Method for detecting early-stage mechanical property degradation of material by utilizing nolinear rayleigh wave

A nonlinear and Rayleigh wave technology, applied in material analysis using sonic emission technology, solid analysis using sonic/ultrasonic/infrasonic waves, etc. Improve the efficiency of transmission and reception, facilitate collection, and spread the effect of long distances

Inactive Publication Date: 2010-08-25

BEIJING UNIV OF TECH

View PDF0 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Most of the current research is to use the longitudinal wave nonlinearity to measure the ultrasonic nonlinear coefficient of the material, and it is impossible to detect the degradation of the mechanical properties of the plate structure.

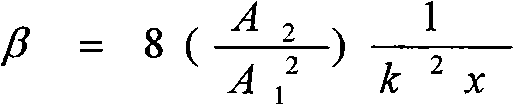

In addition, since the nonlinear coefficient β that characterizes the magnitude of the nonlinear effect of the material is very small, it is easily overwhelmed by the nonlinearity brought by the detection instrument, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

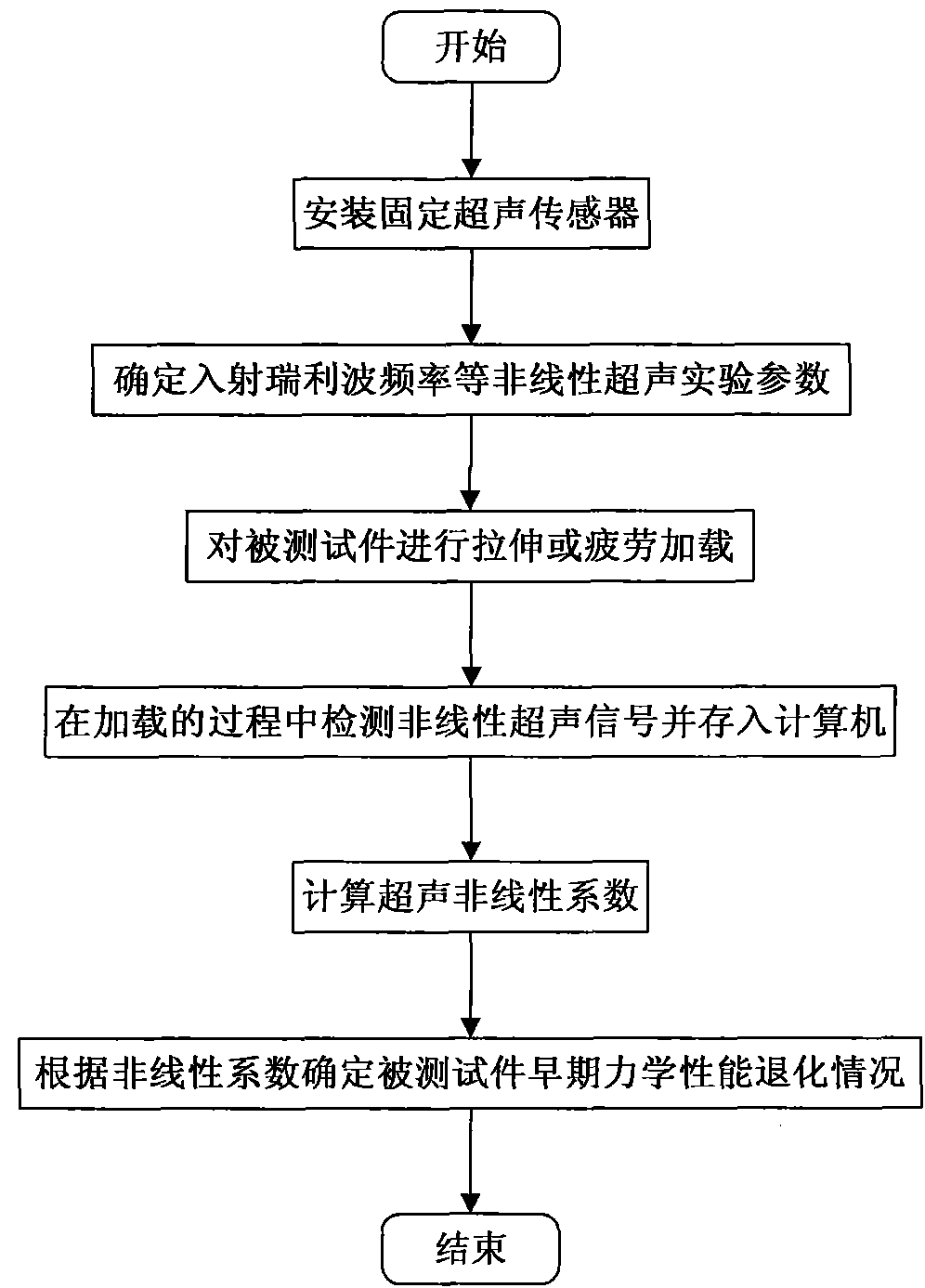

The invention discloses a method for detecting early-stage mechanical property degradation of a material by utilizing nolinear rayleigh wave, belonging to the field of nondestructive testing. The invention comprises the following steps: inputting frequency, periodicity and other parameters of a selected transmission signal to a signal generator to generate a required single sound signal, and determining the incident angle theta of the transmission signal according to the wave speed of a piece to be tested; collecting a non-linear Rayleigh wave signal in equal time intervals in the stretching or fatigue loading process of the piece to be tested; and carrying out Fourier transform to obtain basic wave amplitude and secondary harmonic amplitude, computing the ultrasound non-linear coefficient beta, and knowing the early-stage mechanical property degradation of the piece to be tested according to beta. In the invention, a sensor is directly arranged at the edge of the piece to be tested to transmit and receive Rayleigh wave to improve the excitation and receiving efficiencies of the signal and decrease the non-linear influence brought by the coupling of the sensor and the piece to be tested; and both the excitation and the receiving adopt the piezoelectric sensor, thus being more applicable to engineering actual situation, and realizing continuous on-line detection on the piece to be tested.

Description

A Method for Detecting Early Mechanical Property Degradation of Materials Using Nonlinear Rayleigh Waves technical field The invention relates to a method for non-destructive detection of early mechanical performance degradation of metal materials by using nonlinear Rayleigh waves, belonging to the field of non-destructive detection. Background technique It is a very common phenomenon that the mechanical properties of mechanical parts degrade due to long-term tensile, compressive or alternating loads, and eventually fracture failure. The degradation of mechanical properties of metal parts is mainly divided into three stages at the micro level: the generation of a large number of dislocations and the formation of resident slip bands, the increase of slip bands and the nucleation and growth of microcracks, the generation of macrocracks, and finally fracture failure. For well-designed structural elements, the first and second stages typically account for 60% to 80% of the ov...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N29/04G01N29/14

Inventor 吴斌颜丙生李佳锐何存富

Owner BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com