Industrial model predictive control method realizing dynamic optimization based on linear programming

A technology of model predictive control and dynamic optimization, applied in adaptive control, general control system, control/regulation system, etc., can solve problems such as poor practicability, high computational complexity, and long time consumption

Inactive Publication Date: 2010-08-25

ZHEJIANG UNIV OF TECH

View PDF0 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to overcome the shortcomings of high computational complexity, time-consuming and poor practicability in the dynamic optimization process of the existing industrial model predictive control method, the present invention provides a dynamic optimization method based on linear programming that simplifies calculation, shortens the calculation cycle, and has good practicability. industrial model predictive control method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

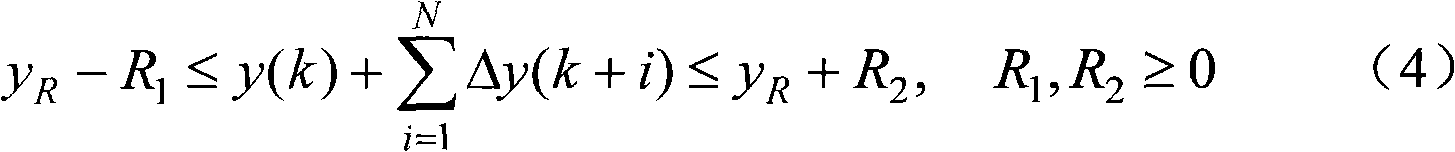

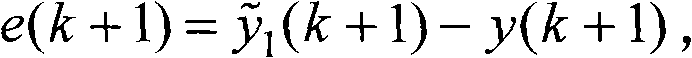

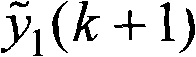

Login to View More Abstract

An industrial model predictive control method realizing dynamic optimization based on linear programming comprises the following steps: 1) carrying out steady state target optimization: computing the expected target value output in a controlled way in the steady state according to the input quantity of the sampling period; and 2) carrying out dynamic optimization: 2.1) obtaining step response models of the industrial process by a least square method, wherein the step response models are established in N-numbered periods; 2.2) predicting the output quantity at each future moment from the k+1 moment, referring to formula (2); 2.3) ensuring the input and the output in the dynamic process to be in own upper and lower bound ranges, referring to formula (3), setting target constraint, referring to formula (4) and creating the following performance indexes, referring to formula (5); forming the dynamic optimization problem by combining the formulas (2), (3), (4) and (5), solving all the control increments deltau(i) by linear programming, wherein i=0, 1,..., N-m-1, and then substituting the control increments into the formula (2) to compute the predictive output values y(k+1), y(k+2),..., y(N). The method simplifies computation, shortens the computation period and is good in practicability.

Description

technical field The invention relates to an industrial model predictive control method, in particular to a predictive control method for constraining dynamic process input and output, which can be applied to process industrial control, such as papermaking, food processing, petrochemical and other industries. Background technique The existing dynamic matrix control is to generate a non-parametric model offline through the identification method of the non-parametric model. Usually, a discrete FIR (finite impulse response) model is used to obtain the model coefficients after processing and verification. optimization and dynamic control. The dynamic matrix control algorithm is divided into two steps: the first is the steady-state target optimization step, an independent local steady-state optimization is performed to calculate the expected target value of the steady-state controlled output, and this step generally uses linear programming; The step of dynamic optimization is to...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G05B13/04

Inventor 张端高岩邹涛何熊熊丁宝苍

Owner ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com