Bioactive chilli sauce

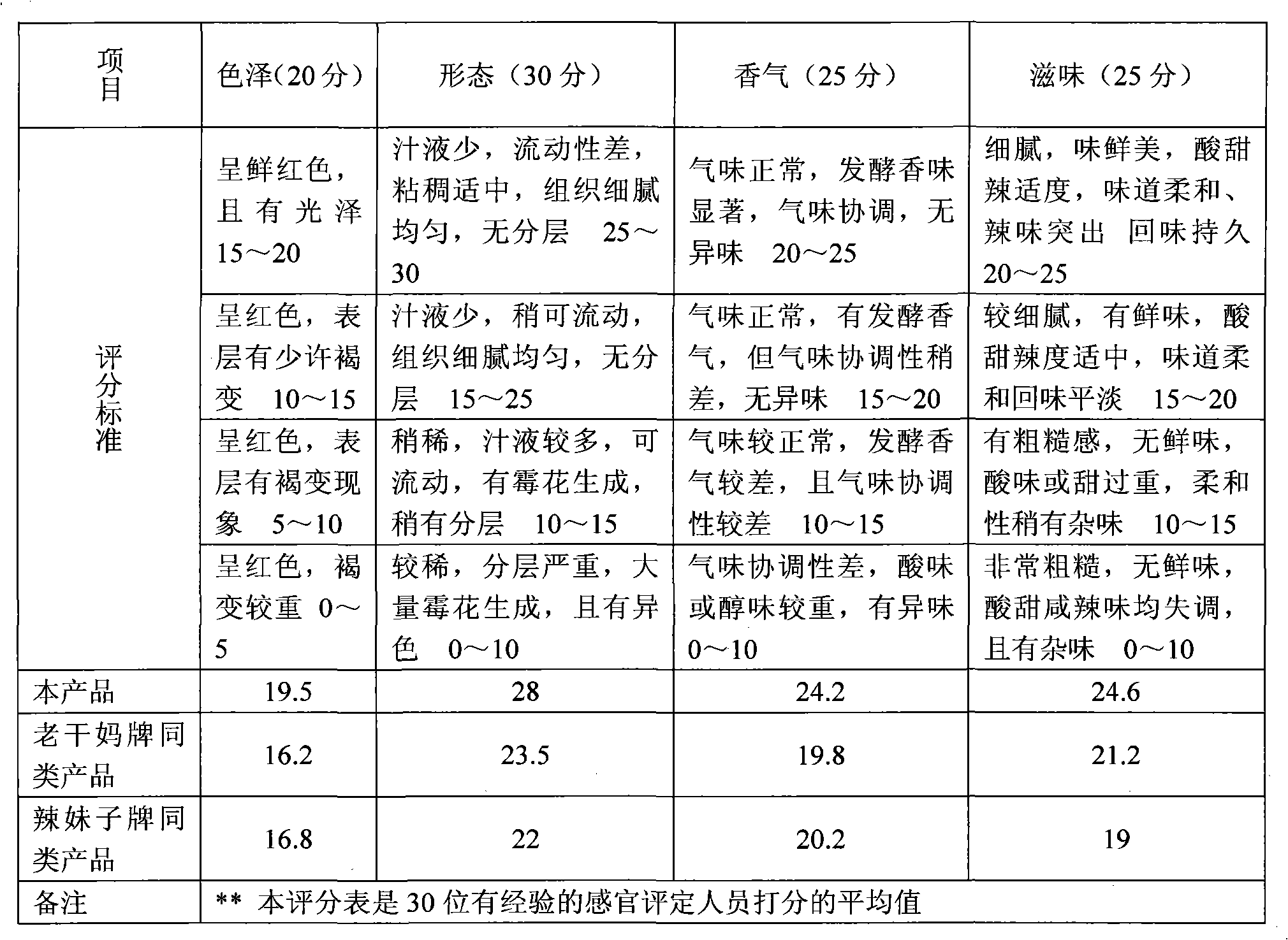

A biologically active, chili sauce technology, applied in the field of chili sauce, can solve the problems of insufficient bright red luster, poor odor coordination, poor fermentation aroma, etc., and achieve the effects of rich and long-lasting aroma, soft texture, and increased color and aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1) 80 kilograms of capsicums are beaten into pulp, then inoculated with lactic acid bacteria, the inoculation amount is 3% (the number of lactic acid bacteria in the medium is 10 8 CFU / g), fermented at 35°C for 20 hours, then took it out and placed it at 20°C for 20 hours for post-ripening fermentation. The lactic acid bacterium is Lactobacillus bulgaricus, purchased from China General Microorganism Culture Collection and Management Center.

[0044] 2) Pour 2 kg of sugar into 15 kg of sunflower oil, heat to 90°C and cook for 2 minutes. At this time, the sugar will change color and have a fragrance. Stir continuously during this period, then heat up to 140°C, and add 9 kg of ginger, 21 kg of garlic, 19 kg of onion, 41 kg of soy sauce, each ingredient should be boiled at 140°C for 1 minute before adding the next ingredient, after the soy sauce is boiled at 140°C for 2-3 minutes, add fermented peppers, 140°C Boil for 3-5 minutes, and finally add 2 kg of salt and 3 kg of m...

Embodiment 2

[0047] 1) 120 kilograms of peppers are beaten into pulp, and then inoculated with lactic acid bacteria, the inoculation amount is 2% (the number of lactic acid bacteria in the medium is 10 8CFU / g), fermented at 35°C for 25 hours, then took it out and placed it at 20°C for 16 hours for post-ripening fermentation. The lactic acid bacterium is Lactobacillus bulgaricus, purchased from China General Microorganism Culture Collection and Management Center.

[0048] 2) Pour 4 kg of sugar into 25 kg of sunflower oil, heat to 50°C and cook for 2-3 minutes. At this time, the sugar will change color and have a fragrance. Stir continuously during the period, then heat up to 120°C, and put in 11 kg of Ginger, 19 kg of garlic, 21 kg of onion, 39 kg of soy sauce, each ingredient should be boiled at 120 for 1 minute before adding the next ingredient, wait for the soybean paste to boil for 2-3 minutes, then add pepper, and boil for 3 minutes at 120 -5 minutes, finally add 4kg of salt and 1kg o...

Embodiment 3

[0051] 1) 100 kilograms of peppers are beaten into pulp, and then inoculated with lactic acid bacteria, the inoculation amount is 2.8% (the number of lactic acid bacteria in the medium is 10 8 CFU / g), fermented at 35°C for 23 hours, then took it out and placed it at 20°C for 19 hours for post-ripening fermentation. The lactic acid bacterium is Lactobacillus bulgaricus, purchased from China General Microorganism Culture Collection and Management Center.

[0052] 2) Pour 3 kg of sugar into 20 kg of sunflower oil, heat to 70°C and cook for 2-3 minutes. At this time, the sugar will change color and have a fragrance. Stir continuously during the period, then heat up to 130°C, and put in 10 kg Ginger, 20 kg of garlic, 20 kg of onion, 40 kg of soy sauce, each ingredient should be boiled at 130°C for 1 minute before adding the next ingredient, wait for the soybean paste to be boiled at 130°C for 2-3 minutes, then add pepper, 130 ℃ for 3-5 minutes, and finally add 3 kg of salt and 2 k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com