an electronic motor

An electronic and stator technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of high cost of metal shell, large eddy current heat loss, affecting motor efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

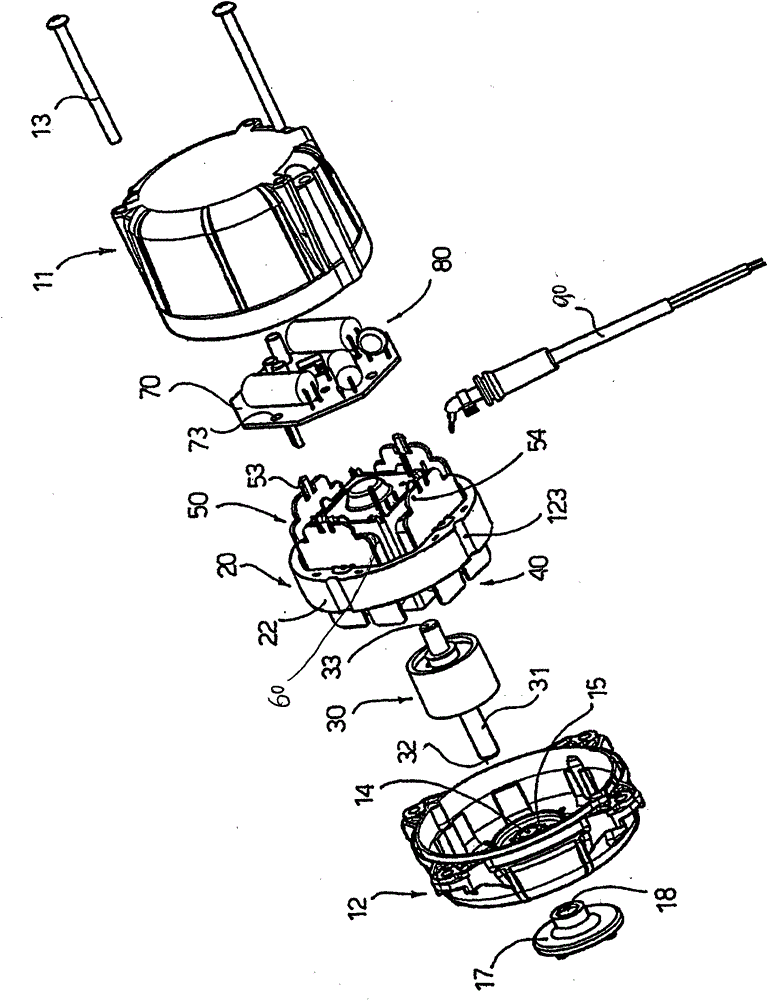

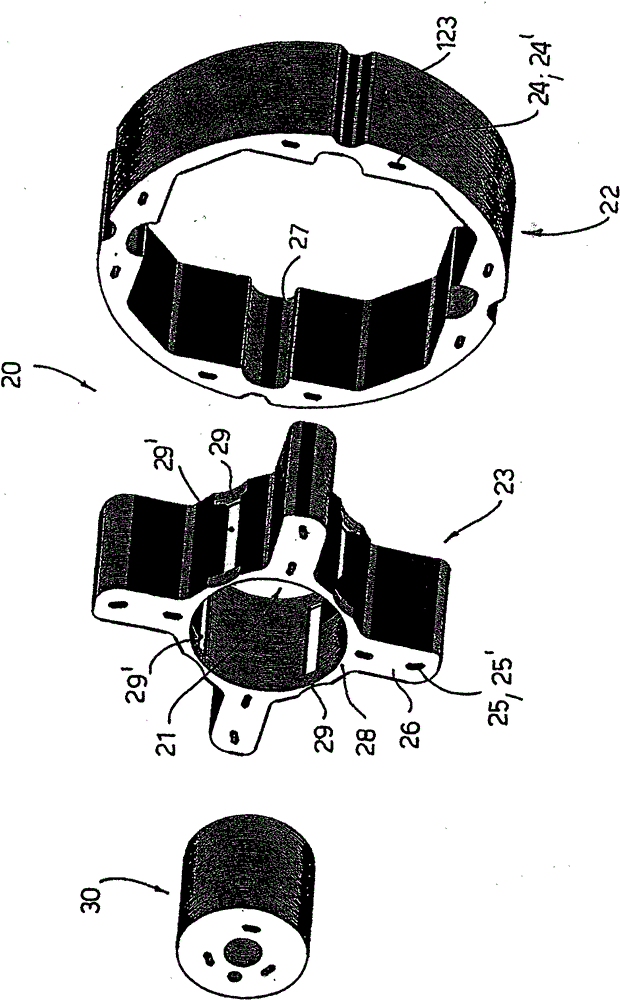

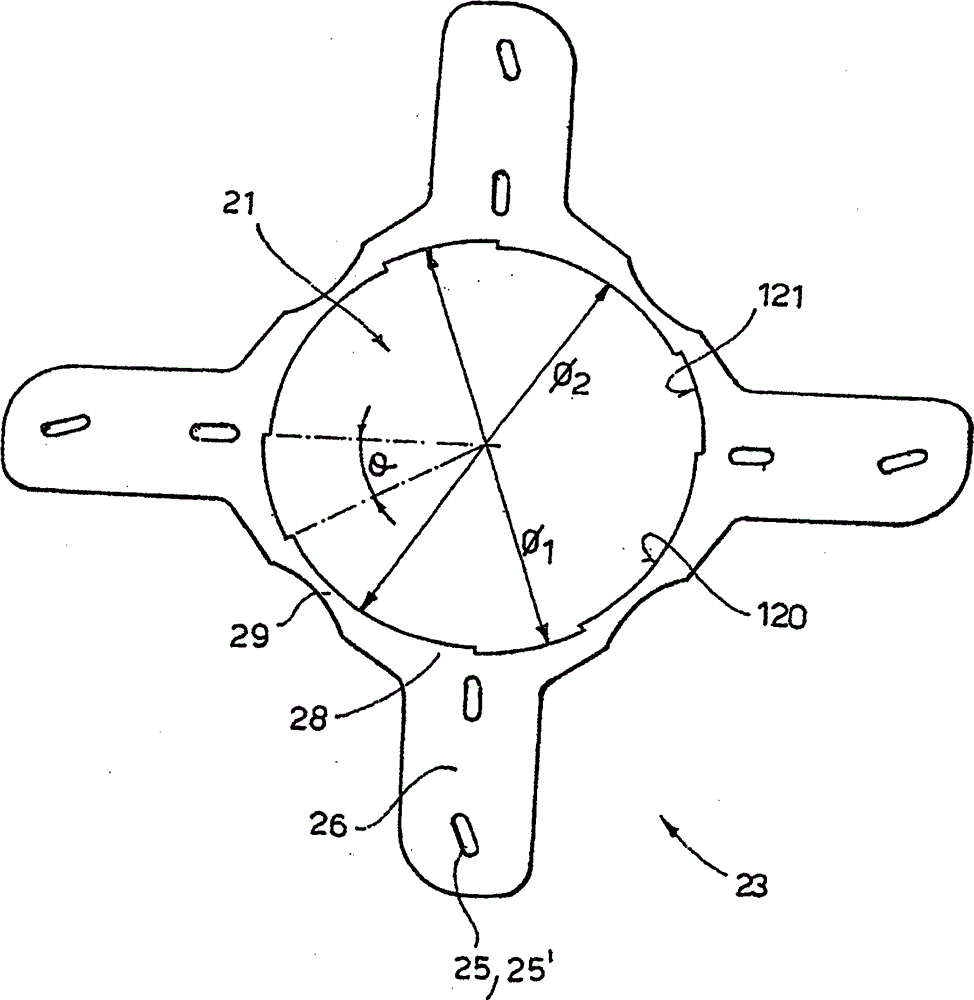

[0033] figure 1 , 2 , 3, 4, 5, and 6, the electronic motor of the present invention includes a front half shell 12, a rear half shell 11, a stator 20 with a winding 60, a rotor 30 with a shaft coupling 31, and a rear insulating support 50. The circuit board 70 and the power cord 90 installed on the rear insulating bracket 50. The stator 20 is composed of a stator fork 22 and a pole piece 23. A through hole 21 is provided in the middle of the pole piece 23, and pole shoes 28 are extended around it. The pole shoe 28 is provided with a radial electrode 26, and the inside of the stator fork 22 is provided with a slot 27 adapted to the pole piece electrode 26. The stator fork 22 and the pole piece 23 are plugged together through the slot 27 and the electrode 26. The pole shoe 28 has a large arched edge 120 on which a recess 121 is provided, the inner diameter of which is slightly larger than the inner diameter of the edge of the pole shoe 28 . The size of the above-mentioned conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com