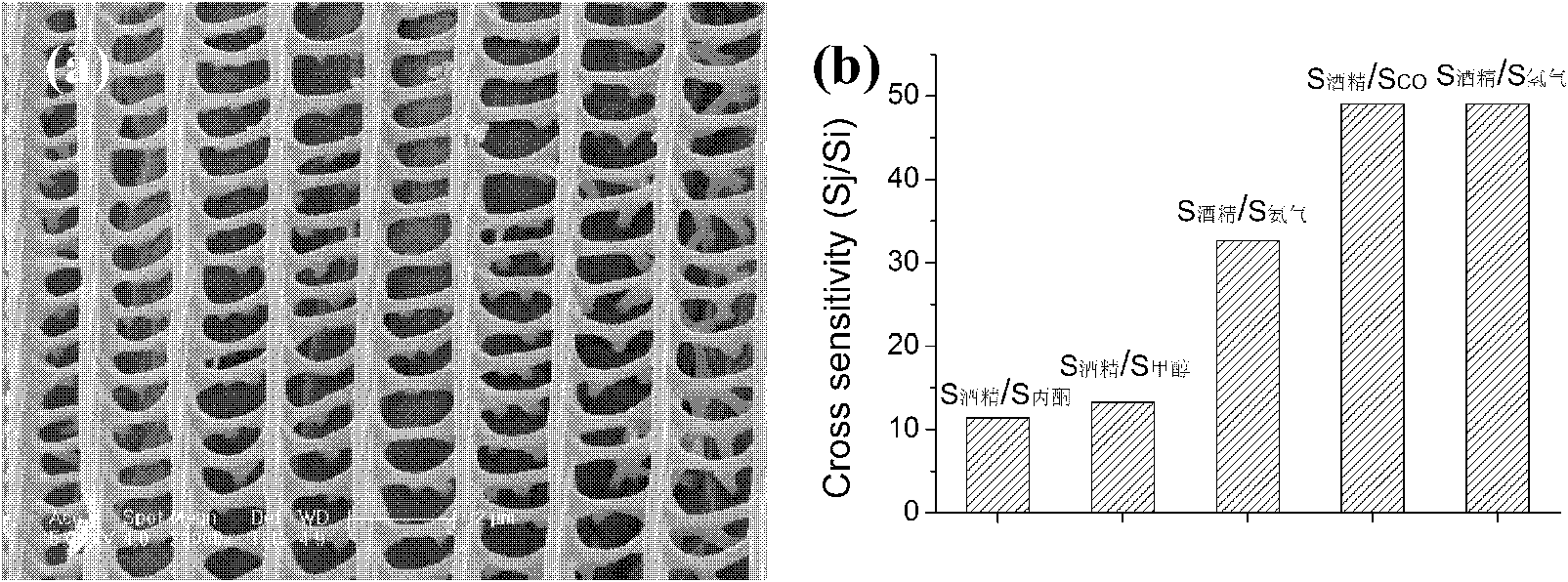

Embodiment 1

[0016] Add 2M HNO to tin metal powder 3 Stir in the solution until the solution turns light yellow, and filter to obtain the impregnation solution. Rinse the butterfly wings in absolute ethanol. Before the absolute alcohol is completely dried and volatilized, when the color of the butterfly wings changes from dark green to blue-purple, quickly place the treated butterfly wings on the tin Soak in the salt dipping solution for 24 hours, take out the butterfly wings, wash them with alcohol, put them in a drying oven at 60°C for drying, and then put them in an oxidation furnace for burning treatment, and raise the temperature to 550°C at a heating rate of 2°C / min. After 1.5 hours of heat preservation, it was naturally cooled to room temperature, and the white flake product obtained was rutile tin dioxide (JCPD41-1445) with finely graded porous structure in butterfly wing shape. Its grain size is about 7.0nm, and its specific surface area and porosity are 51m 2 g -1 and 0.14cm ...

Embodiment 2

[0018] Add 2M HNO to tin metal powder 3 Stir in the solution until the solution turns light yellow, and filter to obtain the impregnation solution. Rinse the butterfly wings in absolute ethanol. Before the absolute alcohol is completely dried and volatilized, when the color of the butterfly wings changes from dark green to blue-purple, quickly place the treated butterfly wings on the tin Soak in the salt dipping solution for 18 hours, take out the butterfly wings, wash them with alcohol, put them in a drying oven at 60°C for drying, and then put them in an oxidation furnace for burning treatment, and raise the temperature to 550°C at a heating rate of 2°C / min. After 1.5 hours of heat preservation, it was naturally cooled to room temperature, and the white flake product obtained was rutile tin dioxide (JCPD41-1445) with finely graded porous structure in butterfly wing shape. Its grain size is about 7.0nm, and its specific surface area and porosity are 50m 2 g -1 and 0.15cm ...

Embodiment 3

[0020] Add 2M HNO to tin metal powder 3 Stir in the solution until the solution turns light yellow, and filter to obtain the impregnation solution. Rinse the butterfly wings in absolute ethanol. Before the absolute alcohol is completely dried and volatilized, when the color of the butterfly wings changes from dark green to blue-purple, quickly place the treated butterfly wings on the tin Soak in the salt dipping solution for 14 hours, take out the butterfly wings, wash them with alcohol, put them in a drying oven at 60°C for drying, and then put them in an oxidation furnace for burning treatment, and raise the temperature to 550°C at a heating rate of 2°C / min. After 1.5 hours of heat preservation, it was naturally cooled to room temperature, and the white flake product obtained was rutile tin dioxide (JCPD41-1445) with finely graded porous structure in butterfly wing shape. Its grain size is about 7.0nm, and its specific surface area and porosity are 56m 2 g -1 and 0.16cm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com